Operating handle

A technology of operating handle and driving mechanism, which is applied in the control field of loading and unloading machinery, can solve the problems of inability to switch signal feedback to the operator, inconvenient installation of a compact console, and heavy labor for the operator, saving manpower, material resources, structure, etc. Compact, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

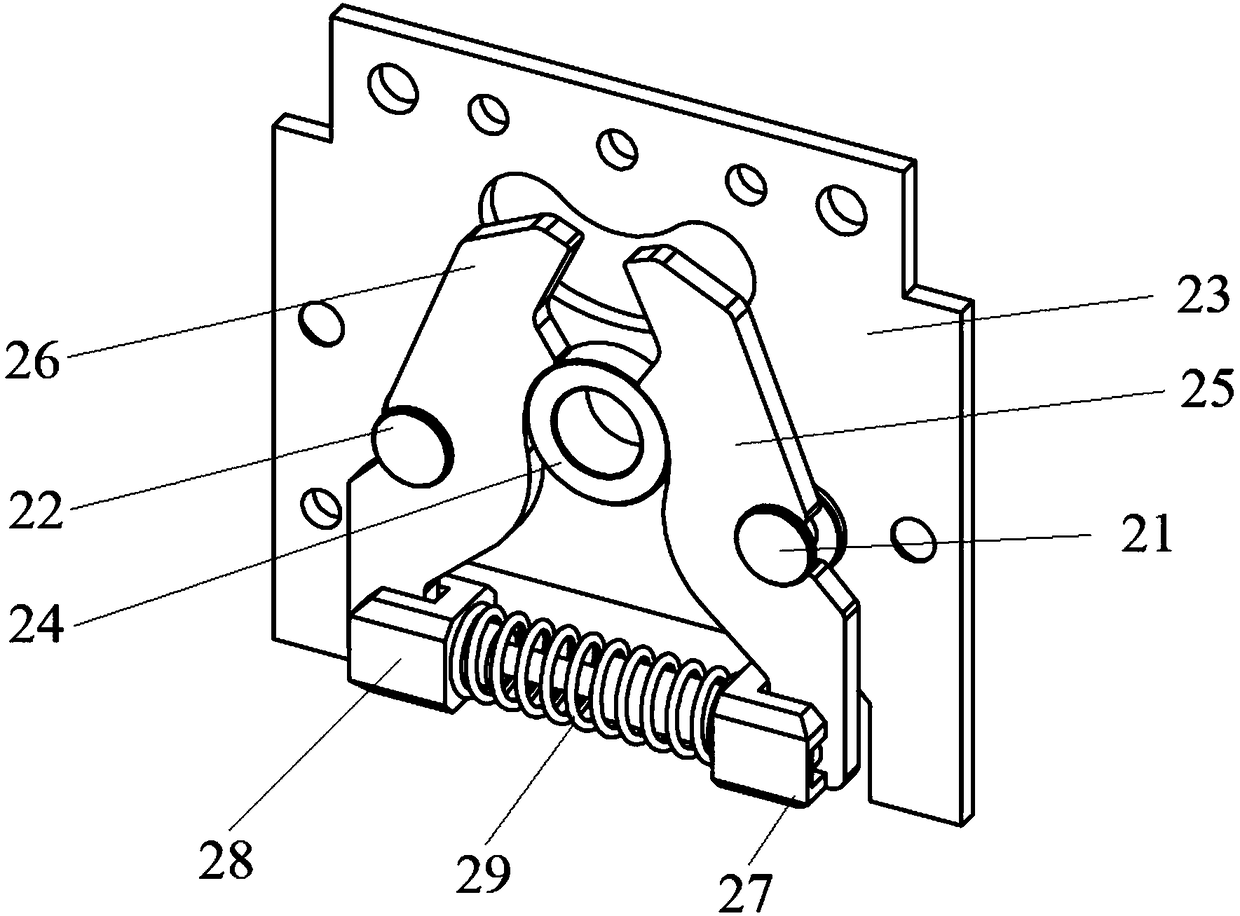

[0114] According to a preferred embodiment of the present invention, the reset assembly further includes a first clip 27 and a second clip 28 respectively connected to the bottom ends of the first paddle 25 and the second paddle 26,

[0115] A first connecting piece 29 is also provided between the first locking piece 27 and the second locking piece 28, and the connecting piece 29 provides an outward force to the first locking piece 27 and the second locking piece 28, so that the first A paddle 25 and a second paddle 26 are in contact with the bearing seat 24 .

[0116] In a further preferred embodiment, the first clamping part 27 and the second clamping part 28 are telescopic structures threaded together, preferably claws; the first connecting part 29 is elastic, preferably a spring.

[0117] Wherein, in the natural state, under the elastic action of the first connecting piece 29, the first clip 27 and the second clip 28 provide the bottom ends of the connected first paddle 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com