Variable-diameter washing robot for pipeline

A cleaning robot with variable diameter technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that the pipeline cannot move without considering the foreign matter of the robot, it is difficult to ensure consistency, and the pipeline cannot be cleaned, etc. Problems, to achieve the effect of compact structure, stable progress, normal use and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below according to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

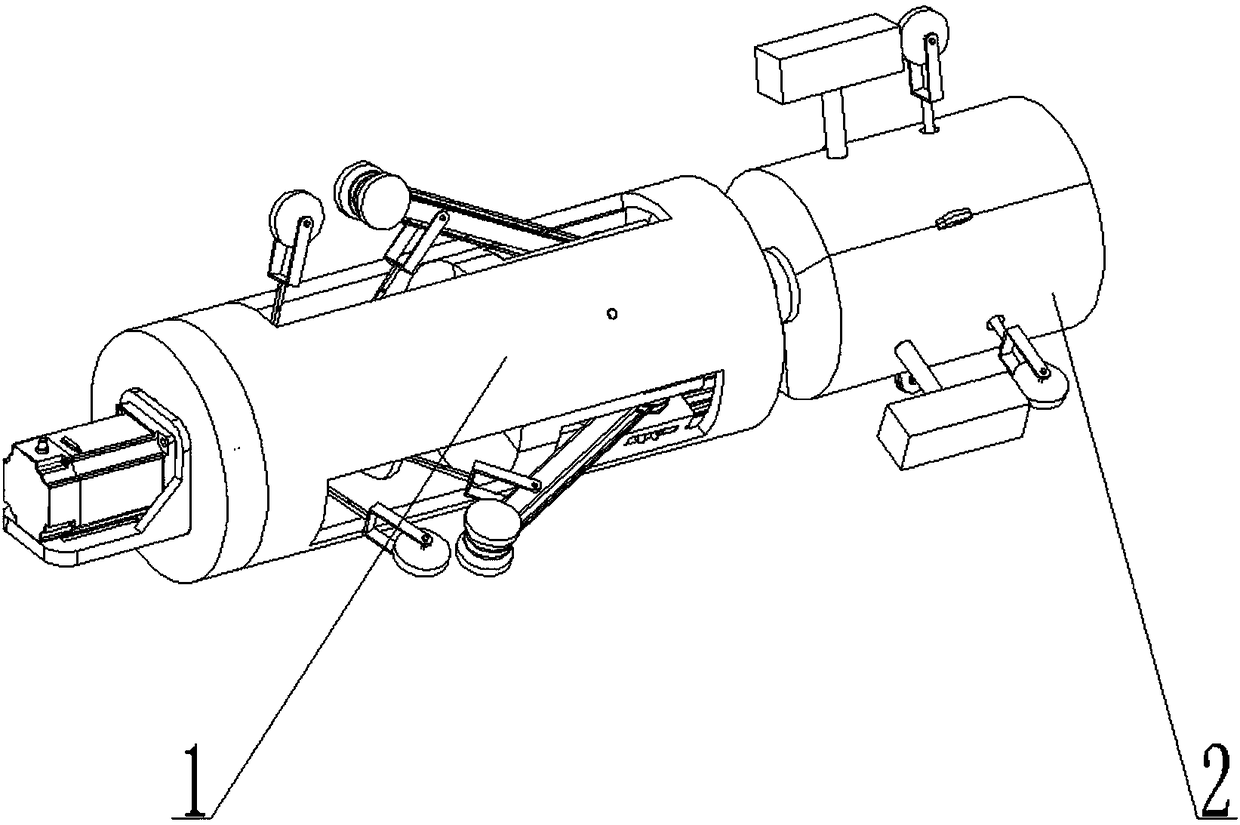

[0026] Such as figure 1 As shown, a pipeline variable diameter cleaning robot includes a supporting drive mechanism 1 for supporting and driving the entire robot and a cleaning mechanism 2 for rotating and cleaning the inner wall of the pipeline; between the supporting driving mechanism 1 and the cleaning mechanism 2 It is connected by a universal joint coupling, which can adapt to a certain degree of bending and torsion of the pipeline;

