High vibrating-intensity performance vibrating machine MCU (microprogrammed control unit) advance control device and control method thereof

A technology of advanced control and vibrating mills, which is applied in other fields, can solve problems such as the impact of the operator's working environment, scrapping, and increased frequency of parts maintenance, achieving good absorption and vibration isolation effects, flexible control structure, and increased calculation frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

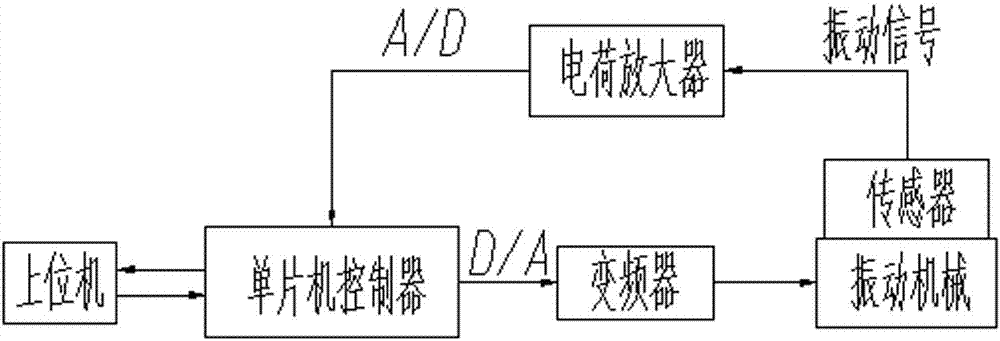

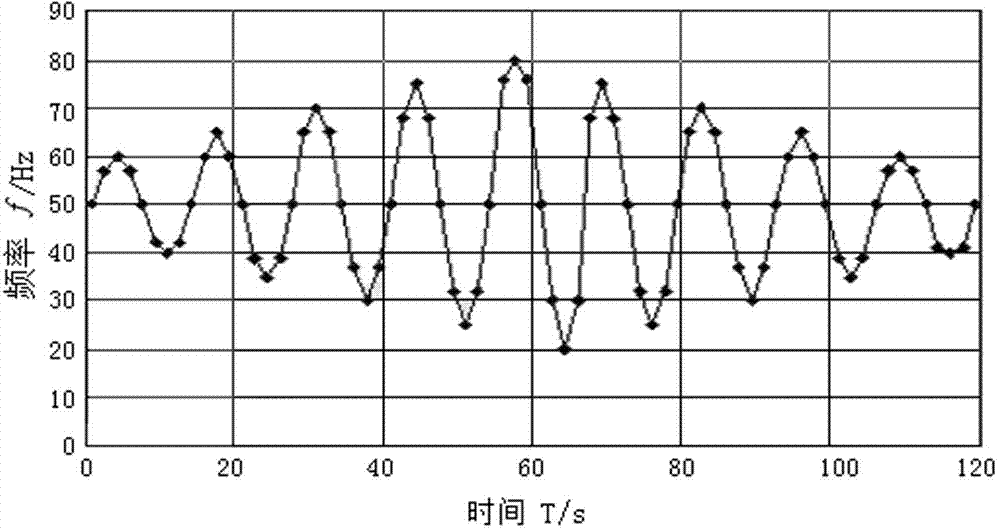

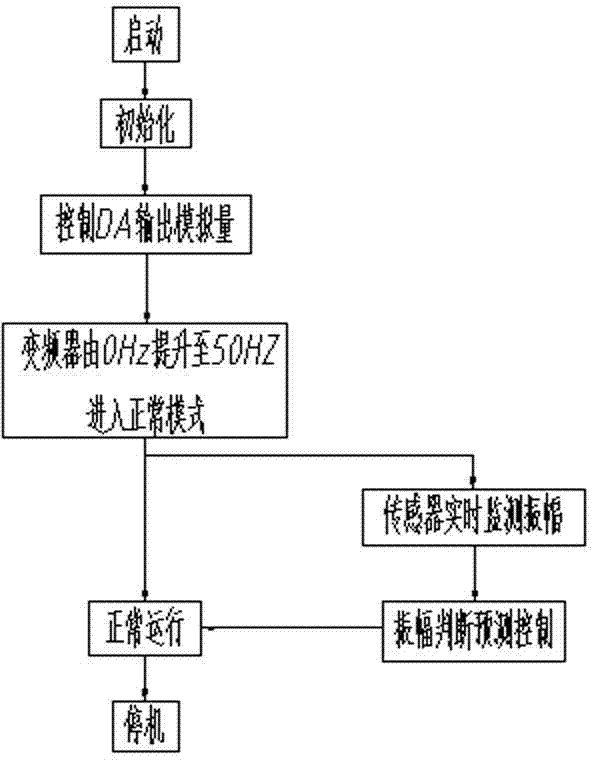

[0040] Refer to attached figure 1 , the MCU intelligent frequency conversion advanced control device with high vibration strength performance of vibration machinery is a closed-loop system composed of upper computer, frequency converter, AVR single-chip microcomputer, charge amplifier, sensor, vibration machinery, etc. At the same time, combined with the use of VB programs to monitor the operation of the single-chip microcomputer in real time; at the same time, the AVR single-chip microcomputer and its peripheral digital-to-analog conversion expansion module and frequency converter are used together to convert the digital quantity into an analog quantity, and then pass the analog quantity through the analog quantity. The output port of the digital conversion module is connected to the 0-5V voltage frequency setting port of the frequency converter, and the frequency conversion control is performed on the frequency converter to realize the variable sine wave cycle output setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com