Die perforating device

A punching device, mold technology, applied in the direction of positioning device, driving device, feeding device, etc., can solve the problems of increased workload of operators, reduced work efficiency, and adhesion of burrs and debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

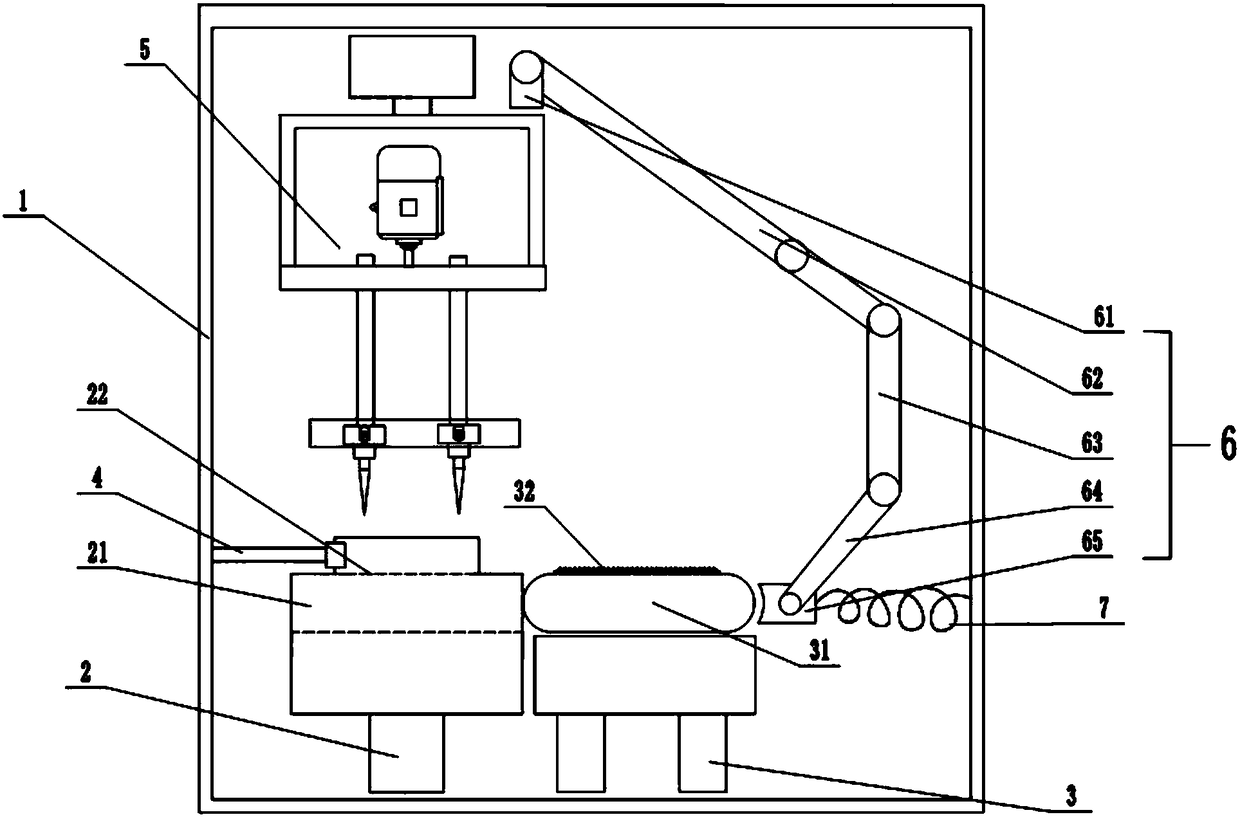

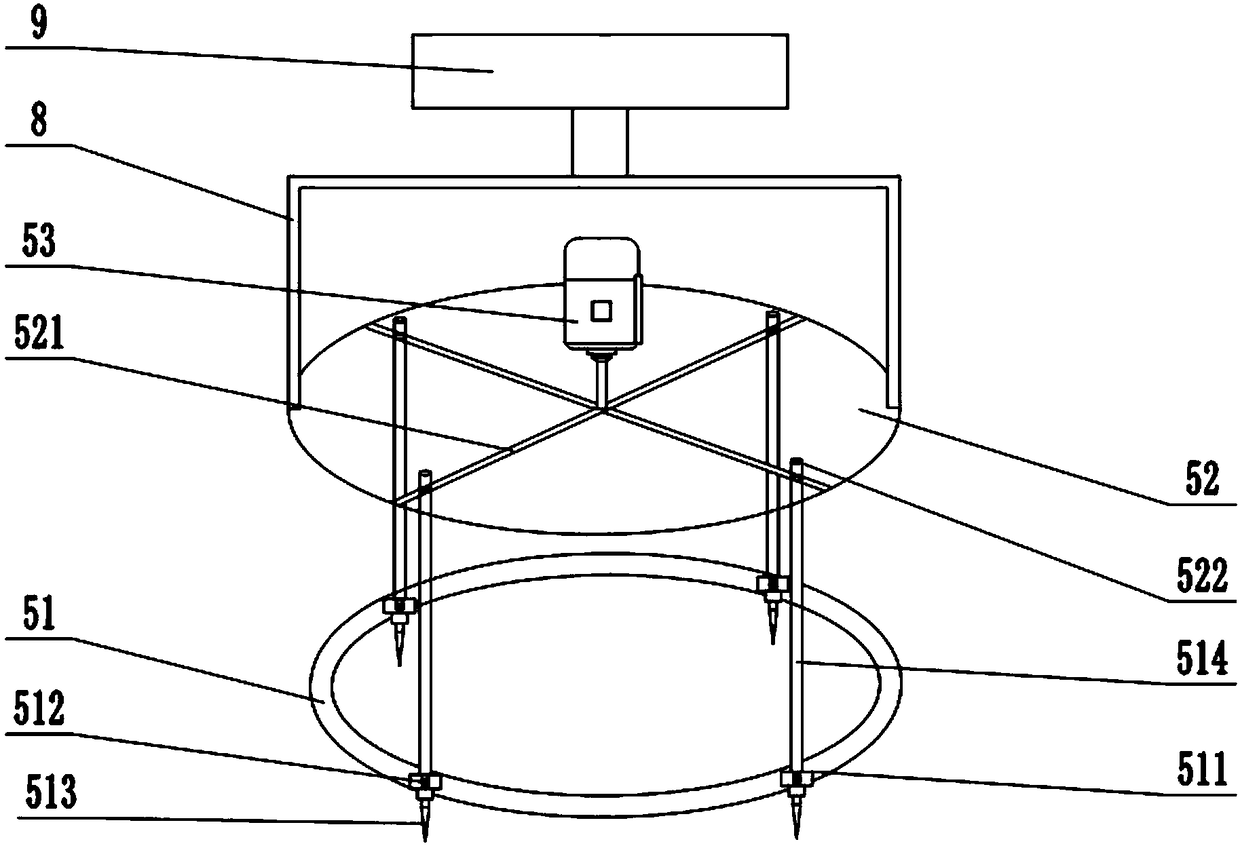

[0015] The reference signs in the drawings of the description include: frame 1, first base 2, cavity 21, opening 22, second base 3, push plate 31, frosted layer 32, clamping mechanism 4, punching device 5, ring Track 51, slide block 511, second motor 512, punching head 513, vertical rod 514, disc 52, slide bar 521, push block 522, first motor 53, linkage mechanism 6, first connecting rod 61, The second connecting rod 62, the third connecting rod 63, the push rod 64, the push block 65, the elastic member 7, the fixed plate 8, and the hydraulic cylinder 9.

[0016] The embodiment is basically as attached figure 1 - attached figure 2 Shown: a punching device for a mold, including a frame 1, a first base 2 and a second base 3 are arranged in the frame 1, a push plate 31 is slidably connected to the second base 3, and the push plate 31 is detachable A frosted layer 32 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com