A kind of zno/c hollow microsphere and preparation method thereof

A microsphere and hollow technology, applied in the field of materials, can solve the problems of zinc oxide hollow microspheres, such as complicated process, harsh experimental conditions, and unsuitable for mass production, so as to improve the efficiency of electrochemical reaction and the performance of batteries, low cost, Uniform and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 2g of sodium alginate into a beaker, then add 200mL of deionized water, fully stir and dissolve at room temperature for later use.

[0039] (2) Weigh 2gZnCl 2 Add it to another beaker, add 200mL deionized water as well, stir until it is completely dissolved and set aside.

[0040] (3) Transfer the sodium alginate aqueous solution prepared in step (1) to a 500mL disposable medical infusion set, and drop it into the ZnCl 2 in the solution with continuous stirring to obtain translucent chelate precursor microspheres. After the dropwise addition is completed, the solution is continuously stirred for 4-5 hours, filtered with suction, and washed with deionized water for 3 times.

[0041] (4) The translucent chelate precursor microspheres prepared in step (3) were hydrothermally reacted in a hydrothermal kettle at 140° C. for 5 hours to obtain ZnO / C hollow microspheres.

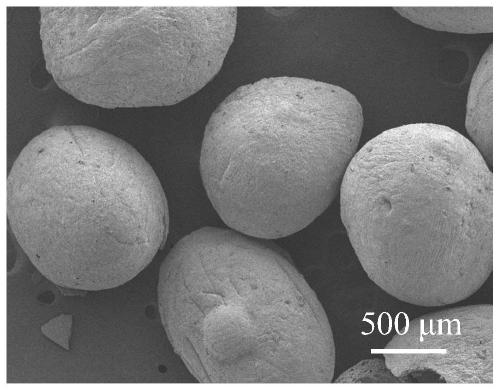

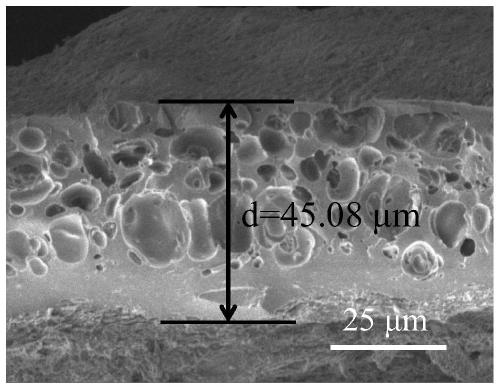

[0042] figure 1 For the SEM figure (bar=500um) of the ZnO / C hollow microsphere that embodimen...

Embodiment 2

[0044] (1) Weigh 2g of sodium alginate into a beaker, then add 200mL of deionized water, fully stir and dissolve at room temperature and set aside.

[0045] (2) Weigh 2g of ZnCl 2 Add it to another beaker, add 200mL deionized water, stir until it is completely dissolved and set aside.

[0046] (3) Transfer the aqueous solution of sodium alginate prepared in step (1) to a 500mL disposable medical infusion set, and drop it into the ZnCl 2 solution with continuous stirring to obtain translucent chelate precursor microspheres. After the dropwise addition was completed, the stirring was continued for 4-5 hours, and then it was suction-filtered and washed 3 times with deionized water.

[0047] (4) The translucent chelate precursor microspheres prepared in step (3) were hydrothermally reacted in a hydrothermal kettle at 160° C. for 5 hours to obtain ZnO / C hollow microspheres.

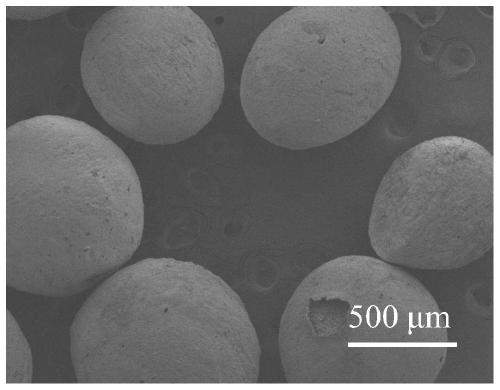

[0048] image 3 For the SEM figure (bar=500um) of the ZnO / C hollow microspheres prepared in embodiment 2,...

Embodiment 3

[0050] (1) Weigh 2g of sodium alginate into a beaker, then add 200mL of deionized water, stir and dissolve at room temperature for later use, if the dissolution rate is too slow, heat it appropriately to make it dissolve quickly.

[0051] (2) Weigh 2g of ZnCl 2 Add it to another beaker, add 200mL deionized water as well, stir until it is completely dissolved and set aside.

[0052] (3) Transfer the aqueous solution of sodium alginate prepared in step (1) to a 500mL disposable medical infusion set, and drop it into the ZnCl 2 solution with continuous stirring to obtain translucent chelate precursor microspheres. After the dropwise addition was completed, the stirring was continued for 4-5 hours, and then it was suction-filtered and washed 3 times with deionized water.

[0053] (4) The translucent chelate precursor microspheres prepared in step (3) were hydrothermally reacted in a hydrothermal kettle at 180° C. for 5 hours to obtain ZnO / C hollow microspheres.

[0054] Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com