Disinfection device for plastic cup production

A technology for disinfection devices and plastic cups, which is applied in disinfection, water supply devices, sanitary equipment for toilets, etc. It can solve the problems of plastic cups that cannot be disinfected, water accumulation in the disinfection chamber, and staff burns, etc., and achieve a thorough disinfection process. , save water resources, avoid scald effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

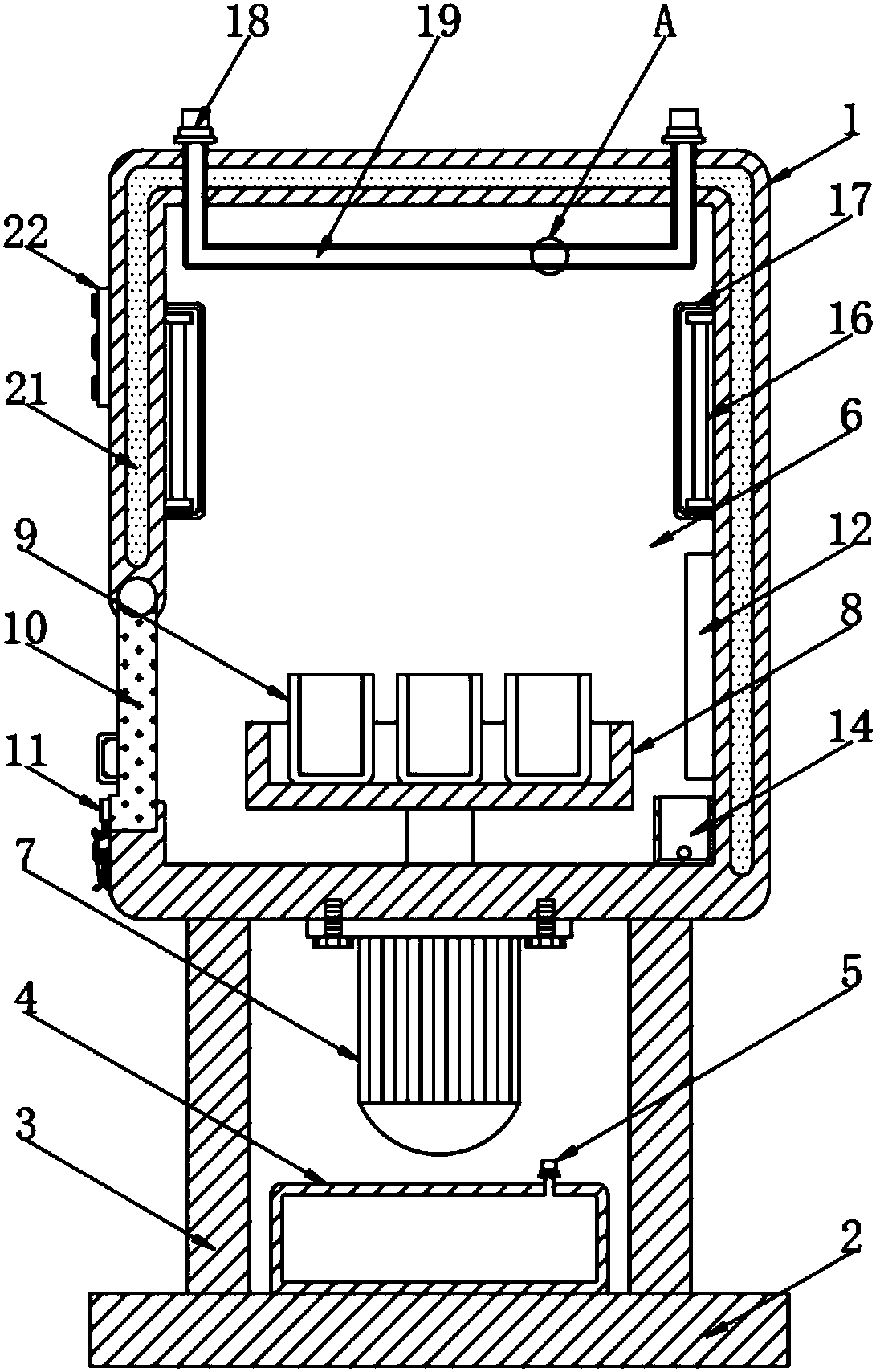

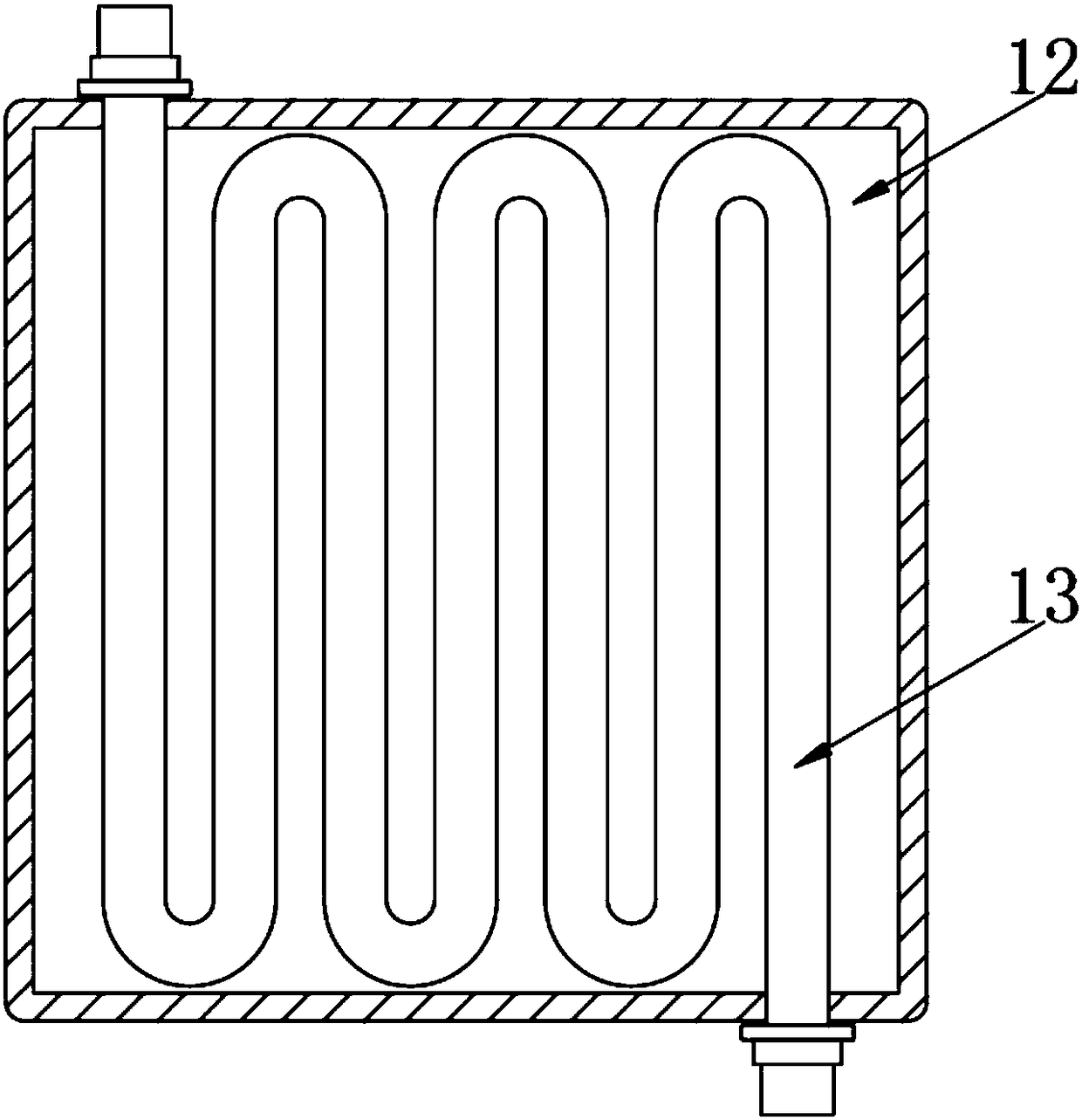

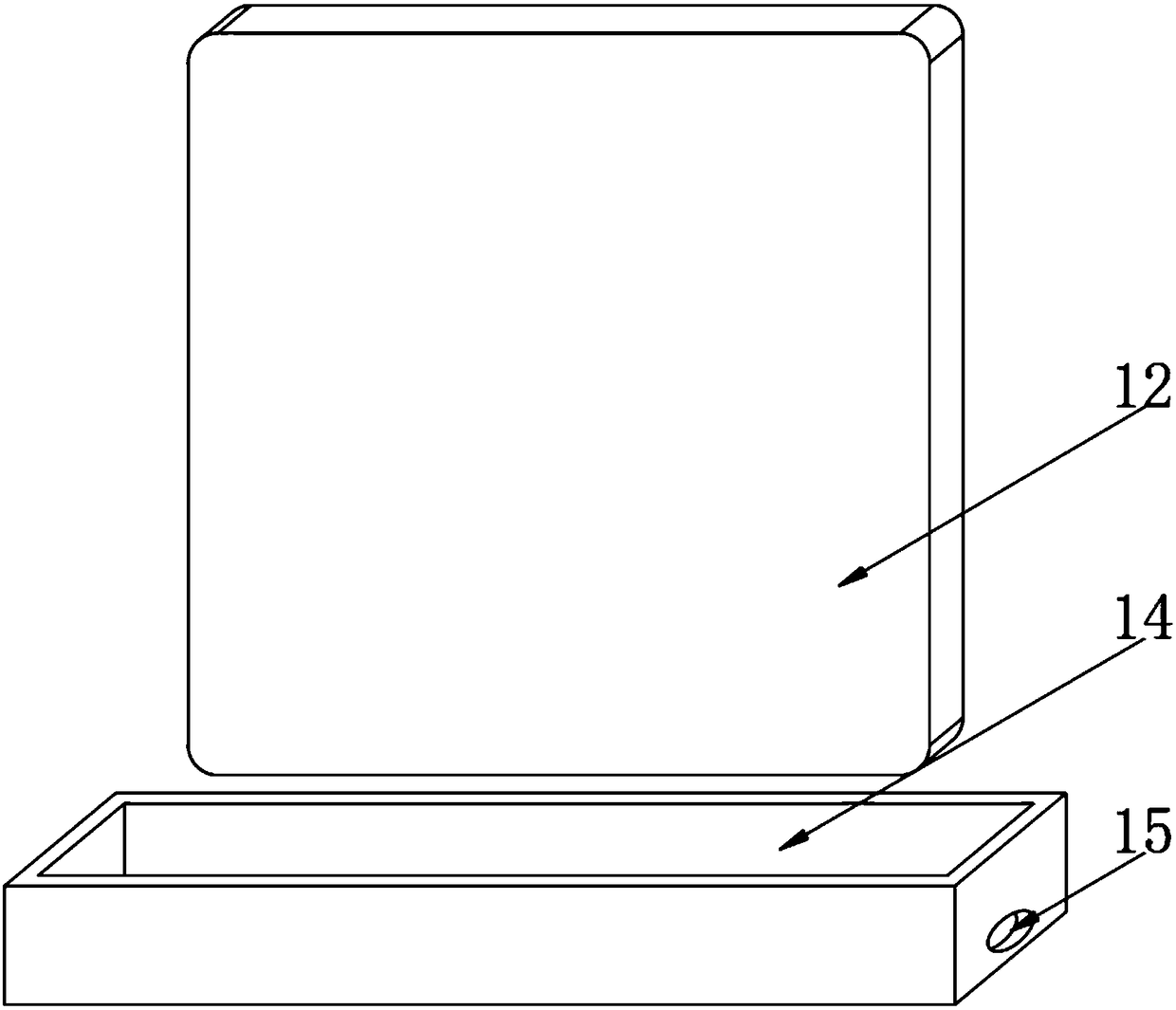

[0022] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a disinfection device for plastic cup production, comprising a device body 1, a bottom plate 2, a support rod 3, a water collection tank 4, a water inlet 5, a disinfection chamber 6, a driving motor 7, a rotating Plate 8, plastic cup 9, airtight door 10, buckle 11, condensation plate 12, condensation pipe 13, sump 14, water outlet 15, ultraviolet germicidal lamp 16, glass protective cover 17, steam outlet 18, steam pipe 19, steam Air outlet 20, asbestos 21 and control switch 22, base plate 2 is welded on the bottom of device body 1, support rods 3 are welded at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com