Mounting structure for wall-to-wall connection and its assembly and disassembly methods

An installation structure and hinged technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of large number of vertical connection surfaces, long construction period, and large engineering volume, so as to improve installation efficiency, improve connection strength, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

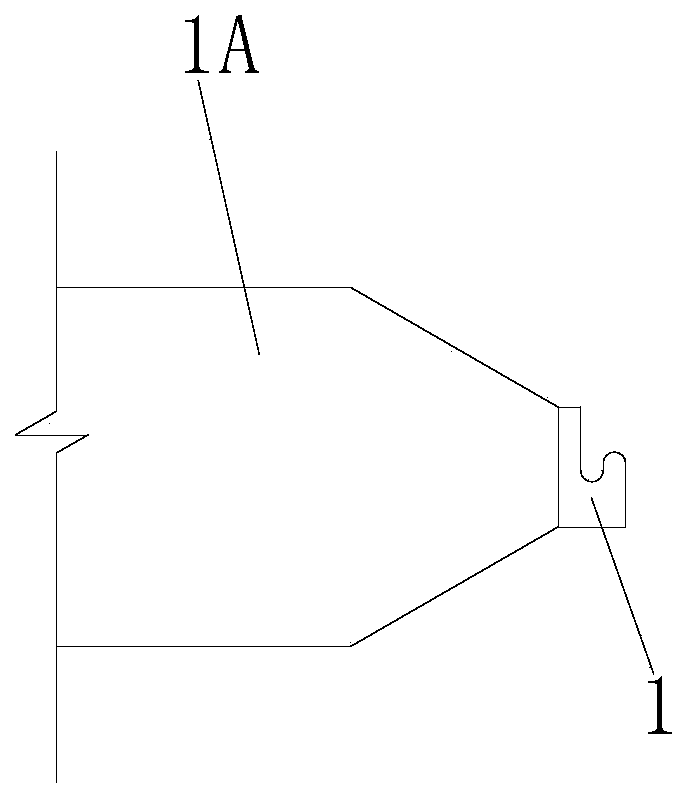

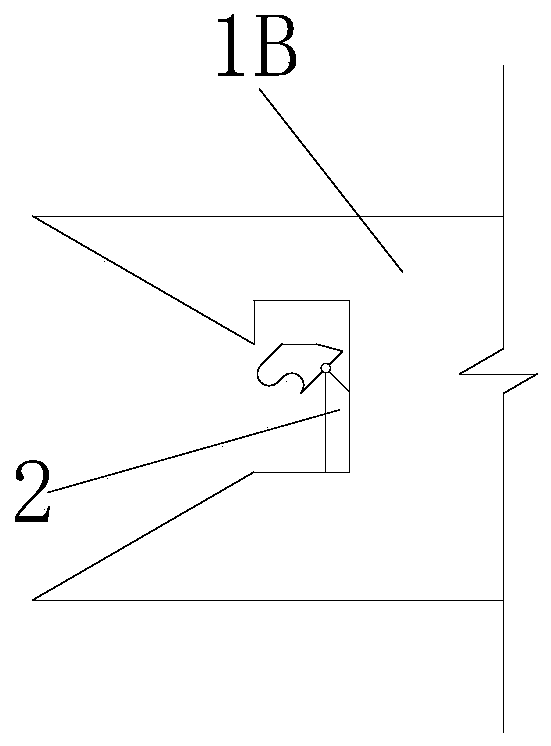

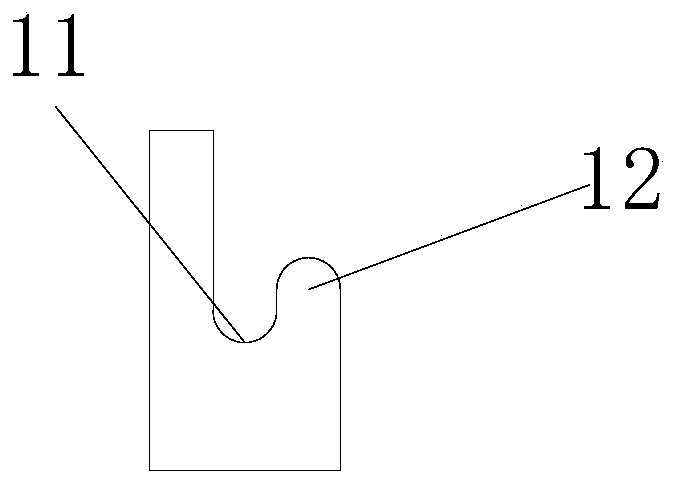

[0041] Such as figure 1 and figure 2 As shown, an installation structure for wall-to-wall connection includes a concave wall with a tenon on one side and a convex wall with a tenon that can be engaged with the tenon on one side; the tenon and tenon They are all vertically arranged; on the side of the tenon relative to the tenon groove, there are several fixed clips with slots at intervals along the vertical direction; corresponding movable clips are provided in the mortise corresponding to each fixed clip ;Such as Figure 4As shown, the movable clamping piece includes a movable clamping block and a support fixed in the mortise. The movable clamping block is hinged on the support and can rotate horizontally around the hinge point. One end of the movable clamping block is provided with a The clip in the draw-in slot of the fixed clip; also includes the clip that can keep the clip of the movable clip facing the draw-in slot of the fixed clip and makes the hinged side of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com