Method for quickly analyzing punching crack defects of ultra-deep drawing steel plate

A rapid analysis and ultra-deep drawing technology, applied in material inspection products, testing metals, etc., can solve problems such as deviation of results, and achieve the effect of fast inspection speed, high efficiency and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

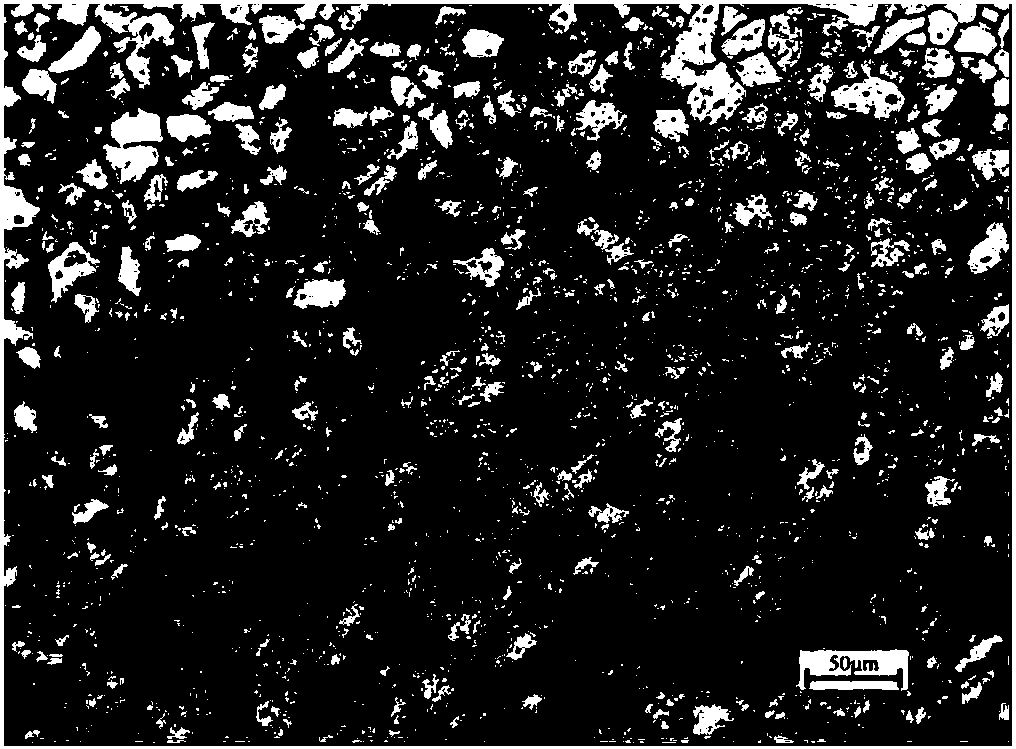

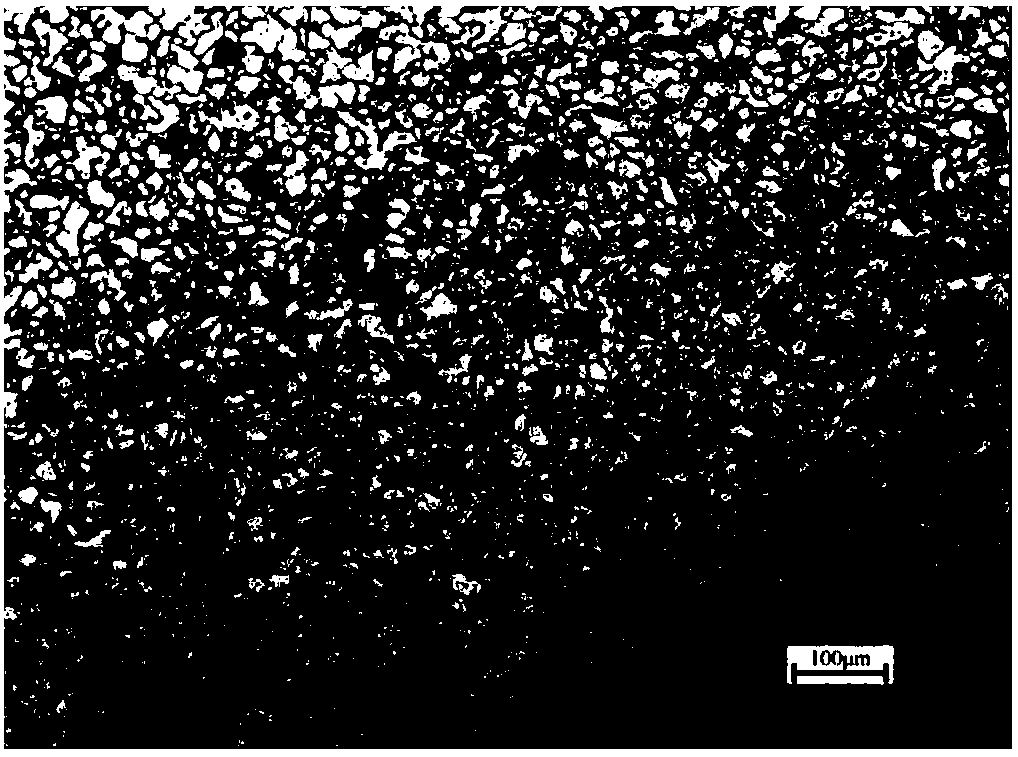

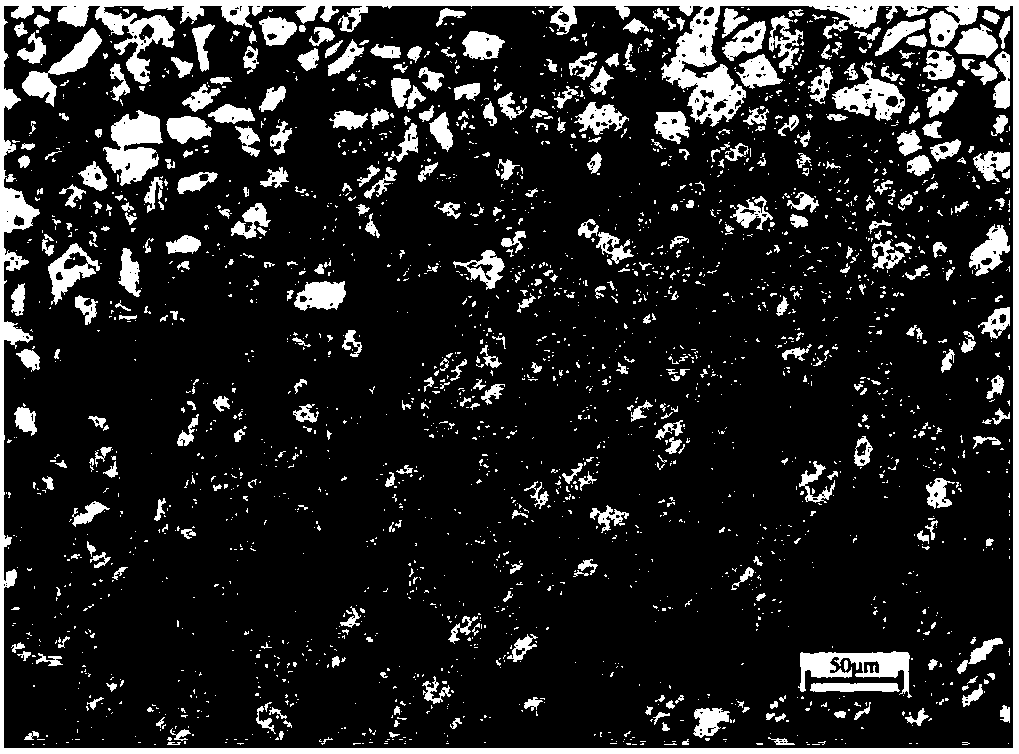

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0036] The method for quickly analyzing the cracking defects of ultra-deep-drawn steel plates is to divide the cut steel plates for forming into N fan-shaped areas with the center point of the steel plate as the center of the circle, and divide the center line of each fan-shaped area into M equal parts. Measure the hardness value at each equal point, then calculate the hardness extreme value deviation and influence factor, and finally judge whether the steel plate has the possibility of punching cracks or ear defects; N and M are integers, and the value range of N is 6 to 12 , and the value range of M is 2-5.

[0037] When testing the hardness value of each equal point, when the thickness of the steel plate is ≥ 2.5mm, the hardness test uses the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com