Adjustable positioning clamping mechanical hand

A technology of positioning clamping and manipulators, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of small clamping force, unsuitable for grasping test equipment, complex structure of clamping manipulators, etc., and achieve large clamping force , the effect of streamlining the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

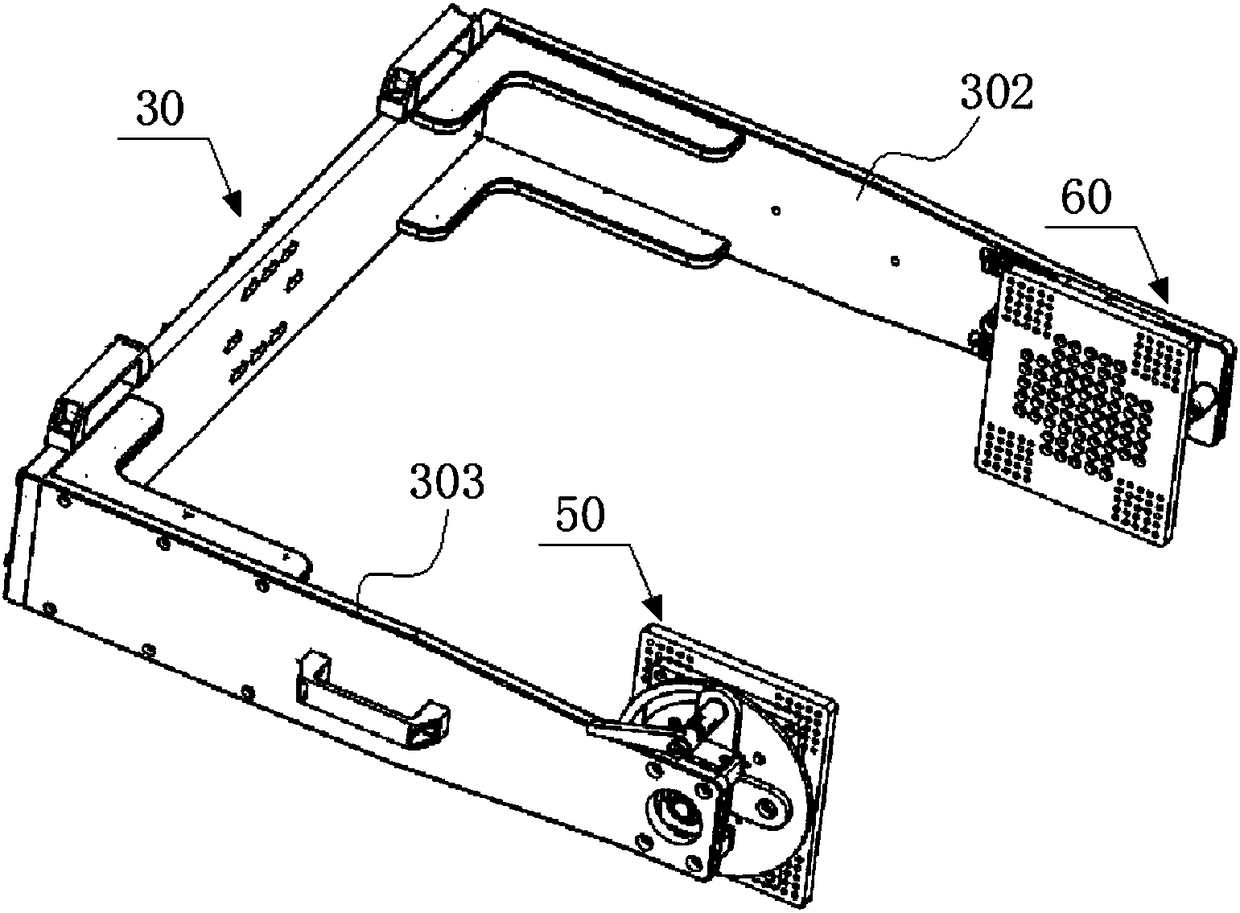

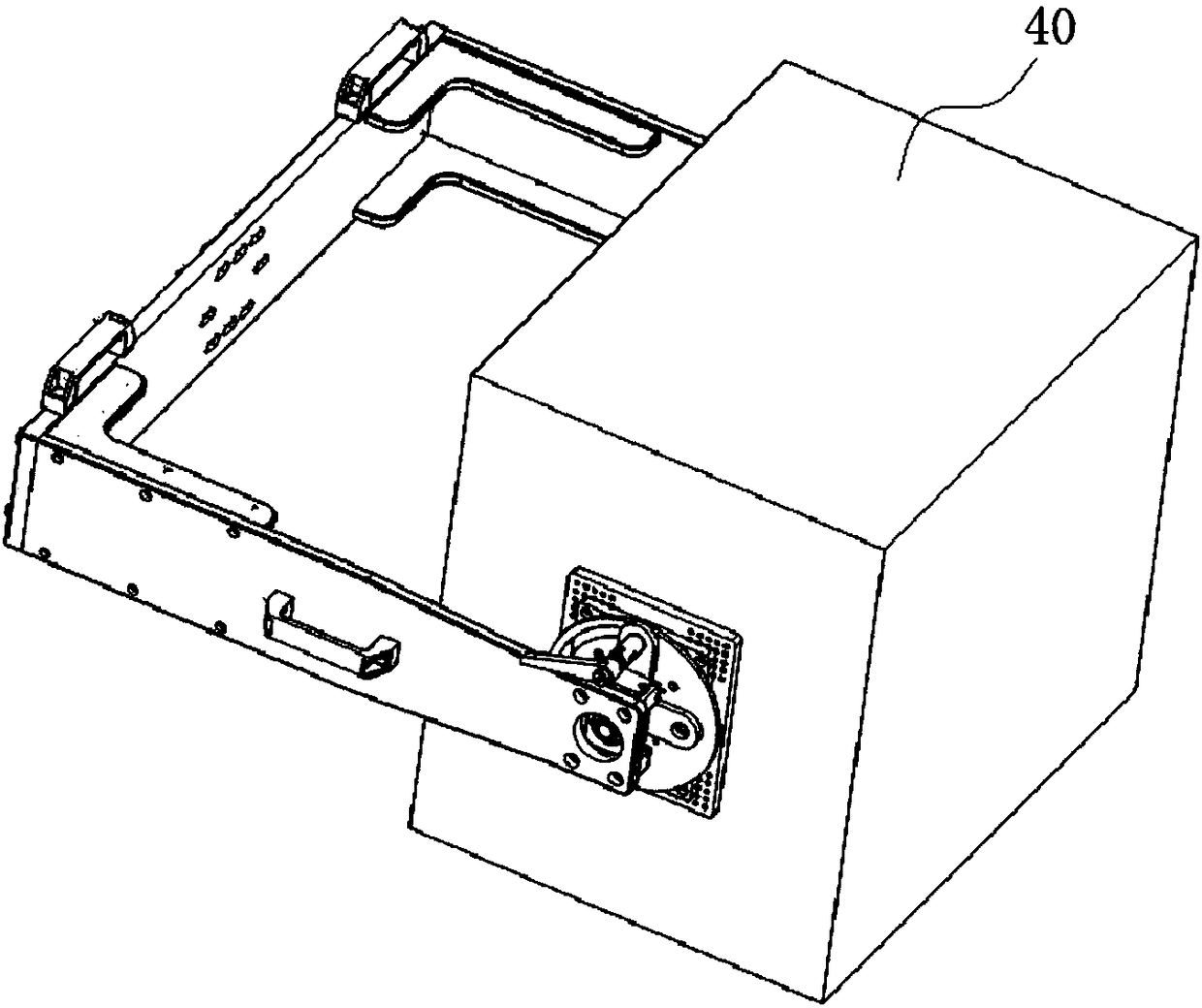

[0039] Example: An adjustable positioning and clamping manipulator, such as Figure 1 to Figure 9 As shown, a clamping arm 30 is included. The arms of the clamping arm include a left arm 302 and a right arm 303 that can clamp the device 40 to be clamped. The left arm and the right arm are parallel to each other, defining all The opening of the clamping arm is the front, and the side close to the device is the inside. One of the front end of the left arm and the front end of the right arm is provided with a first clamping mechanism 50, and the other has The second clamping mechanism 60 can fix the device to be clamped through the first clamping mechanism and the second clamping mechanism;

