Flotation concentrate pulp delivery pump tank assembly

A technology for flotation concentrate and conveying pump, which is applied to pump elements, variable displacement pump parts, parts of pumping devices for elastic fluids, etc. The effect of the probability of a large spill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The technical scheme is suitable for the situation that the slurry in the flotation concentrate has little foam or little viscosity.

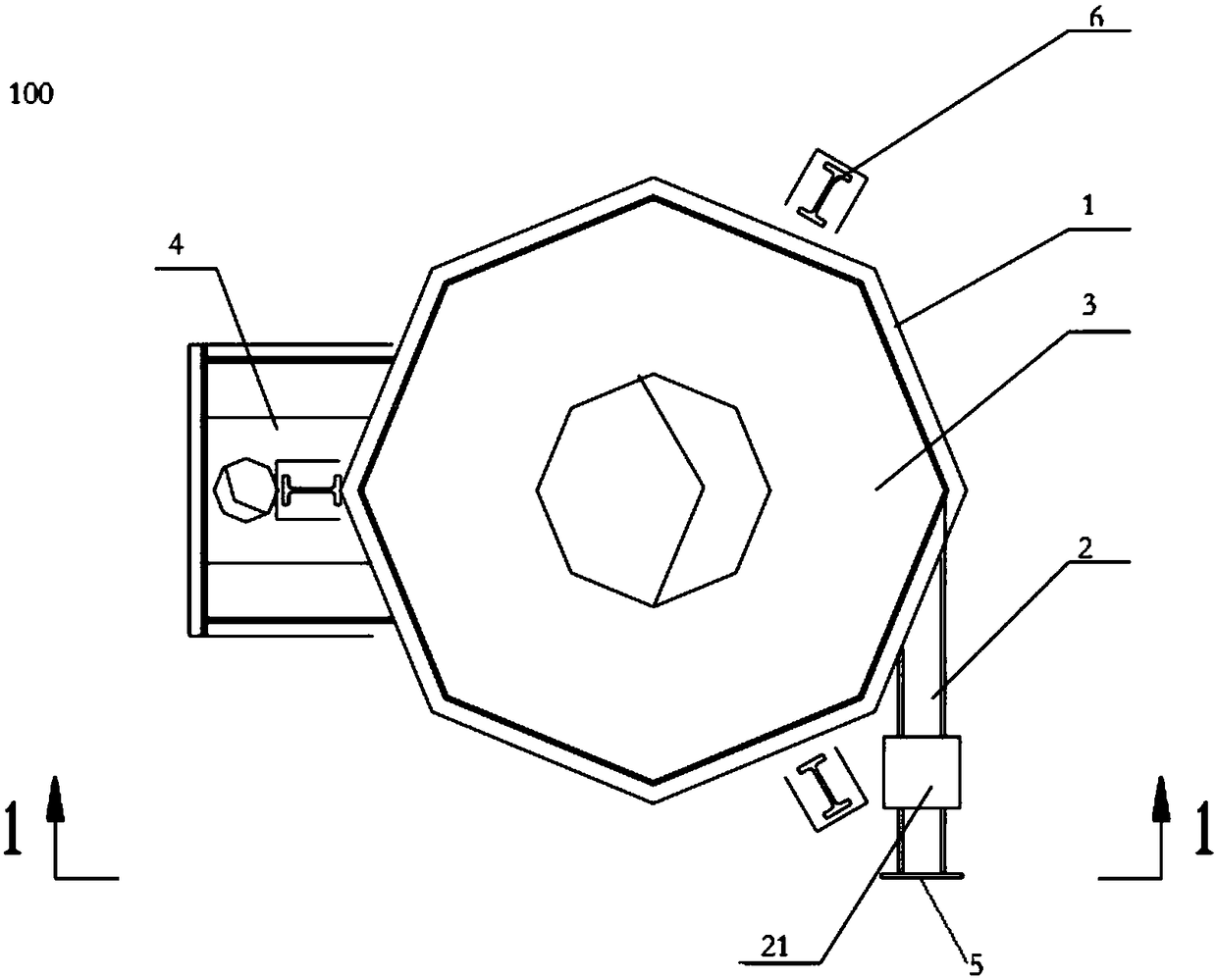

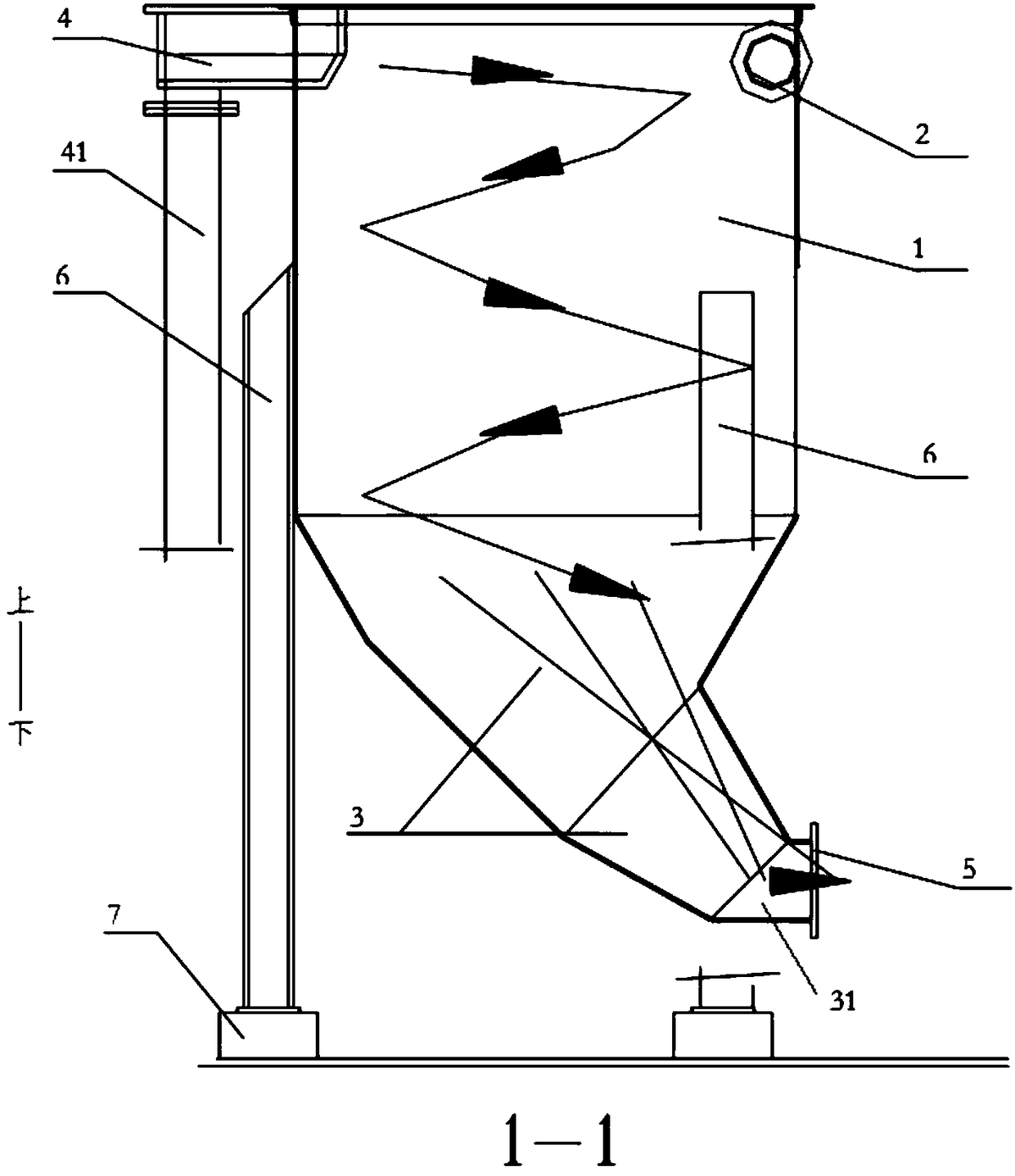

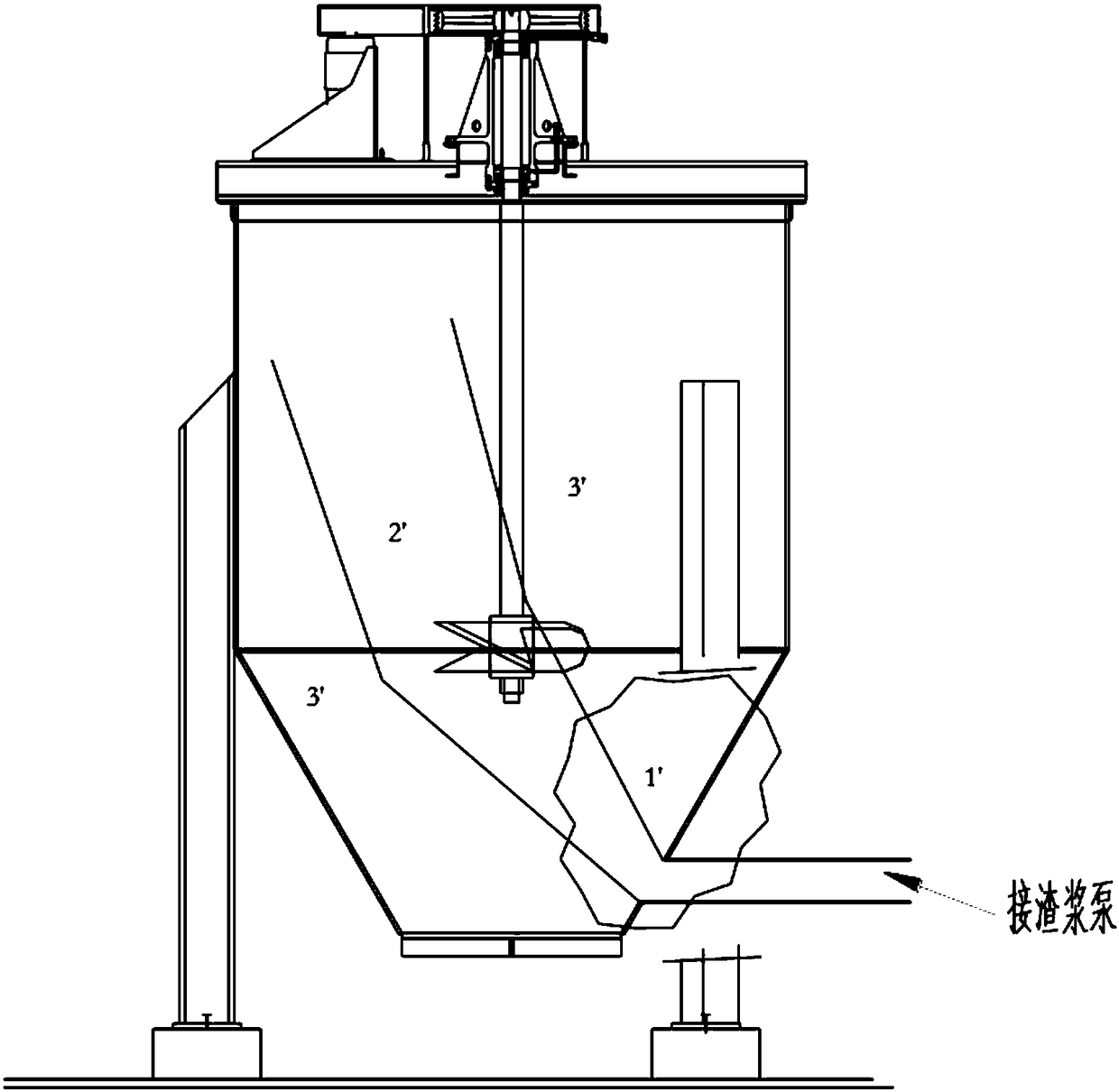

[0064] The flotation concentrate ore slurry delivery pump pool assembly 100 includes a pump pool body 1, the pump pool body is mainly a cylindrical body, and the upper part of the cylindrical body is provided with a slurry overflow collection