Defect detection equipment for production line

A defect detection and equipment technology, applied in sorting and other directions, can solve problems such as increasing production costs and reducing product yield, and achieve the effects of improving pass rate, reducing costs, and saving testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

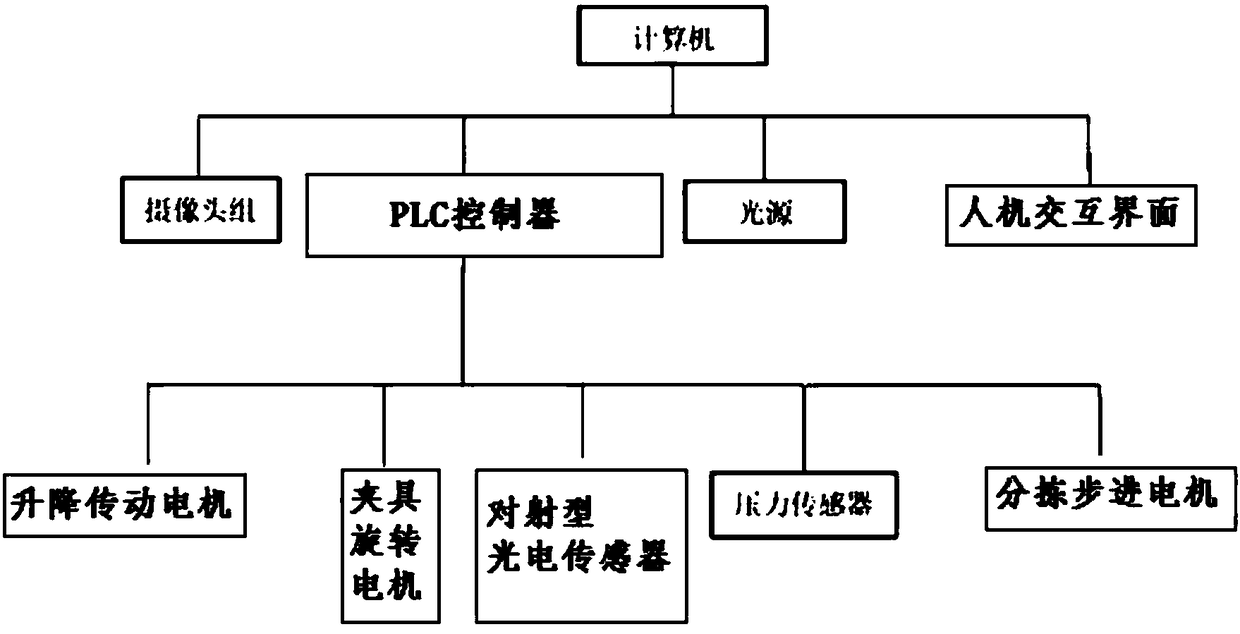

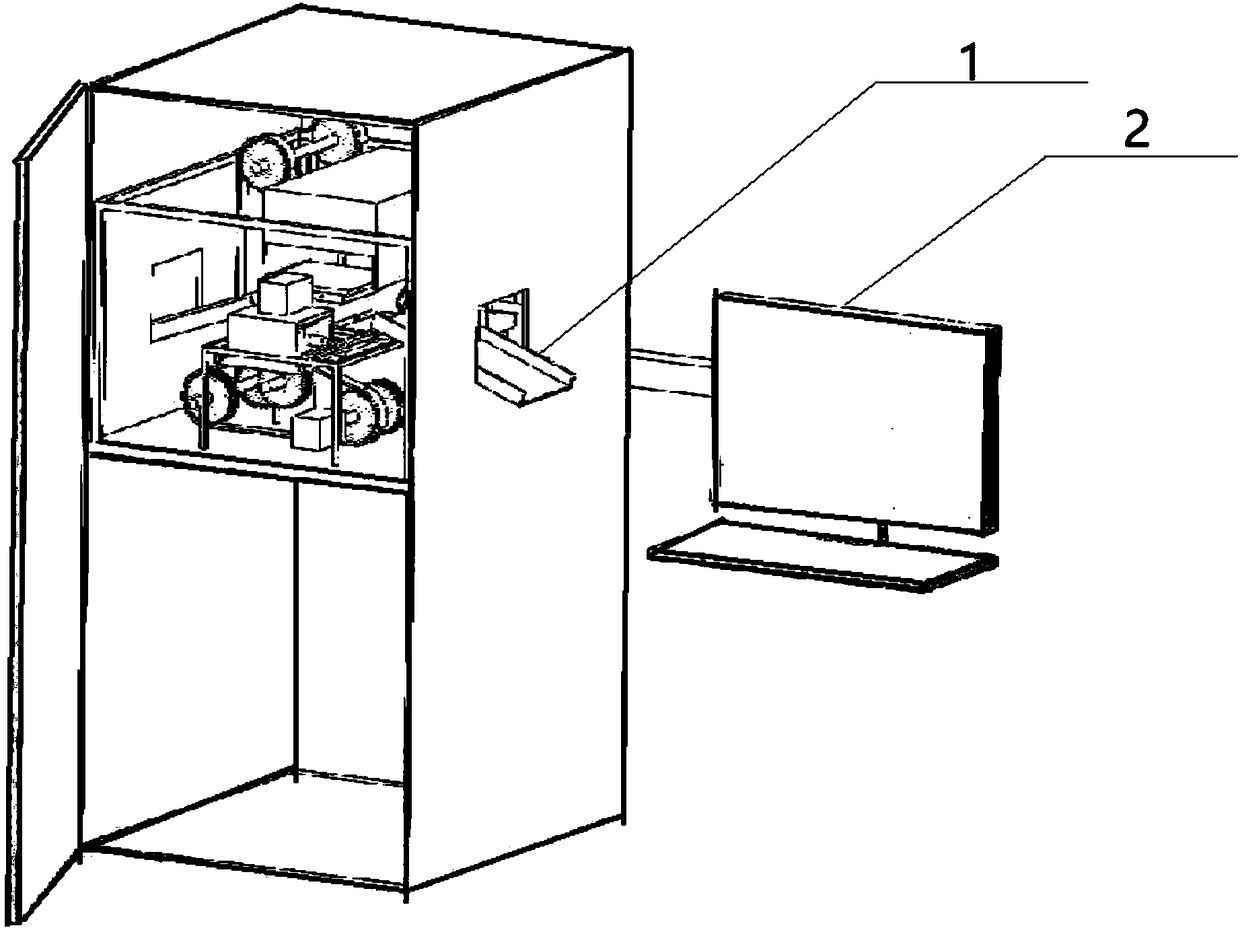

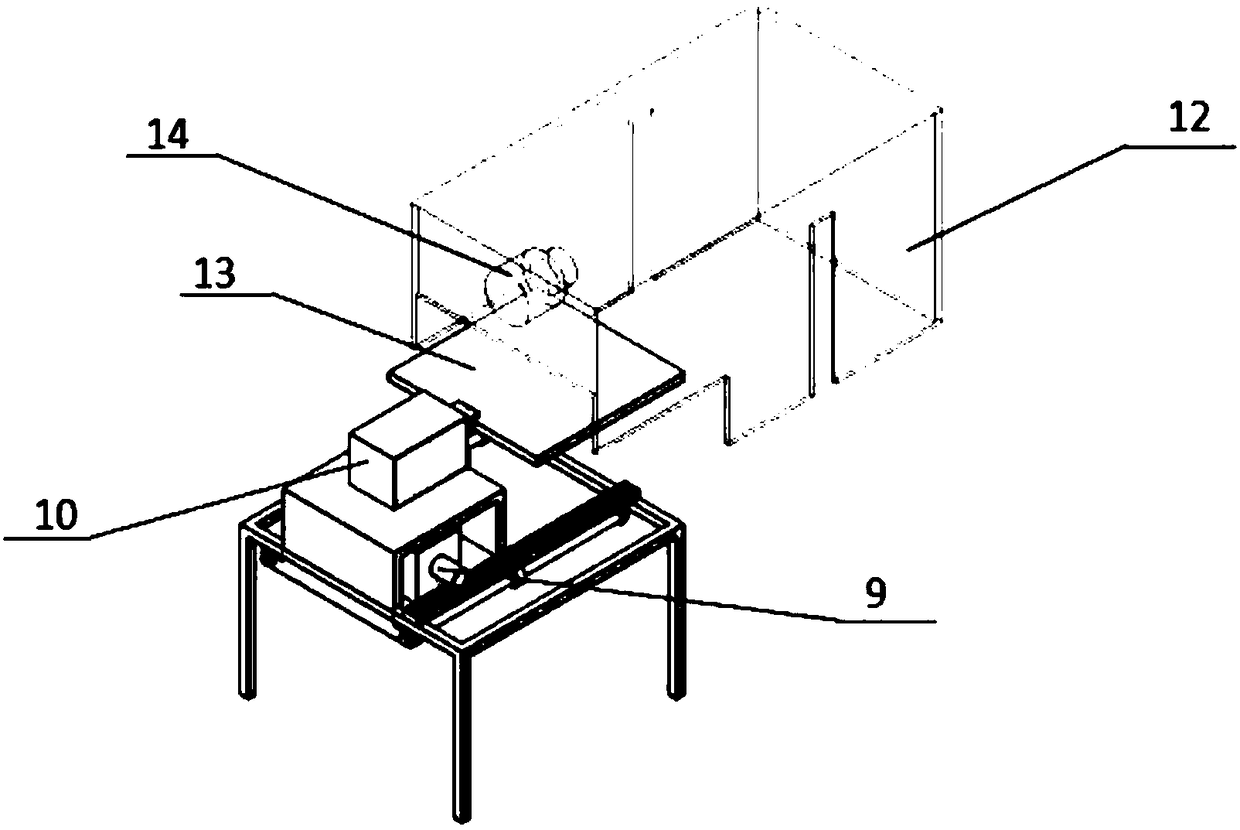

[0030] like Figure 1-Figure 4 As shown, a defect detection device used on a production line includes a delivery part, a detection part, a sorting part, a computer and a PLC controller. The specific model of the PLC controller is XINJEXC5-32T-C.

[0031] In order to prevent moisture and achieve a better connection with the factory assembly line, the detection equipment is placed in the cabinet for lifting, and the upper part of the cabinet is the hardware structure.

[0032] The feeding part includes a feeding detection unit and a gripper unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com