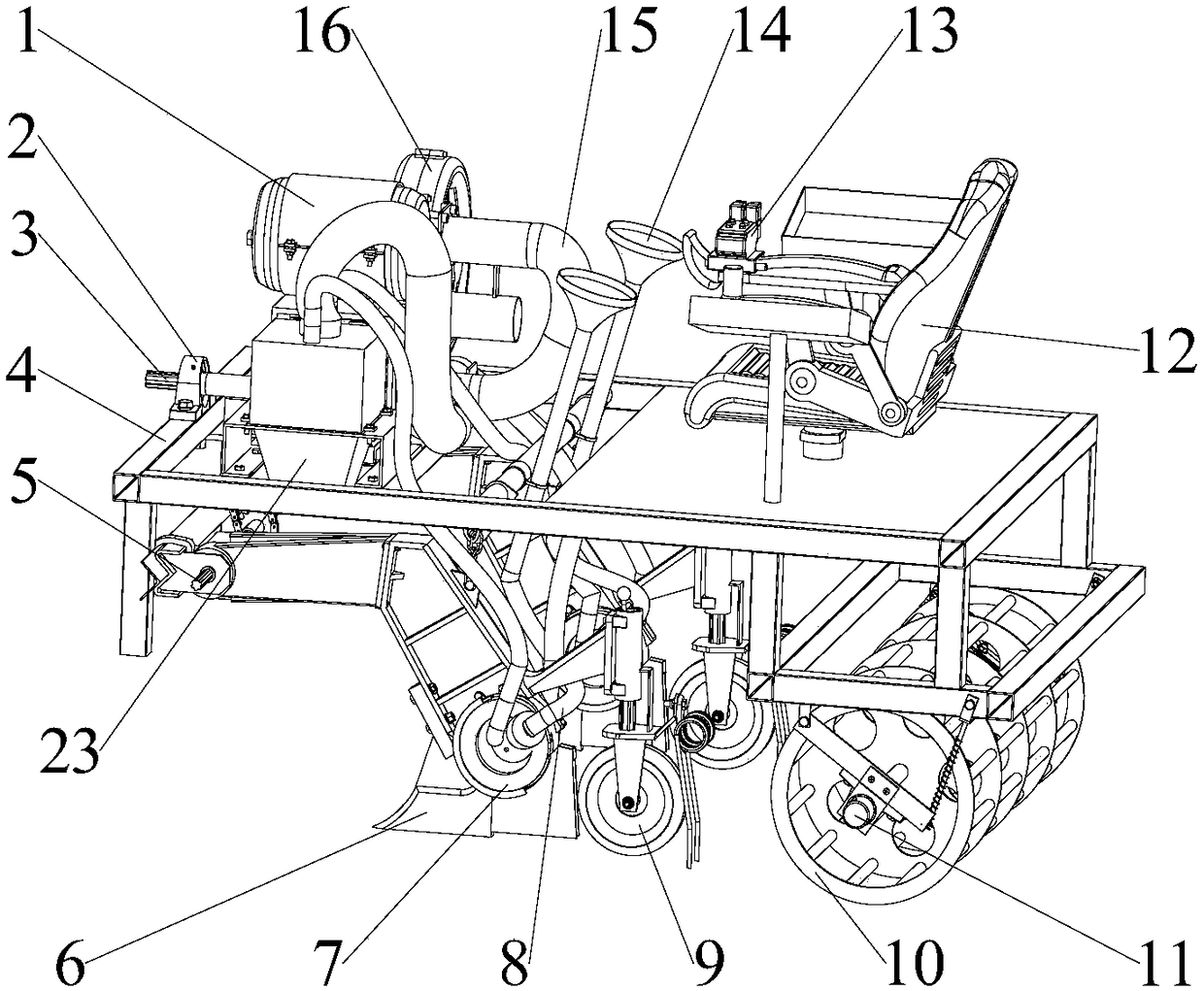

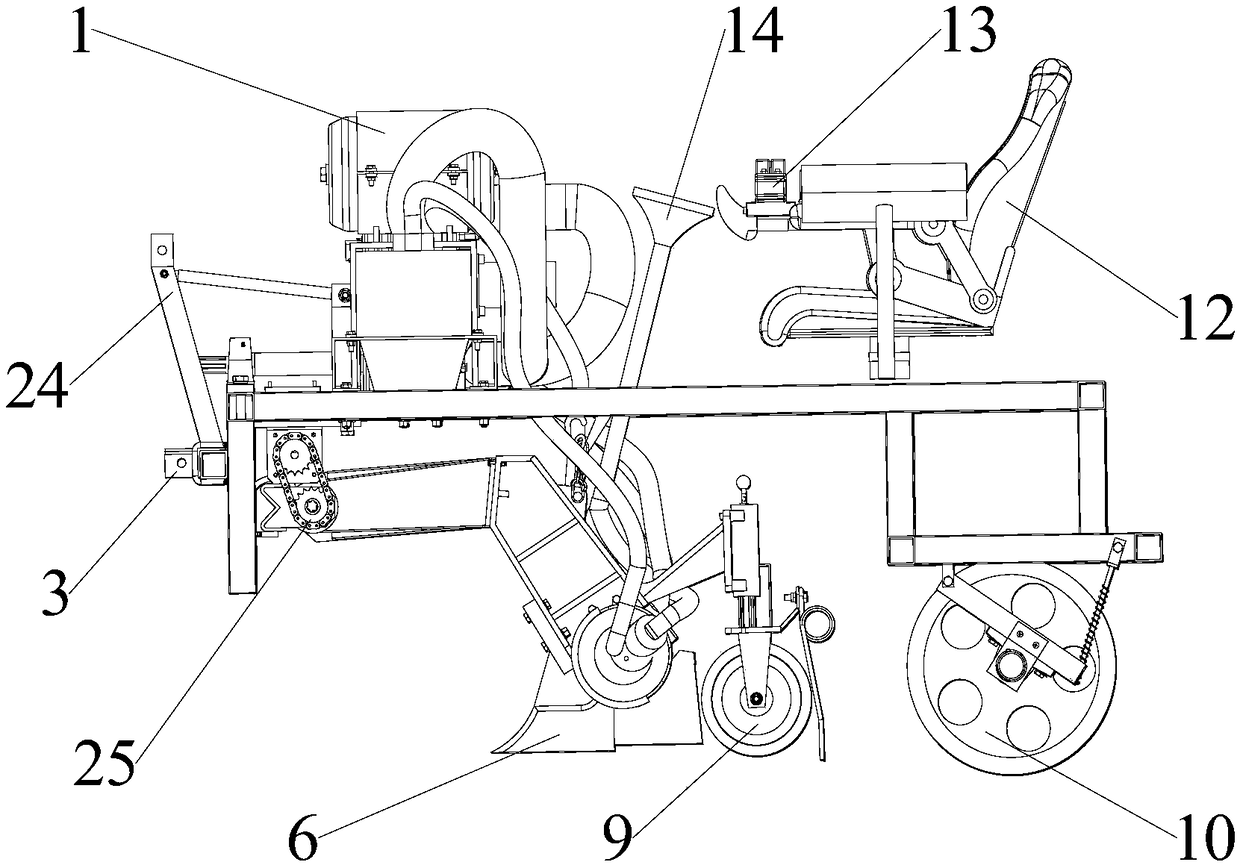

Automatic control plot seeding machine

A technology for seeders and plots, which is applied to single-seed seeders, parts of seeders, and sowing. It can solve the problems of easy mixing, complicated control of plant spacing and row spacing, clearing and damaging seeds, etc., so as to improve the utilization rate of seeds and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The steps for plot seeding are as follows:

