Integrated vibration damping belt pulley characteristic tester

A characteristic test, pulley technology, applied in measuring devices, machine gear/transmission mechanism testing, instruments, etc., can solve problems such as hydraulic servo system non-compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

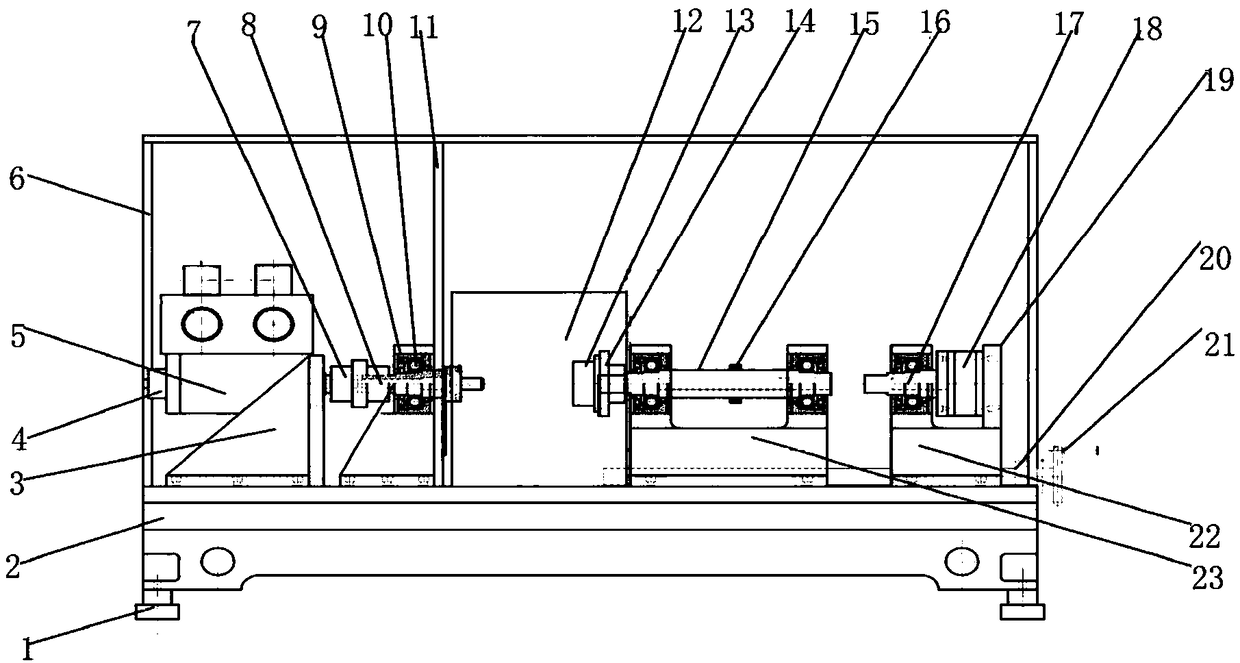

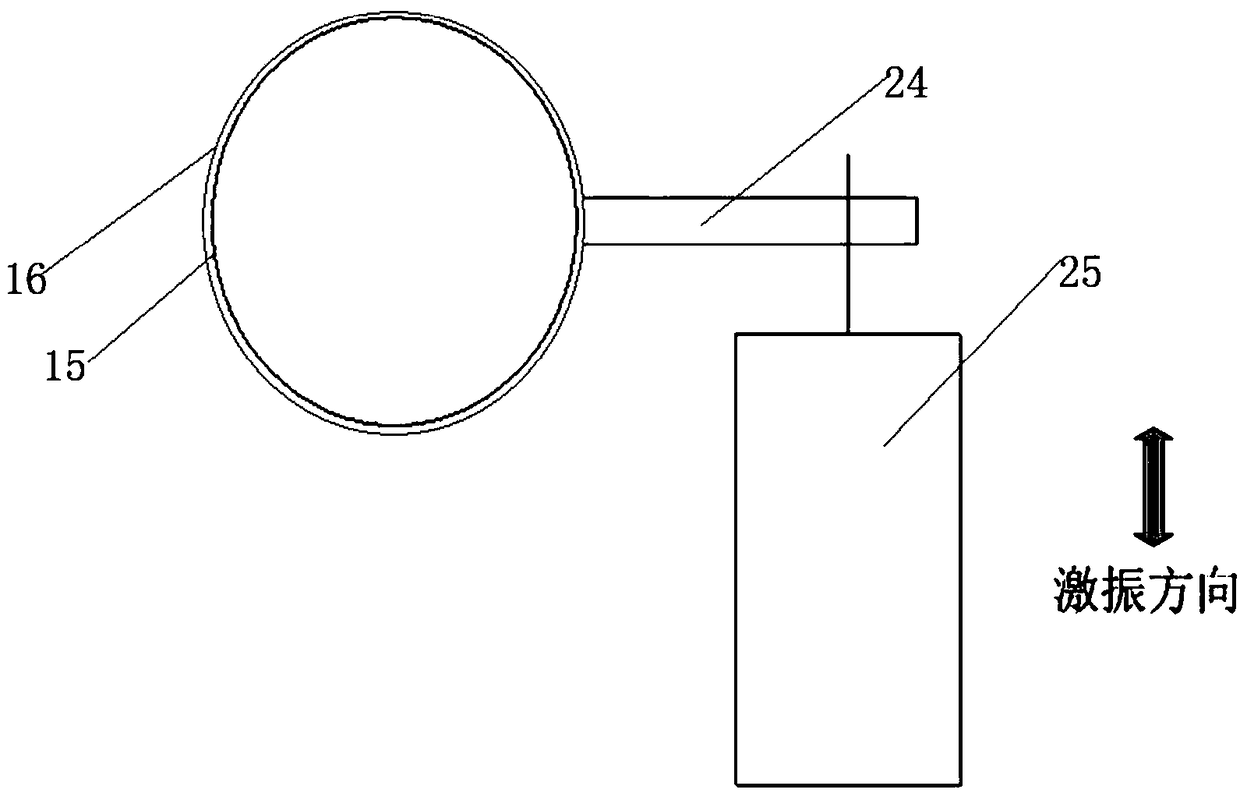

[0025] Such as figure 1 As shown, an integrated vibration-absorbing pulley 13 characteristic test device includes a test bench, a servo oil station, sensing parts, auxiliary parts and an industrial control cabinet, such as figure 2 As shown, the base 2 of the test bench is provided with an environmental chamber 12, a slide rail and a vibrator 25. The environmental chamber 12 can be set at different temperatures and kept warm. Sliding table 3, durable loading sliding table 22 and natural frequency loading sliding table 23, the servo power sliding table 3 is provided with an actuator whose power is provided by the servo oil station and whose output shaft can be coaxially connected with the inner wheel of the vibration-absorbing pulley 13 5. The durable loading slide 22 is provided with a fixed shaft 17 coaxial with the output shaft of the actuator 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com