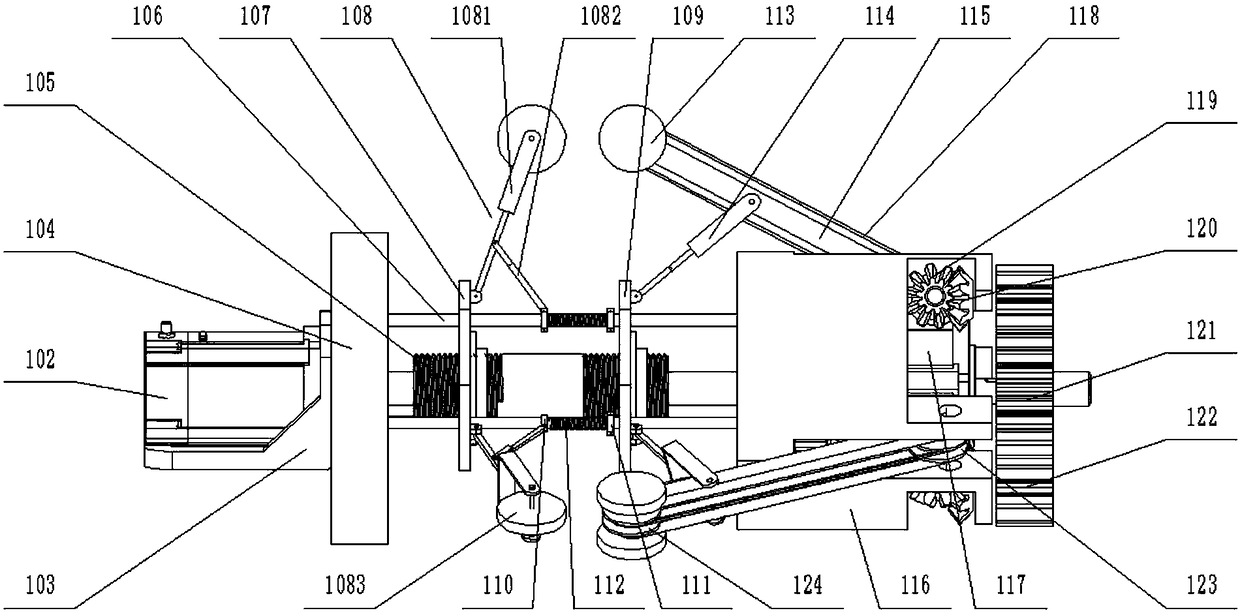

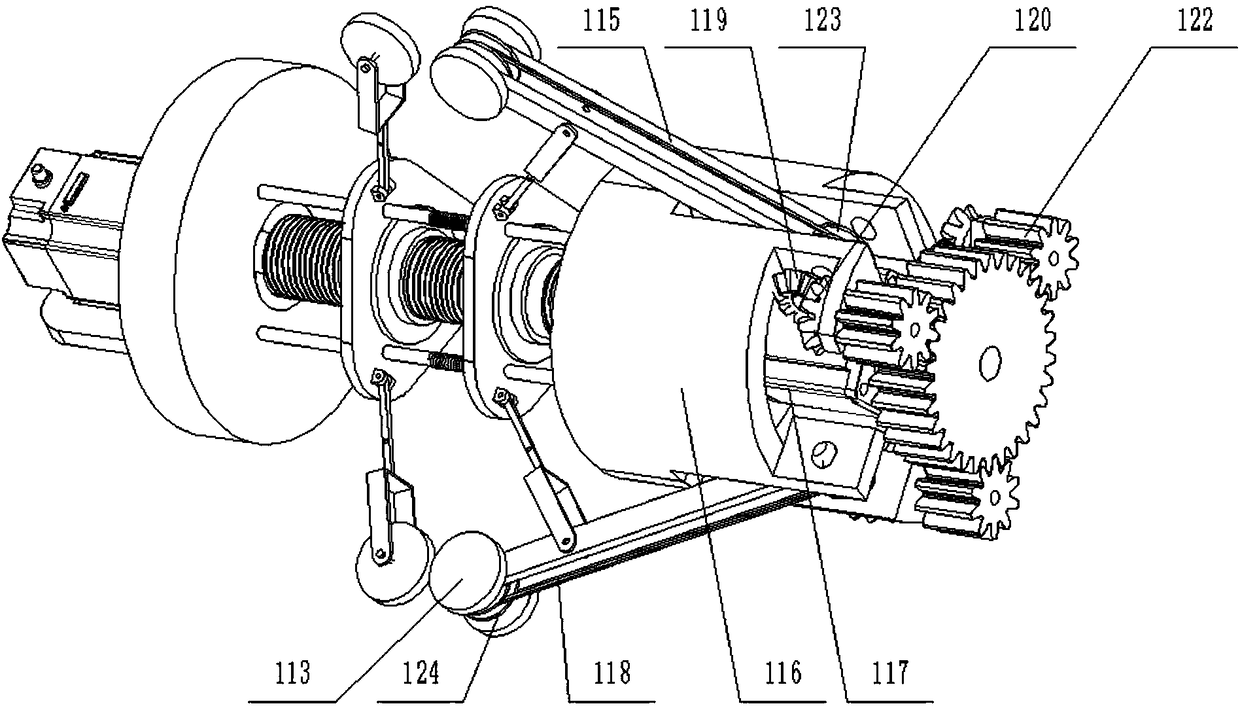

[0027] Such as figure 2 As shown, the support drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com