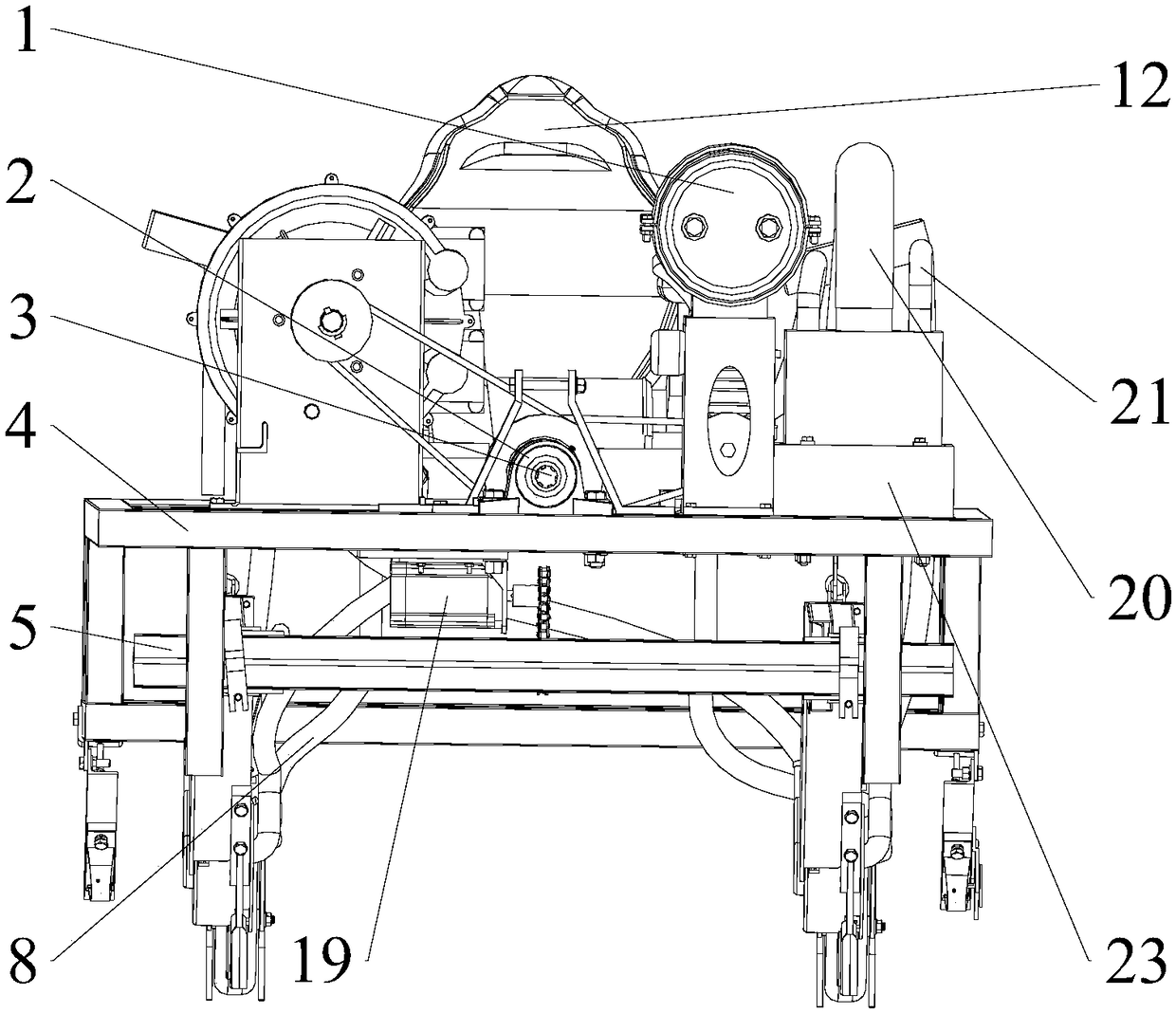

[0042] 1) Drive the tractor, transmit power through the power input shaft 3 to make the seeder enter the normal working state, and drive the vacuum blower 16 and the air pump 1 to work.

[0043] 2) Start the solenoid valve control switch to make the vacuum blower 16 and the seed meter 26 form a vacuum under the connection of the three-way body 22 and the air guide pipe 15 to provide the seed meter 26 with suction power.

[0044] 3) The seed metering device 26 moves the seeds adsorbed on the forced seed metering disc 31 under the drive of the seed metering disc drive motor 19, and discharges them into the ditch as the forced seed metering disc 31 rotates.

[0045] 4) When seeding, the encoder 11 fixed on the ground wheel collects the rotation speed of the ground wheel 10, converts the data through the internal converter and transmits it to the seeding disc drive motor 19 to control the seeding speed, so that the seeder can com...

Embodiment 2

[0047] 1) The steps of community clearing are as follows:

[0048] 2) After the sowing of the plot is finished, the tractor stops moving forward but the power input shaft 3 still rotates. This rotation still provides power to vacuum blower 16, makes it produce vacuum degree. The switching device 71 is switched to the clearing direction, and the waste seed recovery chamber 23 is connected with the vacuum blower 26; the vacuum degree of the waste seed recovery chamber 23 is transferred to the seed storage housing 7 through the seed clearing pipe 21; Under the action, be sucked back to waste seed recovery chamber 23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com