Photosensitive resin composition, dry film and printed wiring board

A technology of photosensitive resin and composition, applied in the directions of printed circuit, printed circuit manufacturing, optics, etc., to achieve the effect of excellent insulation reliability and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

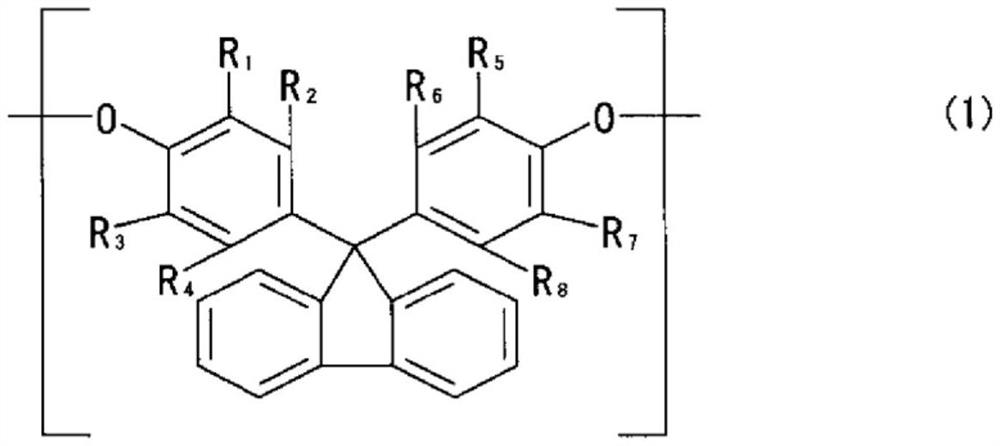

[0170] [Synthesis of carboxyl group-containing resin]

[0171] Synthesis Example A-1 to Synthesis Example A-4 and Synthesis Example B-1 to Synthesis Example B-3

[0172] Into a four-necked flask equipped with a reflux cooler, a thermometer, an air blowing tube, and a stirrer, the raw material components shown in the "First Reaction" column in Table 1 were charged, and they were stirred under air bubbling, thereby preparing a mixture . This mixture was heated in a four-necked flask at the reaction temperature and reaction time shown in the "Reaction Conditions" column of the "First Reaction" column while stirring under air bubbling. Thus, a solution of the intermediate was prepared.

[0173] Next, drop the raw material components shown in the "Second Reaction" column of Table 1 into the solution of the intermediate in the four-necked flask, and stir the solution in the four-necked flask while stirring the solution in the four-necked flask under air bubbling. Heating was carr...

Embodiment 1~32、44 and comparative example 1~9

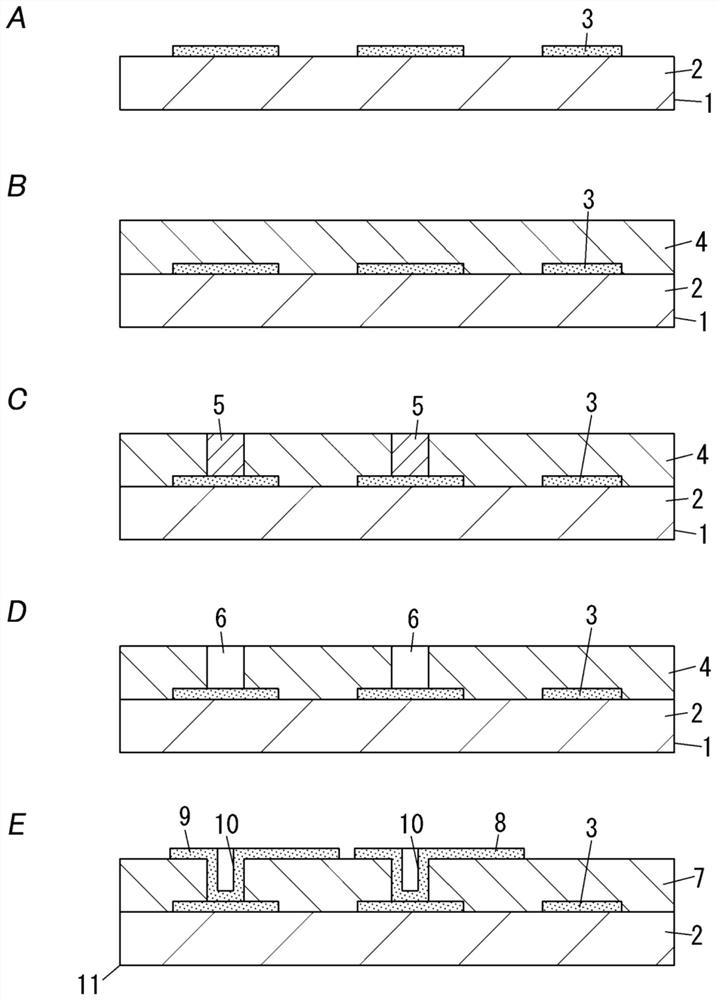

[0228] Examples 1-32, 44 and Comparative Examples 1-9 used the dry film as follows and produced the test piece by the dry film method.

[0229]A glass epoxy copper-clad laminate (FR-4 type) provided with a copper foil having a thickness of 17.5 μm was prepared. A printed wiring board (core material) was obtained by forming comb-shaped electrodes as conductor wiring on the glass epoxy copper-clad laminate by a subtractive method, the comb-shaped electrodes having a line width / space width of 50 μm / 50 μm. The conductor wiring of the printed wiring board was roughened by dissolving and removing the surface portion of the conductor wiring having a thickness of about 1 μm with an etchant (organic acid microetching agent manufactured by MEC Corporation, product number CZ-8100). The above-mentioned dry film was heated and laminated on the entire surface of one surface of the printed wiring board using a vacuum laminator. The conditions for heat lamination were 0.5 MPa, 80° C., and 1 ...

Embodiment 33~43、45、46

[0230]

[0231] About Examples 33-43, 45, 46 and Comparative Examples 10-14, the test piece was produced by the coating method using the photosensitive resin composition as follows.

[0232] A glass epoxy copper-clad laminate (FR-4 type) provided with a copper foil having a thickness of 17.5 μm was prepared. On this glass epoxy copper-clad laminate, comb-shaped electrodes having a line width / space width of 50 μm / 50 μm were formed as conductor wiring by a subtractive method to obtain a printed wiring board (core material). The conductor wiring of the printed wiring board was roughened by dissolving and removing the surface portion of the conductor wiring having a thickness of about 1 μm with an etchant (organic acid microetching agent manufactured by MEC Corporation, product number CZ-8100). The photosensitive resin composition was apply|coated to the whole surface of one surface of this printed wiring board by the spin coating method, and the wet coating film was formed. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap