Apparel seam adhesive tape plastic-packaging machine

A technology of plastic sealing machine and splicing seam, which is applied in the direction of sewing tools and other directions, can solve the problems of insufficient heat sealing firmness, no sticking, and offset of the rubber strip, so as to achieve uniform width of the plastic sealing strip and prevent hot air burns. , The effect of preventing left and right swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

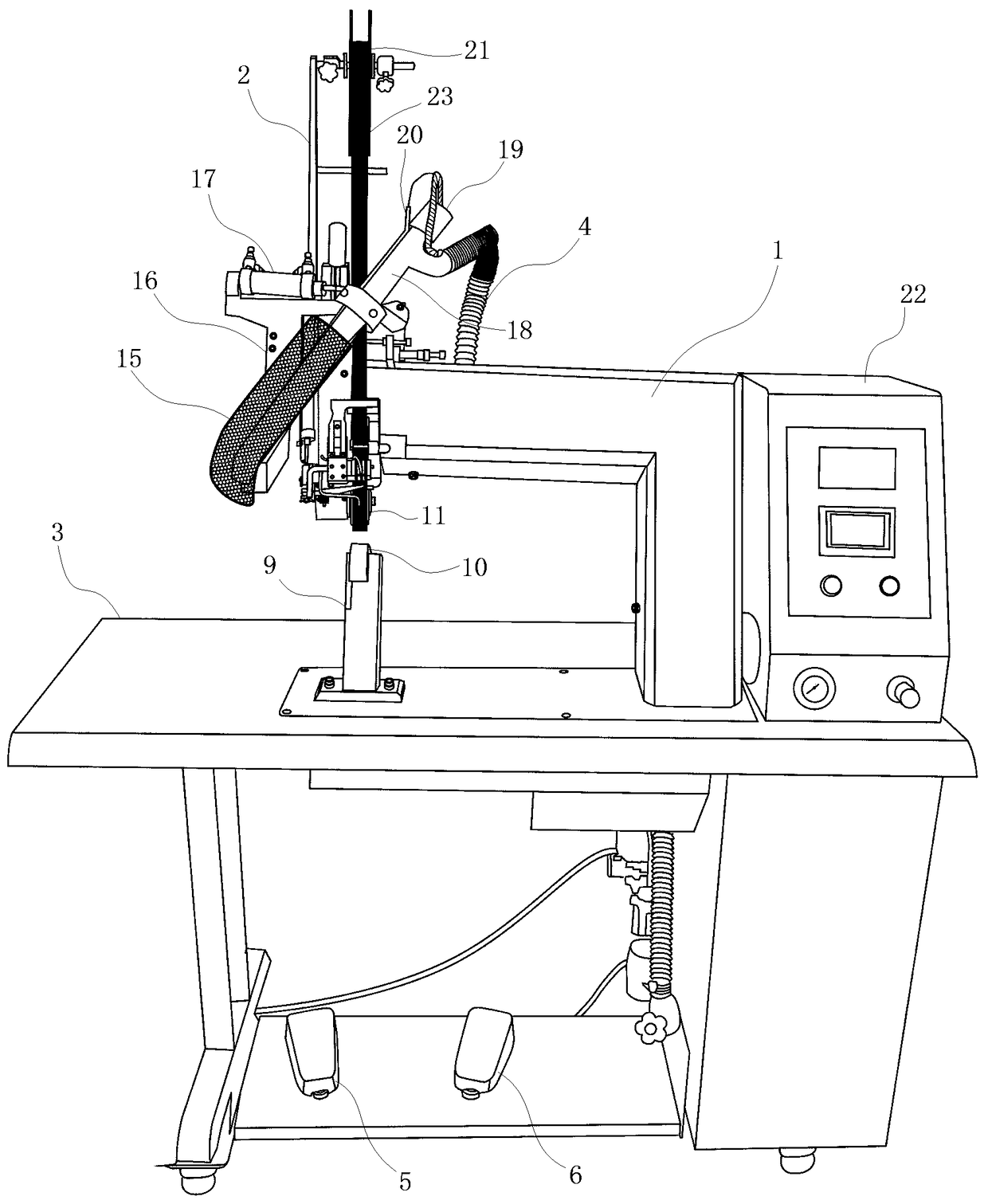

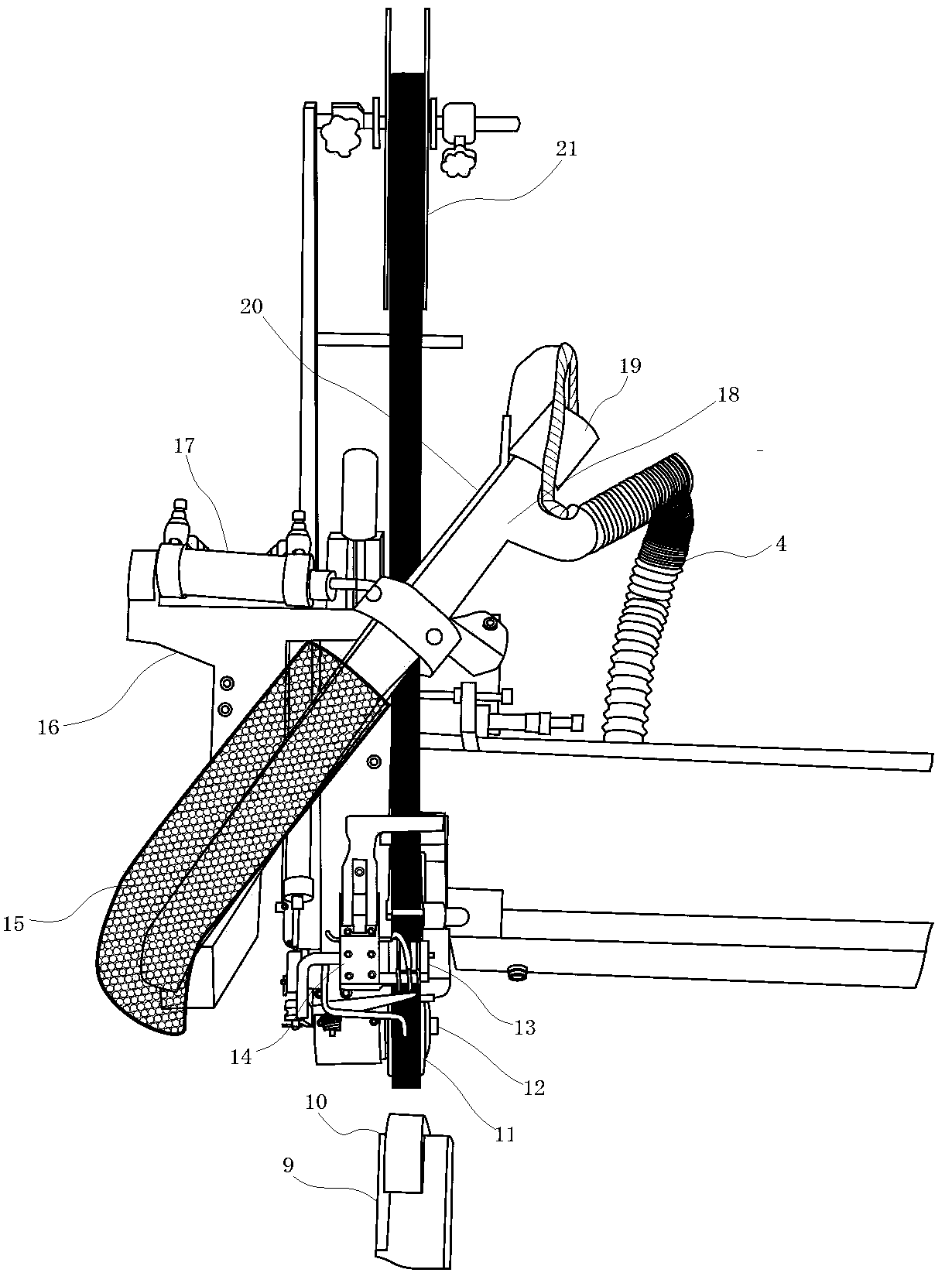

