Ageing oven and ageing method

An aging furnace and furnace body technology, applied in measurement devices, instruments, environmental/reliability testing, etc., can solve the problems of low signal utilization efficiency, waste of resources, and high cost of OLED display aging test, and reduce the cost of aging test. , The effect of solving the waste of resources and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

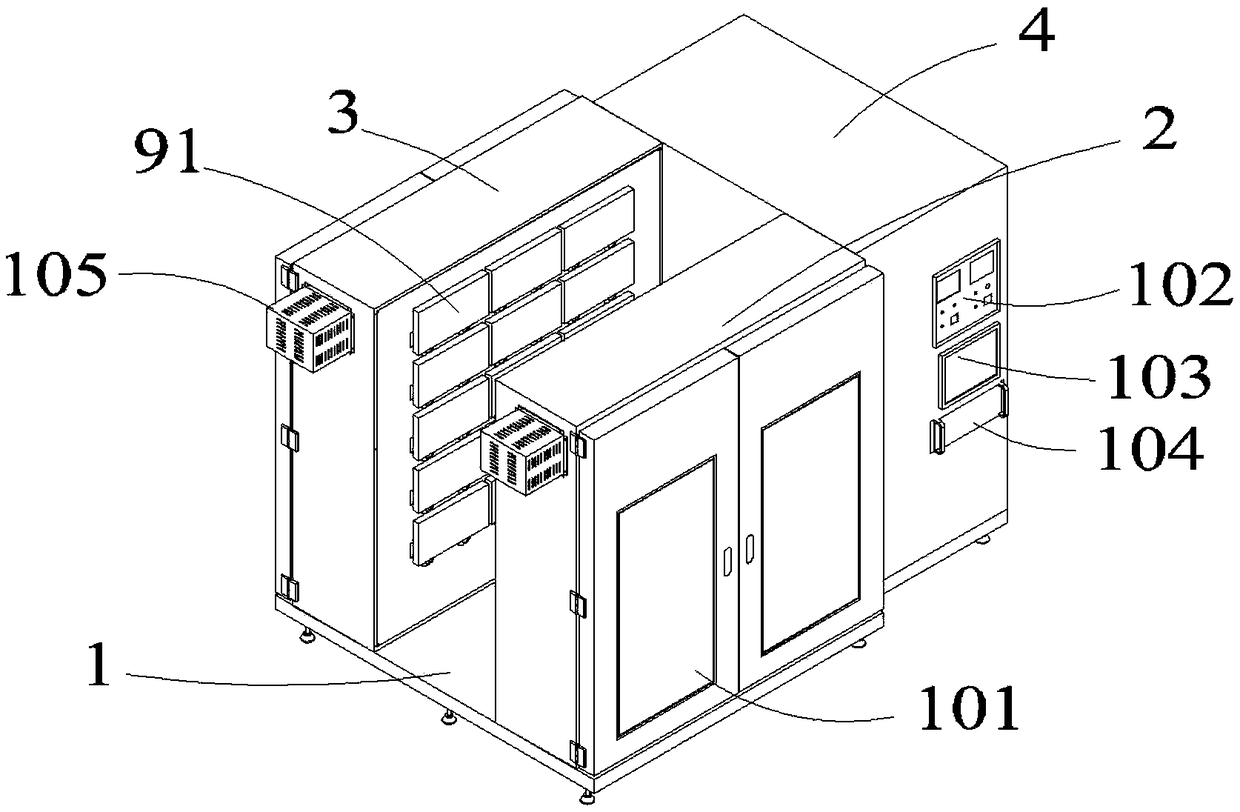

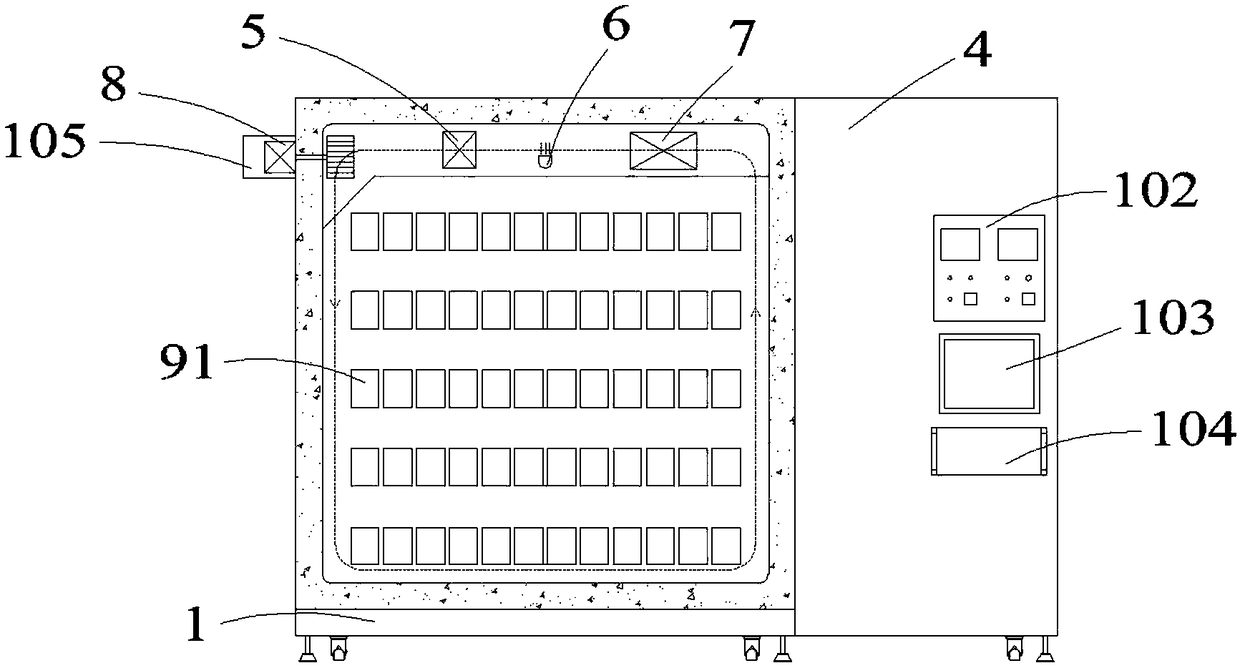

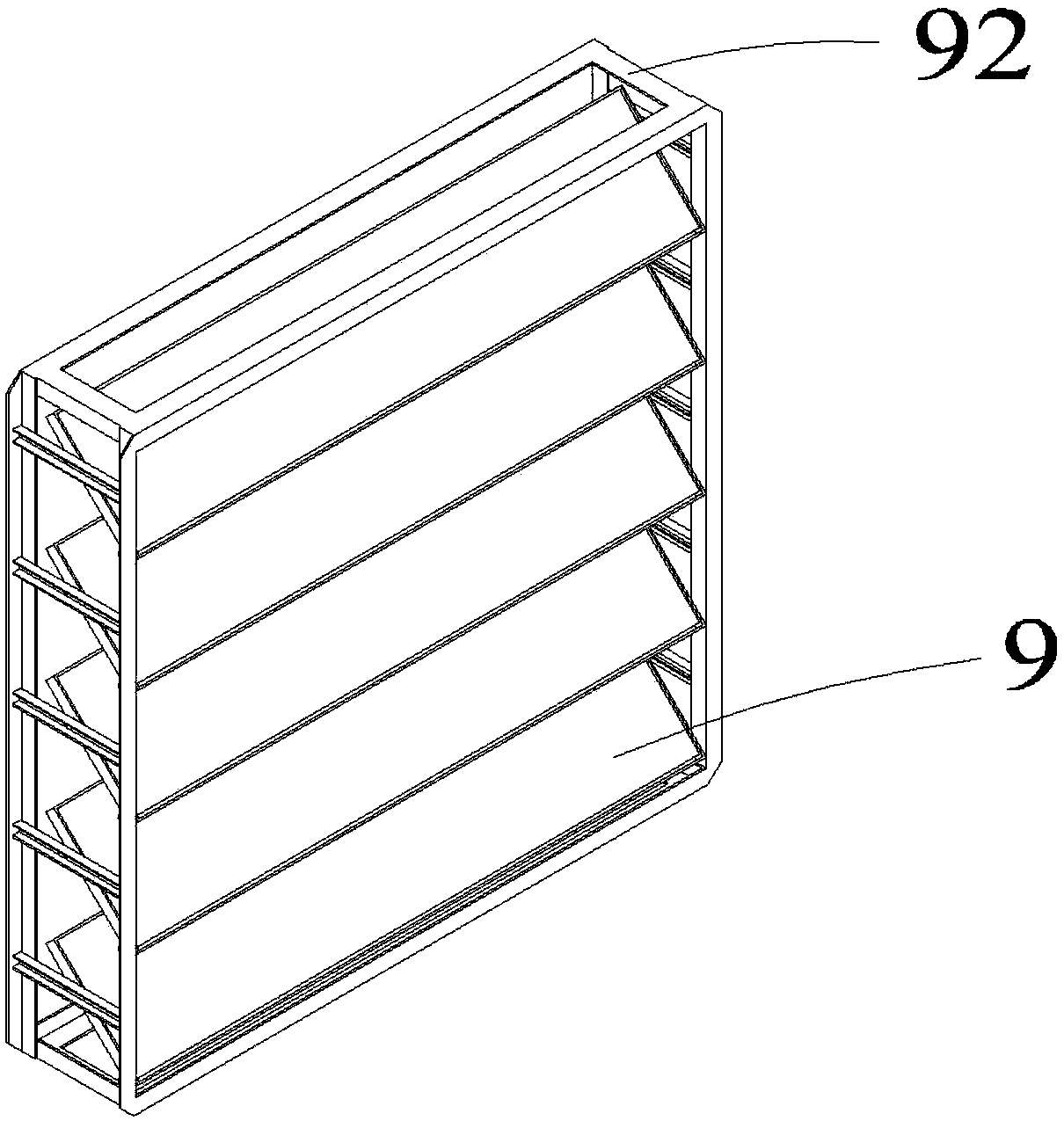

[0020] See Figure 1 to Figure 3 The aging furnace shown in the present invention includes a base 1, a first furnace body 2, a second furnace body 3 and a control room 4, and the first furnace body 2 and the second furnace body 3 are relatively arranged on the base 1, The control room 4 is arranged on one side of the two furnace bodies. Both the first furnace body 2 and the second furnace body 3 are provided with a heater 5 , a humidifier 6 , an evaporator 7 , a motor 8 , a bracket 9 and m test fixtures 91 . The control room 4 is provided with a power distribution room (not shown) and a machine room (not shown). The two furnace bodies have an outer surface 10 on which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com