Prefabricated laminated slab combination stacking transport frame

A transport frame, laminated board technology, applied in the directions of transport and packaging, containers, containers to prevent mechanical damage, etc., can solve the problems of no size and style of prefabricated components, falling transport frame components, unbalanced transport frames, etc., to achieve structural The effect of simplicity, improved stability, and improved transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

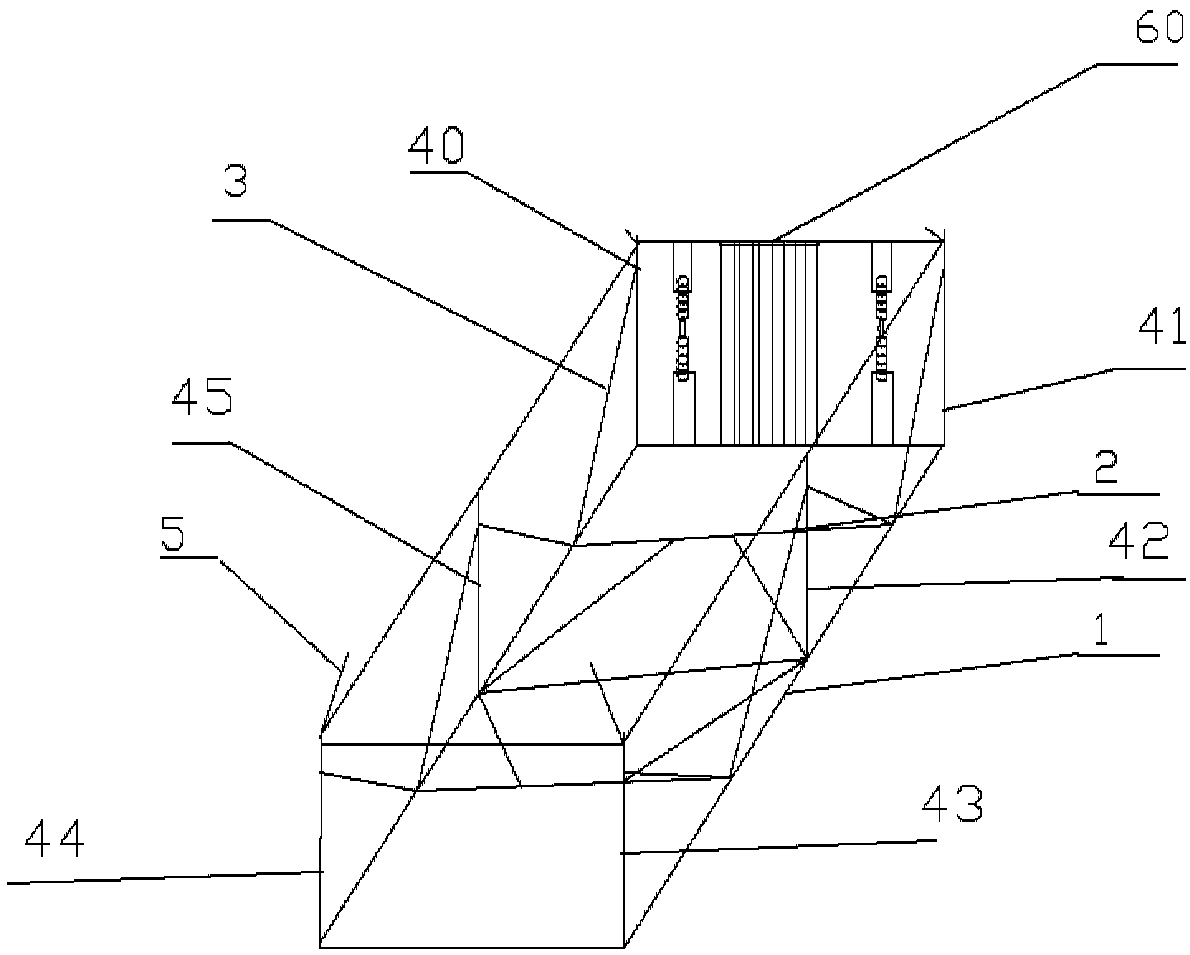

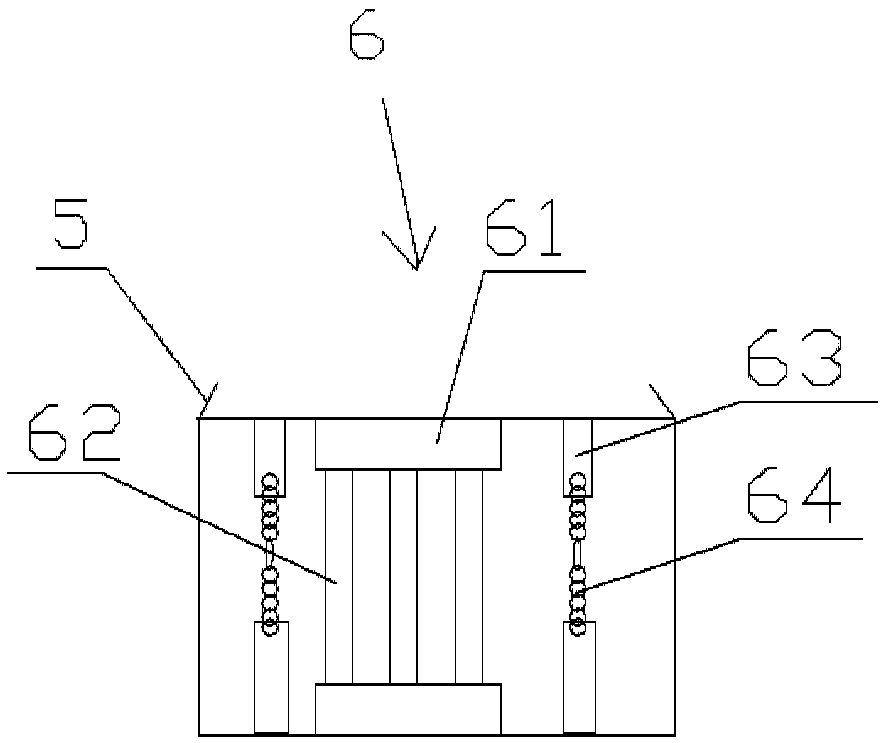

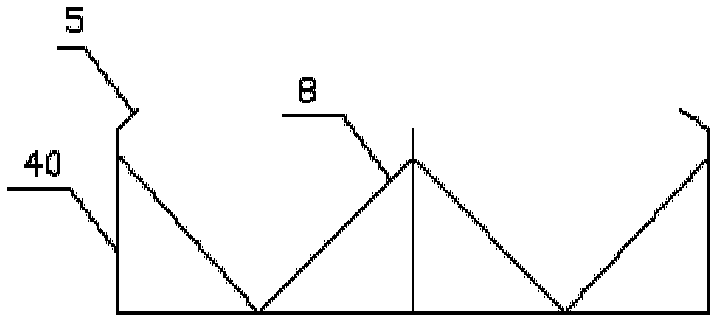

[0040] In an exemplary embodiment of the present disclosure, there is provided a prefabricated laminated plate combination stacking transport rack, such as figure 1 , figure 2 as well as image 3 As shown, a prefabricated laminated plate combination stacking transport frame is characterized in that the transport frame includes several single frames 1, and the single frame 1 includes a single-layer frame bottom frame 2 and guardrails 3, and the guardrails 3 are arranged vertically and symmetrically. There are support columns, and the support columns include a first support column 40, a second support column 41, a third support column 42, a fourth support column 43, a fifth support column 44, and a sixth support column 45. The second support column Between the column 41, the third support column 42, the fourth support column 43 and between the first support column 40, the fifth support column 44, and the sixth support column 45, a reinforced I-shaped steel plate 8 is arranged,...

specific Embodiment 4

[0075] This embodiment is basically the same as Embodiment 1, the difference is that: the material of the guide brace 5 is steel, the guide brace 5 is channel steel, the frame of the bottom frame 2 of the single-layer frame is channel steel, and the guide The angle between the diagonal brace 5 and the horizontal plane is 60-75 degrees, preferably 70 degrees. The material cost of such a design is low, the strength is good, and it is easy to process, and it has high technical requirements for the crane driver.

specific Embodiment 5

[0076] This embodiment is basically the same as Embodiment 1, the difference is that: the material of the guide brace 5 is steel, the guide brace 5 is cylindrical, the frame of the single-layer frame bottom frame 2 is channel steel, and the single-layer frame bottom frame 2 is made of channel steel. The bottom edge of the bottom frame of the floor frame 2 is rounded, and the angle between the guide brace 5 and the horizontal plane is 45-75 degrees, preferably 50 degrees. The material cost of such a design is low, and the requirements for the technical level of the crane driver are moderate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com