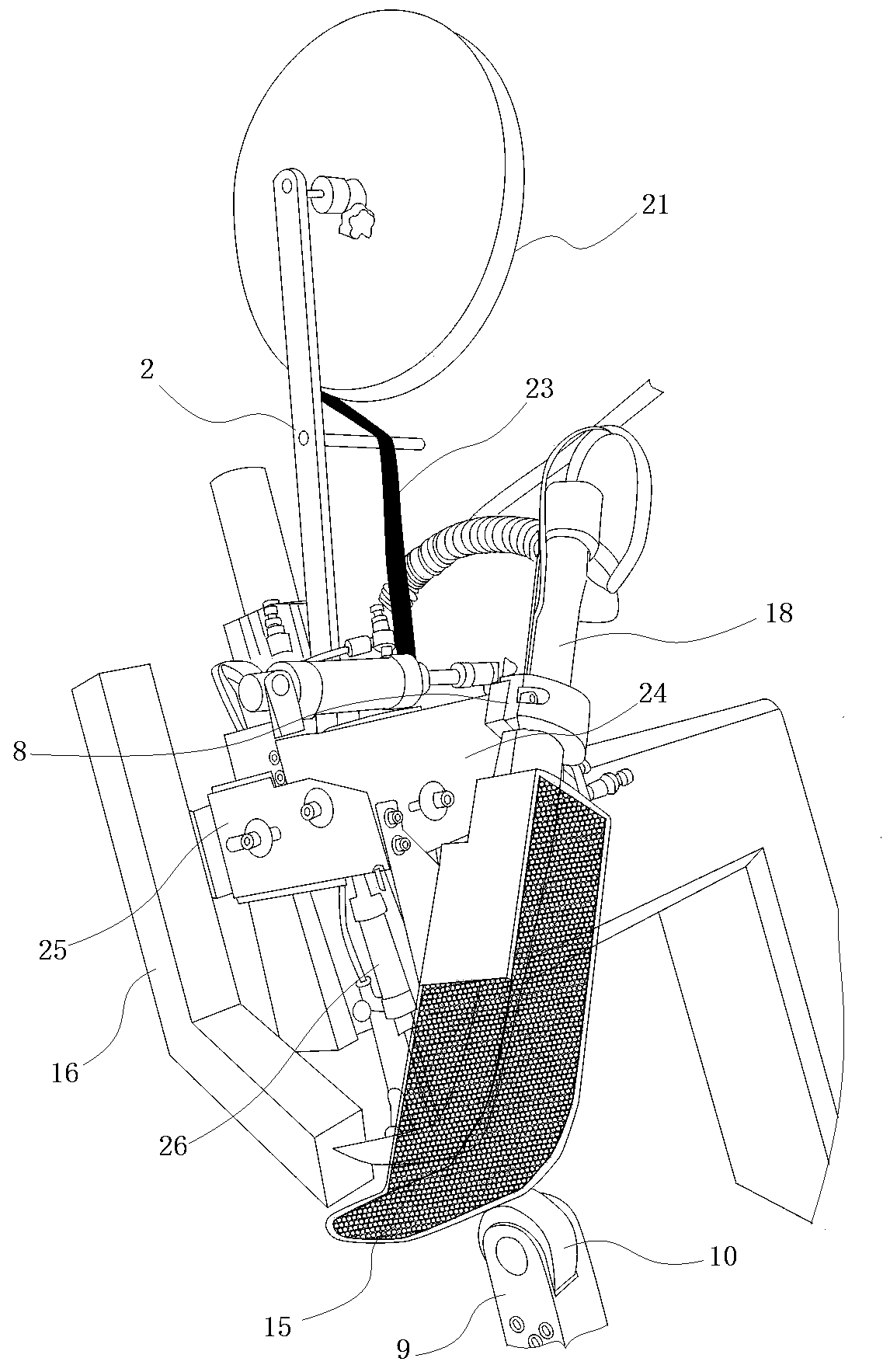

[0015] as attached Figure 1-5 As shown, the present invention includes a plastic sealing machine tray 3, a plastic sealing machine body 1 installed on the plastic sealing machine tray 3, and a heating device installed on the head of the plastic sealing machine body 1; The controller 22 on one side of the surface is connected; the heating device includes a hot air pipe 18, a vacuum pipe 4, a heating wire 20, a hot air pipe line control valve 17 and a heating resistor 19; it is installed on the slide rail of the plastic sealing body 1 head Front fixed support frame 24 and side fixed support frame 25, hinge shaft 8 is installed on the front of support 2, and described hot blast pipe 18 is obliquely installed on the front fixed support frame 24 and is connected with hinge shaft 8, and hot blast pipe circuit control valve 17 is horizontally installed on the top of the front fixed support frame 24, and the end of the hot air pipe line control valve 17 piston rod is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com