Improved trailer robot

An improved robotic technology, applied in the field of robotics, can solve problems such as accidents, winding turntables reversed, easy to fall out, etc., to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

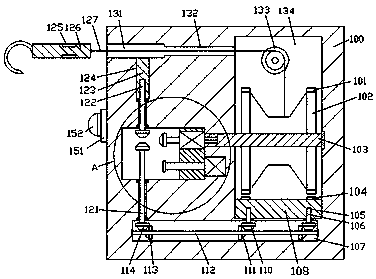

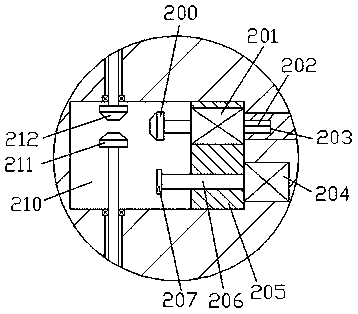

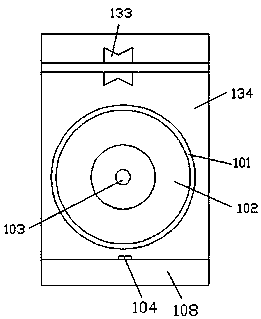

[0013] Combine below Figure 1-3 The present invention will be described in detail.

[0014] refer to Figure 1-3 , an improved trailer robot according to an embodiment of the present invention, comprising a dragging base frame 100, a winding cavity 134 is provided in the inner wall of the right side of the dragging base frame 100, and a winding cavity 134 is provided on the left side of the winding cavity 134. The first transmission chamber 210 is provided in the said drag base frame 100, and the second transmission chamber 107 is extended to the right in the said drag base frame 100 on the lower side of the first transmission chamber 210, and the winding chamber 134 is provided with a first rotating shaft 103 extending left and right for rotation and cooperation, and the outer surface of the first rotating shaft 103 is fixed with a winding turntable 102 in the circumferential direction, and the winding cavity 134 on the upper side of the winding turntable 102 rotates Coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com