Stator coil, method for manufacturing stator, and dynamo-electric machine

A stator coil and manufacturing method technology, applied in the direction of manufacturing motor generators, prefabricated windings embedded in motors, electrical components, etc., can solve the problems of difficult mechanization, difficult operation mechanization, and difficulty in preventing stator coils from being enlarged, and achieve the goal of preventing large-scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0037] (Structure of rotating electrical machine)

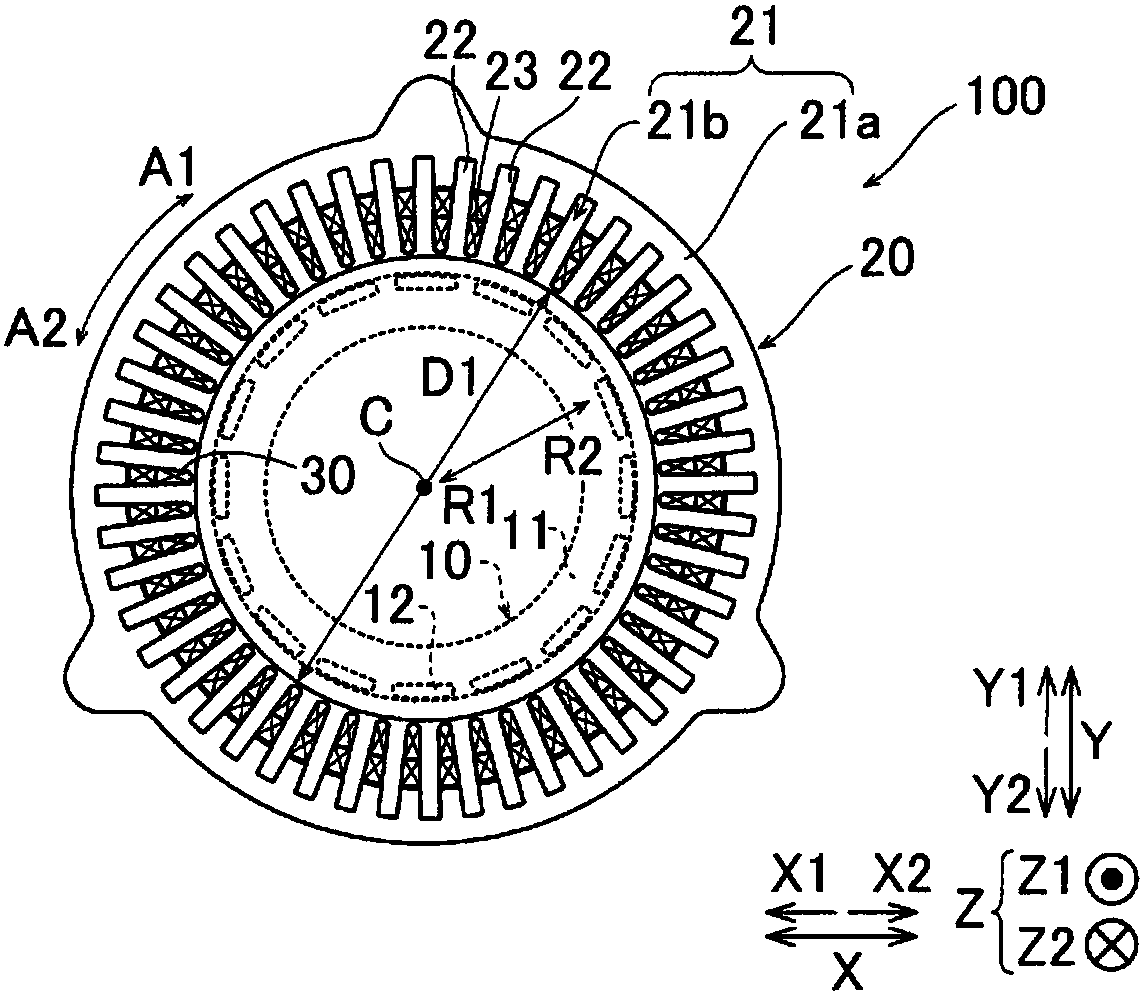

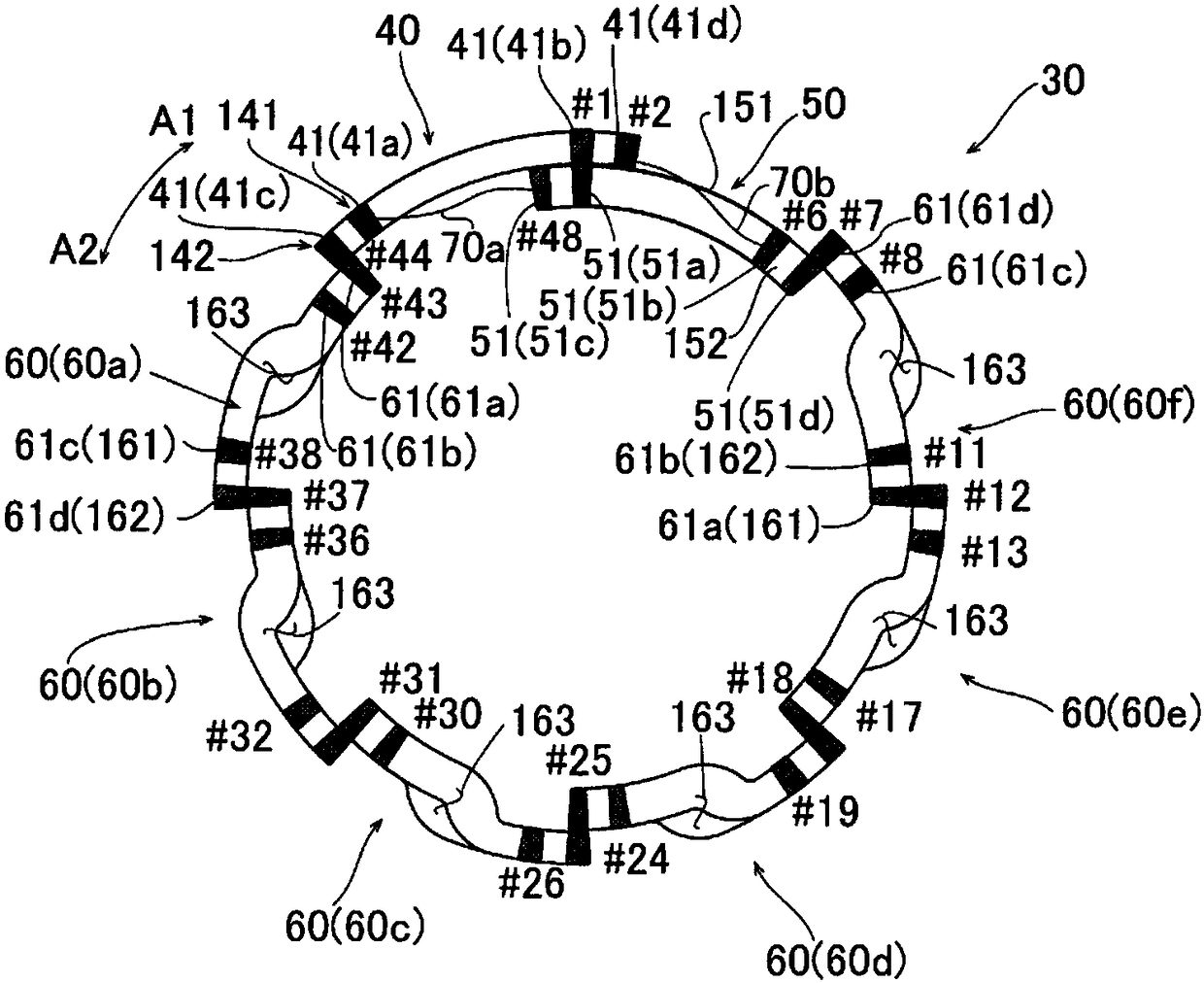

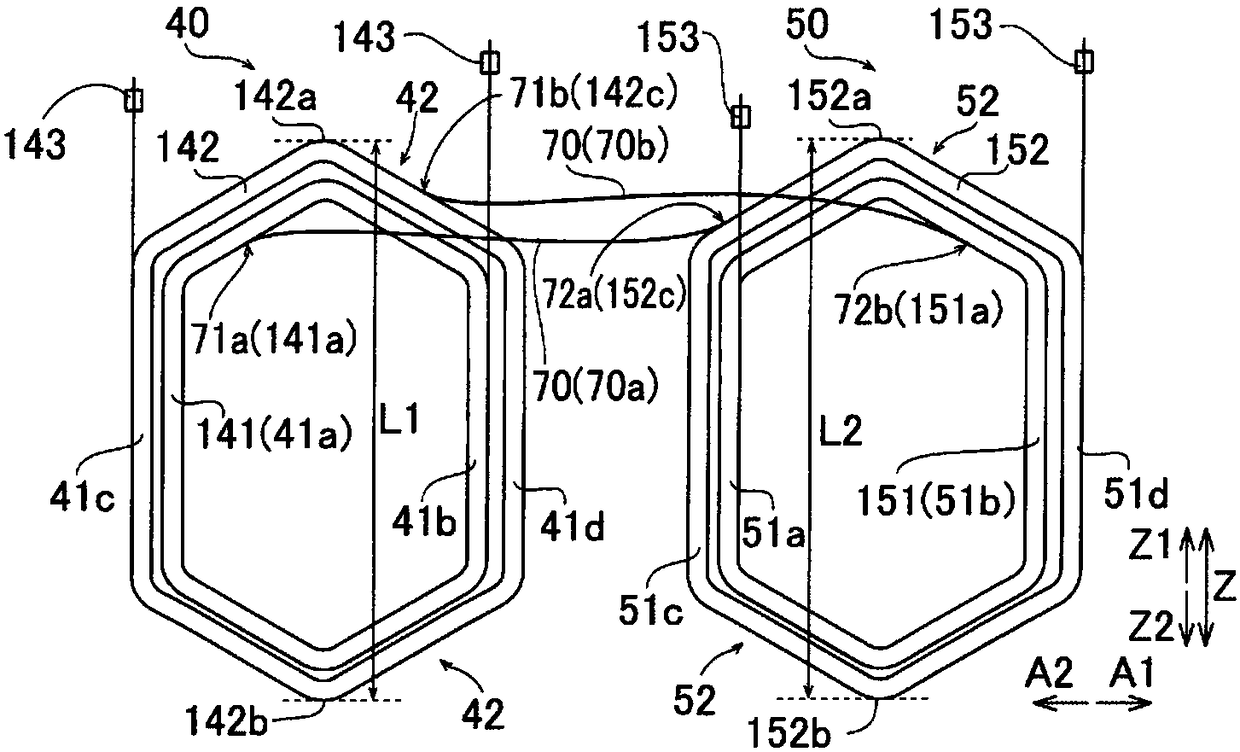

[0038] refer to Figure 1 to Figure 5 , the structure of the rotating electric machine 100 of the first embodiment will be described. figure 1 The illustrated rotating electric machine 100 is, for example, a motor (preferably a three-phase brushless motor). in addition, figure 2 One phase coil 30 of the three phase coils 30 is shown. In addition, the coil 30 is an example of the "stator coil" of a claim.

[0039] In addition, in the present specification, when only "rotation axis direction" or "axial direction" is described, it means the rotation axis direction of the rotary electric machine 100, and means the direction parallel to the Z-axis in the figure. In addition, when only "circumferential direction" is described, it means the circumferential direction of the rotating electric machine 100, and it means the arrow A1 direction or the arrow A2 direction in a figure. When only "radial direction" is described, it refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com