A cleaning mechanism for electroplating tank

A technology for cleaning mechanism and electroplating tank, which is applied to electrolytic components, electrolytic process, cells, etc., can solve the problem of not being able to clean the bottom surface and side wall of the electroplating tank at the same time, and achieve the effect of being convenient for storage and placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

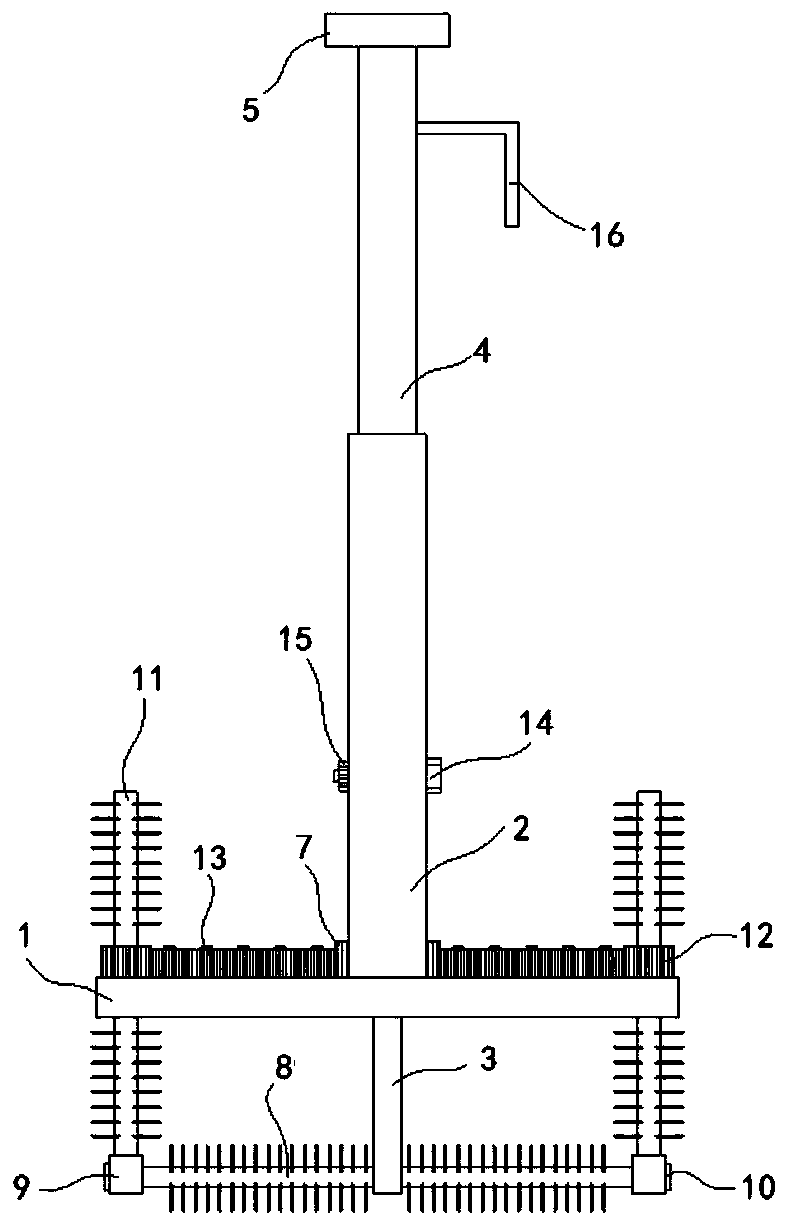

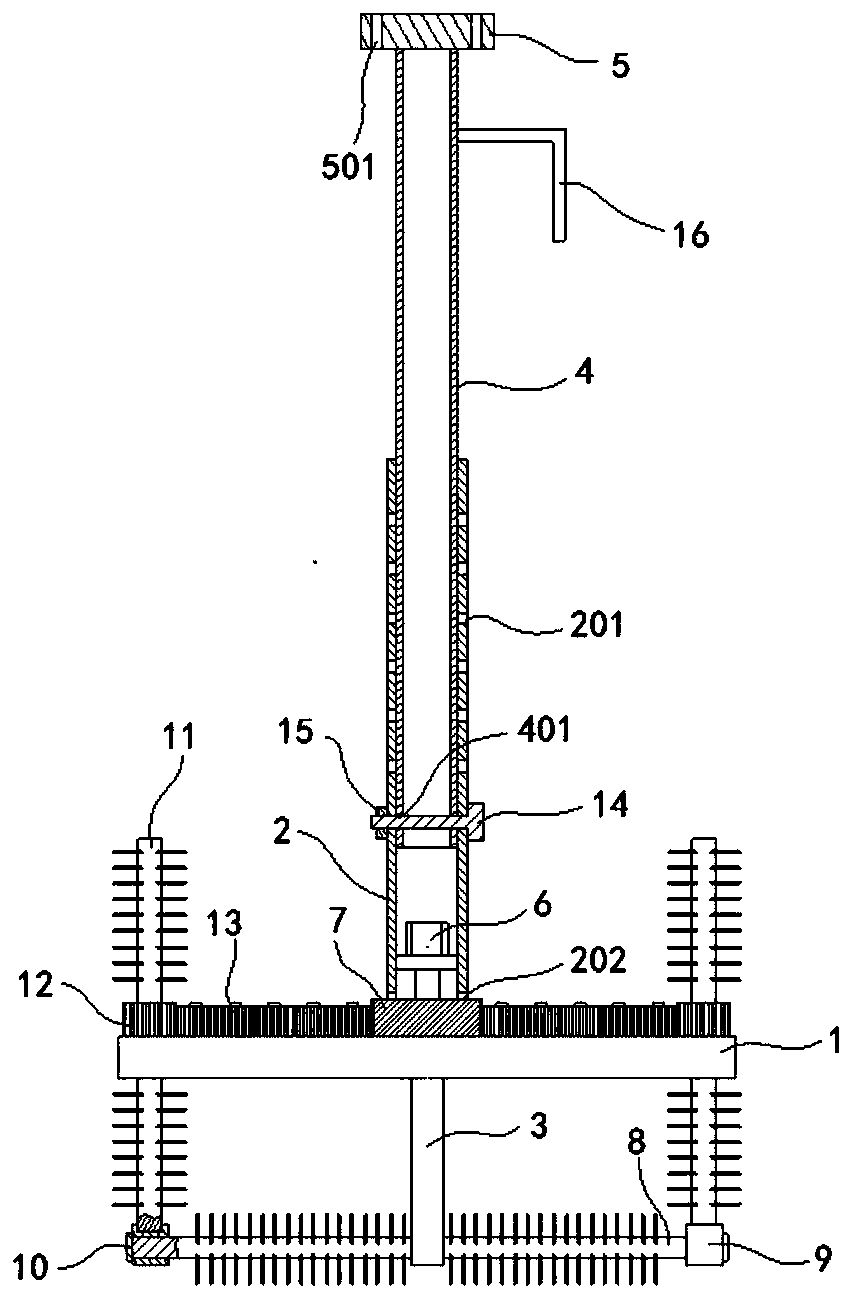

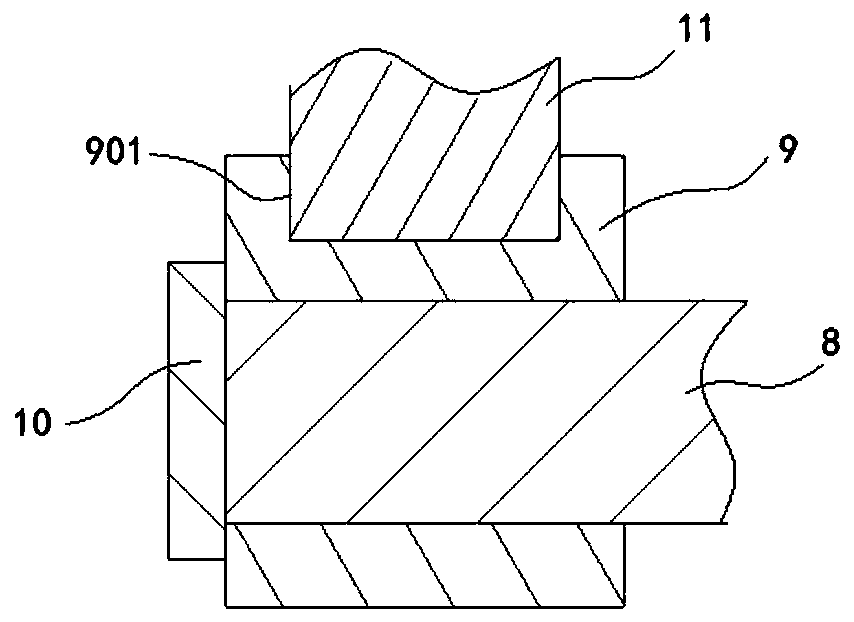

[0022] Such as figure 1 , figure 2 , image 3 Shown, a kind of cleaning mechanism for electroplating tank of the present invention comprises:

[0023] Horizontal pole 1, above the middle part of the pole 1 is formed with a vertical first connecting rod 2, and below the middle part of the pole 1 is formed with a vertical second connecting rod 3, the first connecting rod 2 is plugged with a vertical support rod 4, the upper end of the support rod 4 is formed with a horizontal mounting plate 5, the lower end of the first connecting rod 2 is provided with a rotating motor 6, and the output of the rotating motor 6 The shaft is connected with driving gear 7. A plurality of first positioning holes 201 are formed on the opposite side walls of the first connecting rod 2, and second positioning holes 401 are formed on the two opposite side walls of the lower end of the support rod 4, through which the positioning bolts 14 pass. A positioning nut 15 is screwed behind the second posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com