device 4 and a horizontally arranged feeding pipe 2 for feeding The feed pipe 2 is arranged horizontally and tangentially along the cylindrical shell. The ore feeding method adopts self-flow feeding, and the ore slurry is fed in horizontally along the cylinder body by gravity, and the initial velocity entering the pump pool body 1 is relatively small, and the feeding point is tangent to the pump pool body wall and is subjected to the action of the pump pool body wall. Smooth, so there will be no secondary generation of pulp foam that affects the transportation. The lower part of the pump pool body ...

Embodiment 2

[0066] The technical scheme is suitable for the situation that there are many slurry foams and high viscosity in the flotation concentrate.

[0067] According to the embodiment of the present invention, the pump pool assembly 100 for flotation concentrate slurry delivery includes a pump pool body 1, the pump pool body 1 is mainly a cylindrical cylinder, and the upper part of the cylindrical cylinder is provided with a slurry overflow collection device 4 and a horizontal arrangement The feeding pipe 2 is provided horizontally and tangentially along the cylindrical shell. The ore feeding method is to use pressure feeding, that is, the ore feeding pipe 2 is equipped with a booster device 21 or the height difference configuration of the ore feeding is increased, so that the ore pulp has a suitable initial velocity after entering the cylinder through the feeding pipe 2, and the ore pulp is fed by the upper part. To the lower part, it flows spirally along the wall of the pump pool b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com