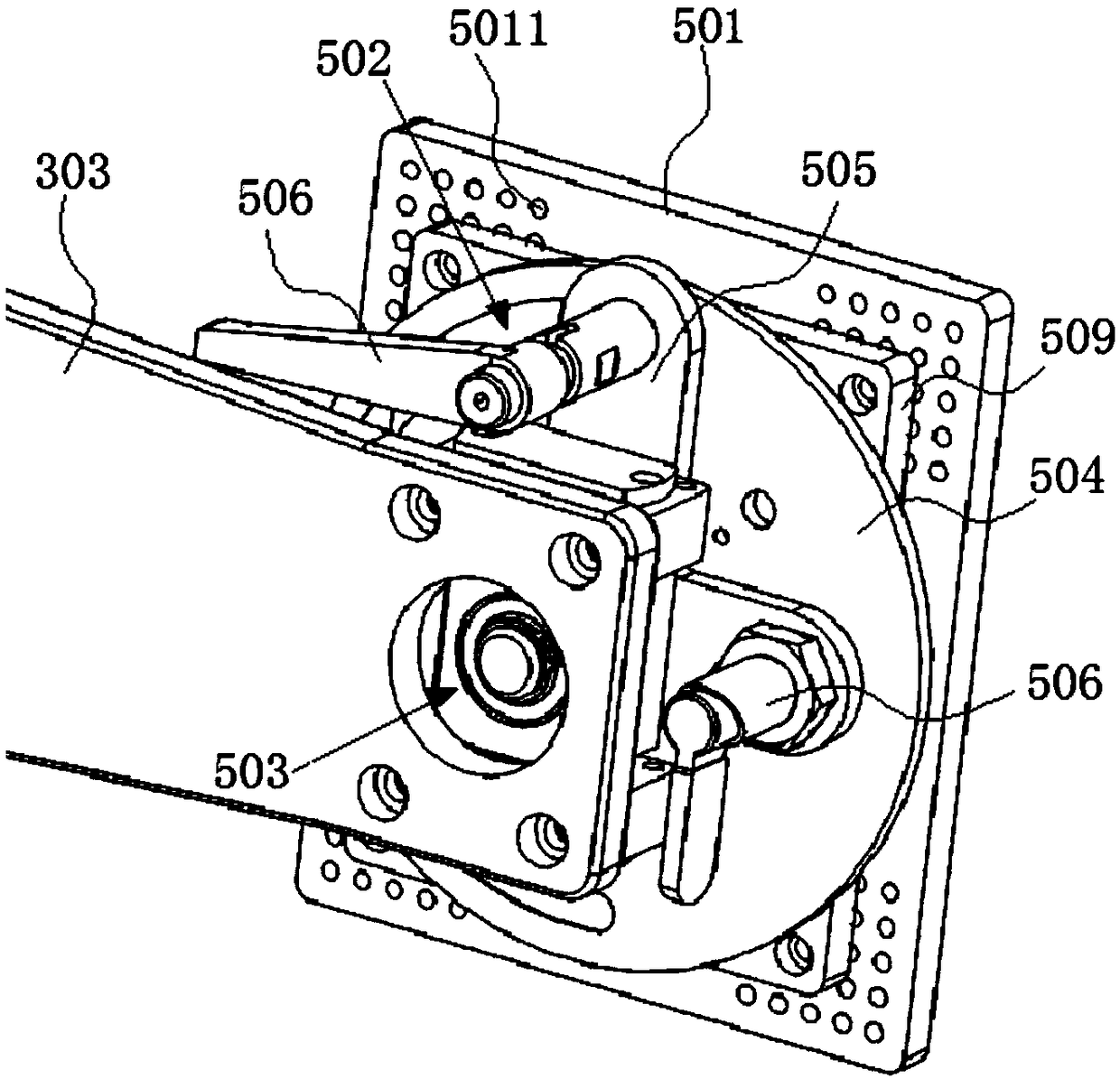

[0040] Such as image 3 As shown, the first clamping mechanism includes a first mounting plate 501, a rotating structure 502 capable of driving the first mounting plate to rotate in a vertical plane, and a rotating structure 502 capable of driving the first mounting plate to swing in a vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com