Plastic cell and method for manufacturing same

A plastic, plastic-based technology, applied in chemical instruments and methods, other household appliances, cellulose plastic layered products, etc., can solve the problem that glass substrates are difficult to meet the requirements of light weight and bendability, and achieve the effect of maintaining electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

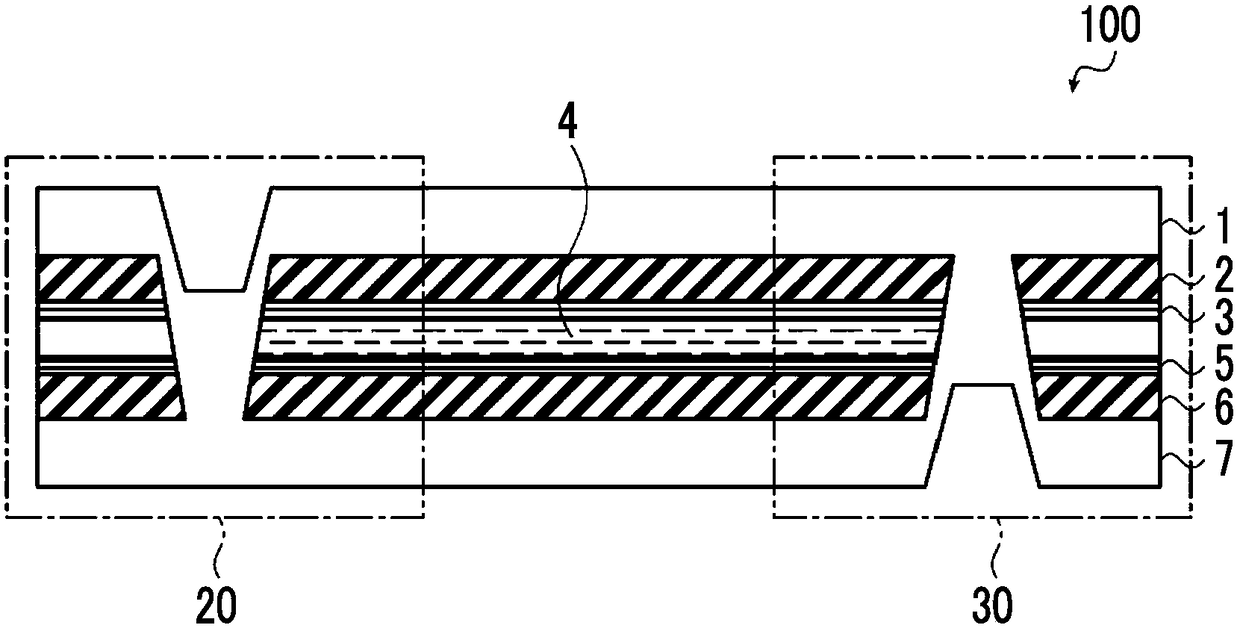

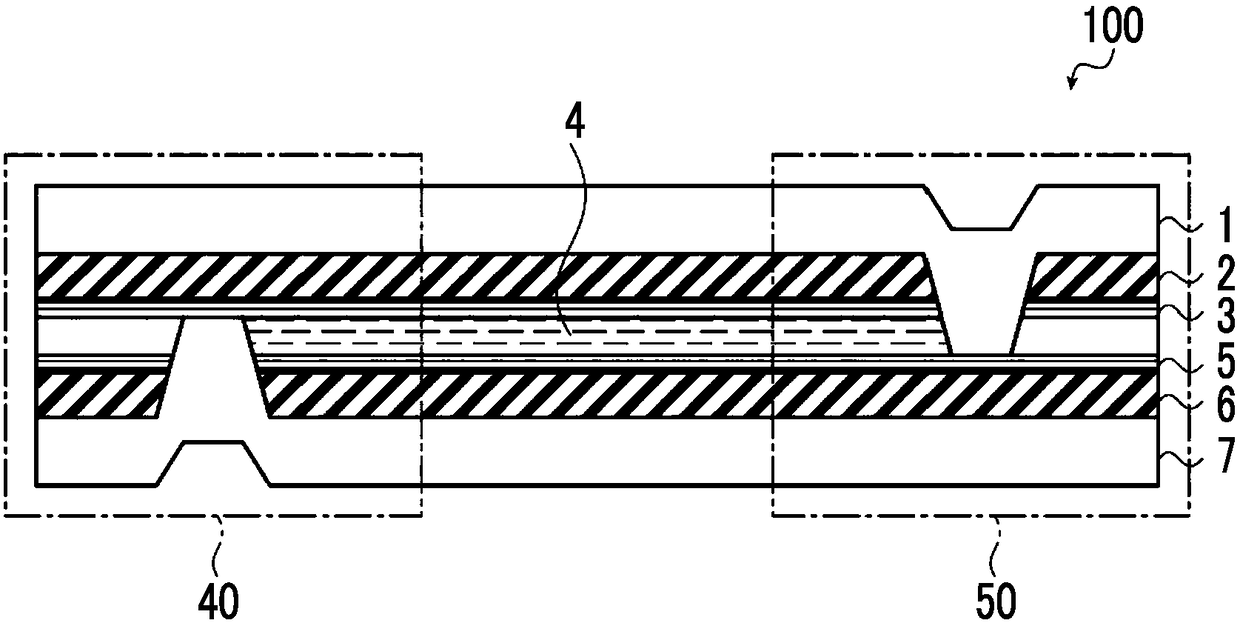

Embodiment 1

[0125]

[0126] By the method described in Example 1 of US2013 / 0341074, Ag nanowires were used to form a transparent conductive layer on the surface of polycarbonate (PC-2151, thickness 250 μm) manufactured by TEIJIN LIMITED. A laminate of an ester plastic substrate and a transparent conductive layer containing Ag nanowires.

[0127]

[0128] The laminated body produced above was cut into 10 cm square, and the polyamic-acid alignment layer coating liquid (JALS684 by JSR Corporation) was applied as a liquid crystal aligning agent using bar coater #1.6.

[0129] Thereafter, the liquid crystal alignment layer 101 was produced by drying at a film surface temperature of 80° C. for 3 minutes. At this time, the film thickness of the liquid crystal alignment layer was 60 nm.

[0130] Two sets of laminates in which the plastic substrate, the transparent conductive layer, and the liquid crystal alignment layer were laminated in this order prepared in this way were prepared.

[013...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com