Self-propelled leaf vegetable harvester suitable for ridging type planting and harvesting method

A self-propelled, ridging-type technology, applied in the field of self-propelled leaf vegetable harvesters, can solve the problems that the machine cannot harvest effectively, achieve time-saving and labor-saving harvesting speed, wide application range, and small leaf vegetable offset Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

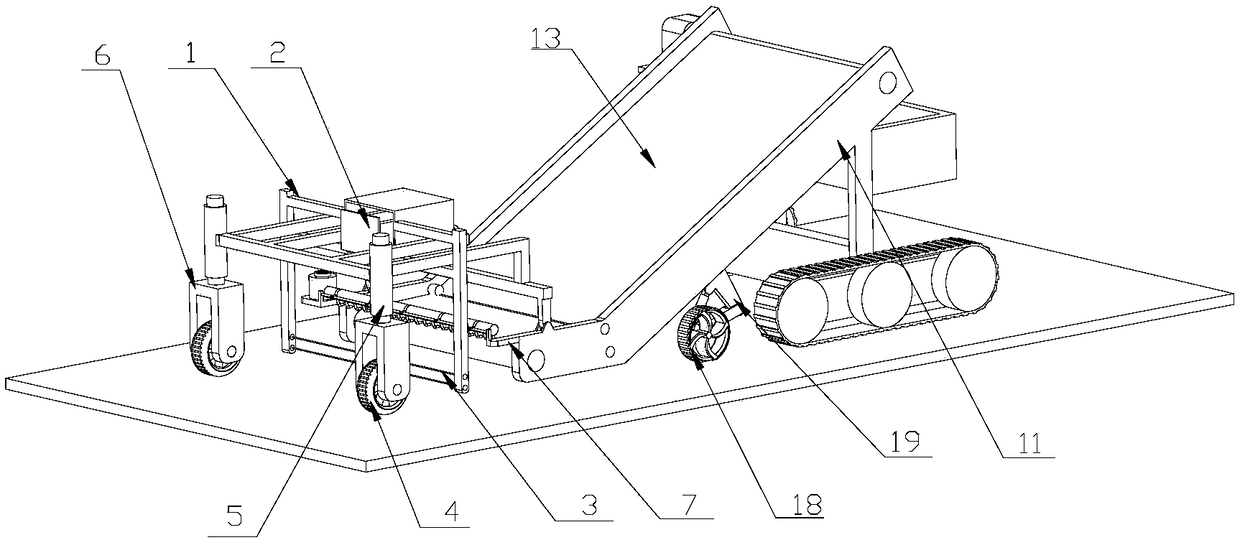

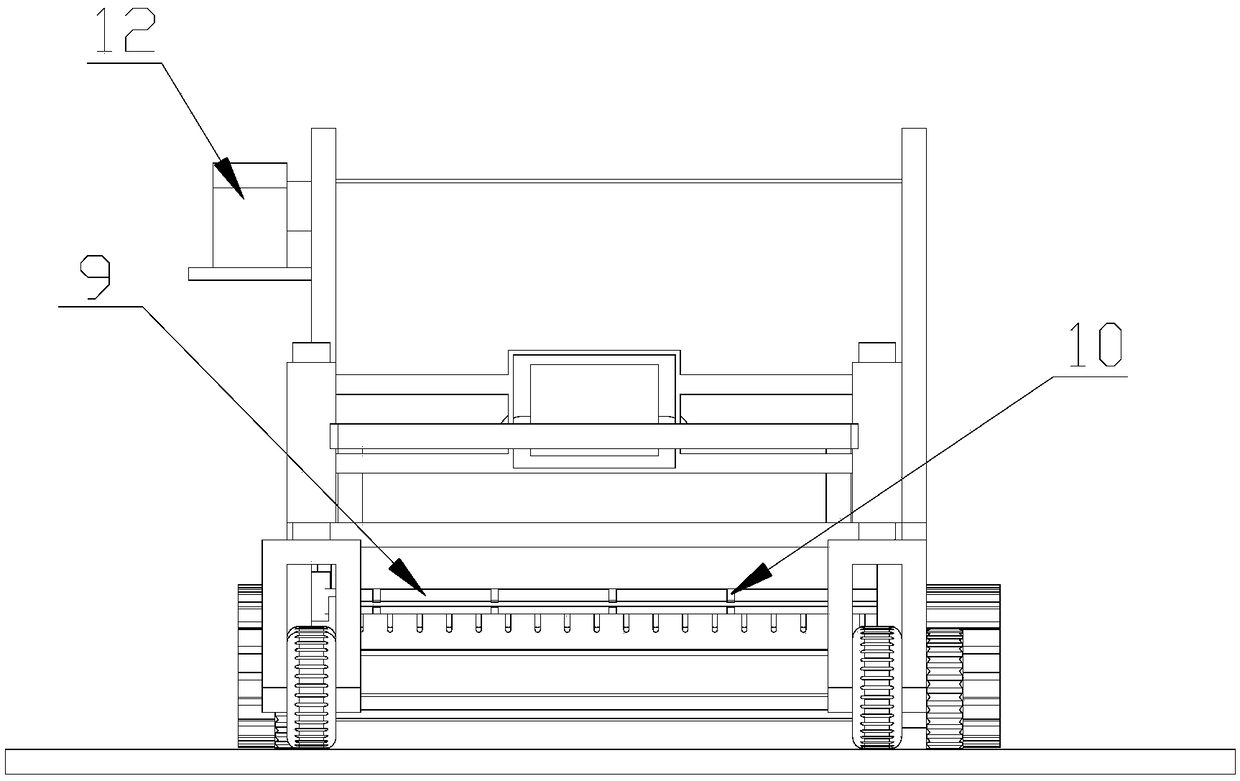

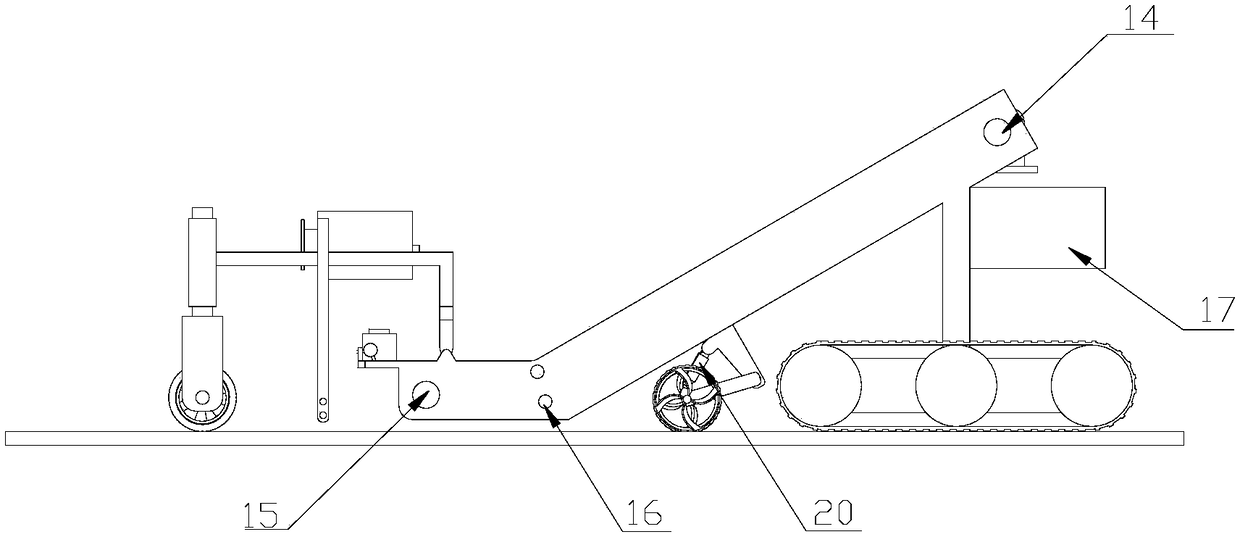

[0026] Below in conjunction with accompanying drawing, the patent of the present invention is further described. Such as figure 1 , 2 , 3, and 4, the vibrating root cutting device includes a vibration root cutting frame 1, a vibration generator 2, a root cutting line 3, a front profiling wheel 4, a spring 5 and a profiling wheel frame 6. Described vibrating root-cutting frame 1 is hingedly connected to delivery device frame 11 horizontal section; Described vibration generator 2 is installed in the middle box of vibration root-cutting frame; The two ends of described root-cutting wire 3 are installed on The vibrating root cutting frame is perpendicular to the bottom of the square tube on the ground; there are two root cutting lines 3, and there is a certain distance between the two root cutting lines 3 in the vertical direction; the front profiling wheel 4 is installed on In the profiling wheel frame 4; the spring 5 is installed in the gap between the upper cylinder of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com