Electric linear motion valve actuator

A straight-stroke, actuator technology, applied in valve details, valve devices, engine components, etc., can solve the problems of slow execution speed, high cost of construction and maintenance, complex structure, etc., to improve accuracy and stability, simple structure, The effect of low use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

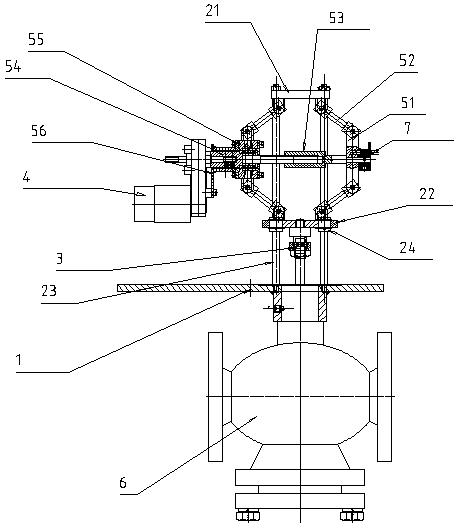

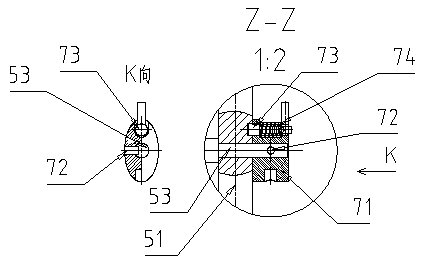

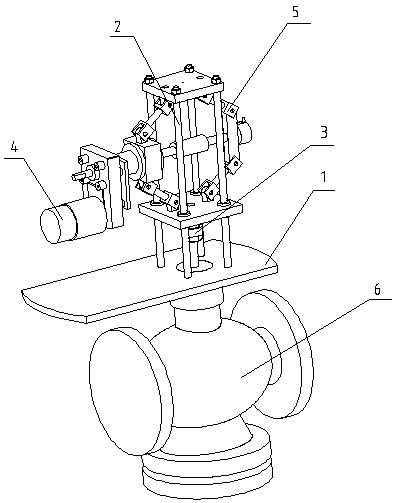

[0017] Such as Figure 1-3 As shown, the electric straight-stroke valve actuator includes a valve body connecting seat 1, a guiding mechanism 2, a valve core connecting piece 3, a motor 4 and an actuator 5, and the guiding mechanism 2, the valve body connecting seat 1 and the valve body 6 are fixedly connected in order to form a whole, the top of the guide mechanism 2 is fixedly provided with a supporting top plate 21, and a movable slide plate 22 that can move up and down along the guide mechanism 2 is installed through it. The spool is fixedly connected, the upper end of the actuator 5 is movably connected with the support top plate 21, and the bottom end is movably connected with the moving slide 22. The actuator 5 is connected with the motor 4, and is driven by the motor 4 to move left and right in the horizontal direction, The opening and closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com