Minced meat processing device

A processing equipment and minced meat technology, applied in the field of minced meat processing equipment, can solve the problems of low work efficiency, inconvenient disassembly and maintenance, complex structure, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

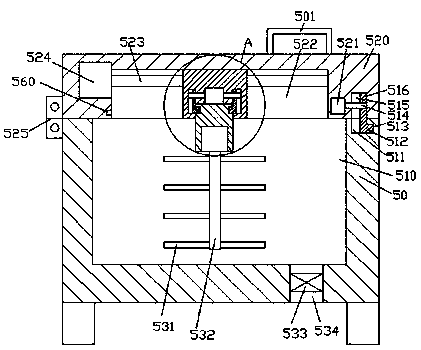

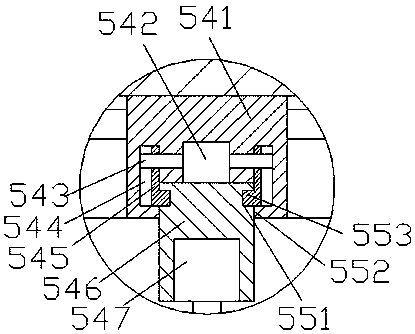

[0013] Combine below Figure 1-Figure 3 The present invention will be described in detail.

[0014] refer to Figure 1-Figure 3 , according to an embodiment of the present invention, a kind of equipment for processing minced meat, comprising a mixing frame body 50 and a panel 520 mounted on the top end surface of the mixing frame body 50 through a hinged shaft 524, the mixing A mixing chamber 510 is arranged in the top end surface of the frame body 50, and a lifting frame 501 is fixedly installed on the right side of the top end surface of the panel 520, and a second mixing chamber 510 opposite to the mixing chamber 510 is arranged in the bottom end surface of the panel 520. A sliding chamber 522, a sliding seat 541 is installed in the first sliding chamber 522, and a first screw rod 523 is installed in the sliding seat 541, and the extended end on the right side of the first screw rod 523 is connected to the The inner wall on the right side of the first sliding chamber 522 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com