Paper cutting machine for tipping paper

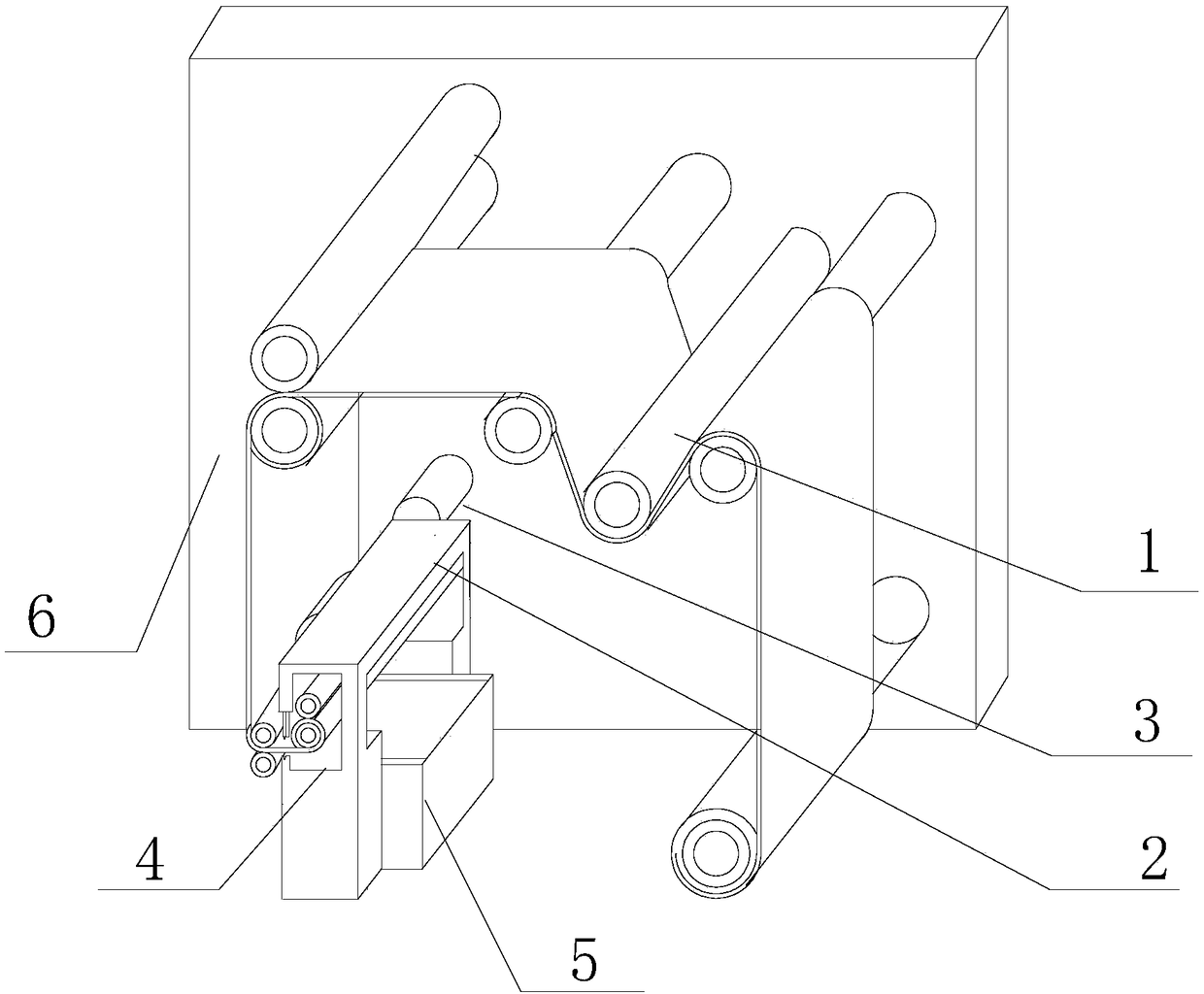

A technology of tipping paper and paper cutter, which is applied in the directions of transportation and packaging, metal processing, winding strips, etc., can solve the problems of increased ends of finished paper, the surface of the reel is not flat enough, and the paper is easily broken, etc. Achieve the effect of high degree of mechanization, novel structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

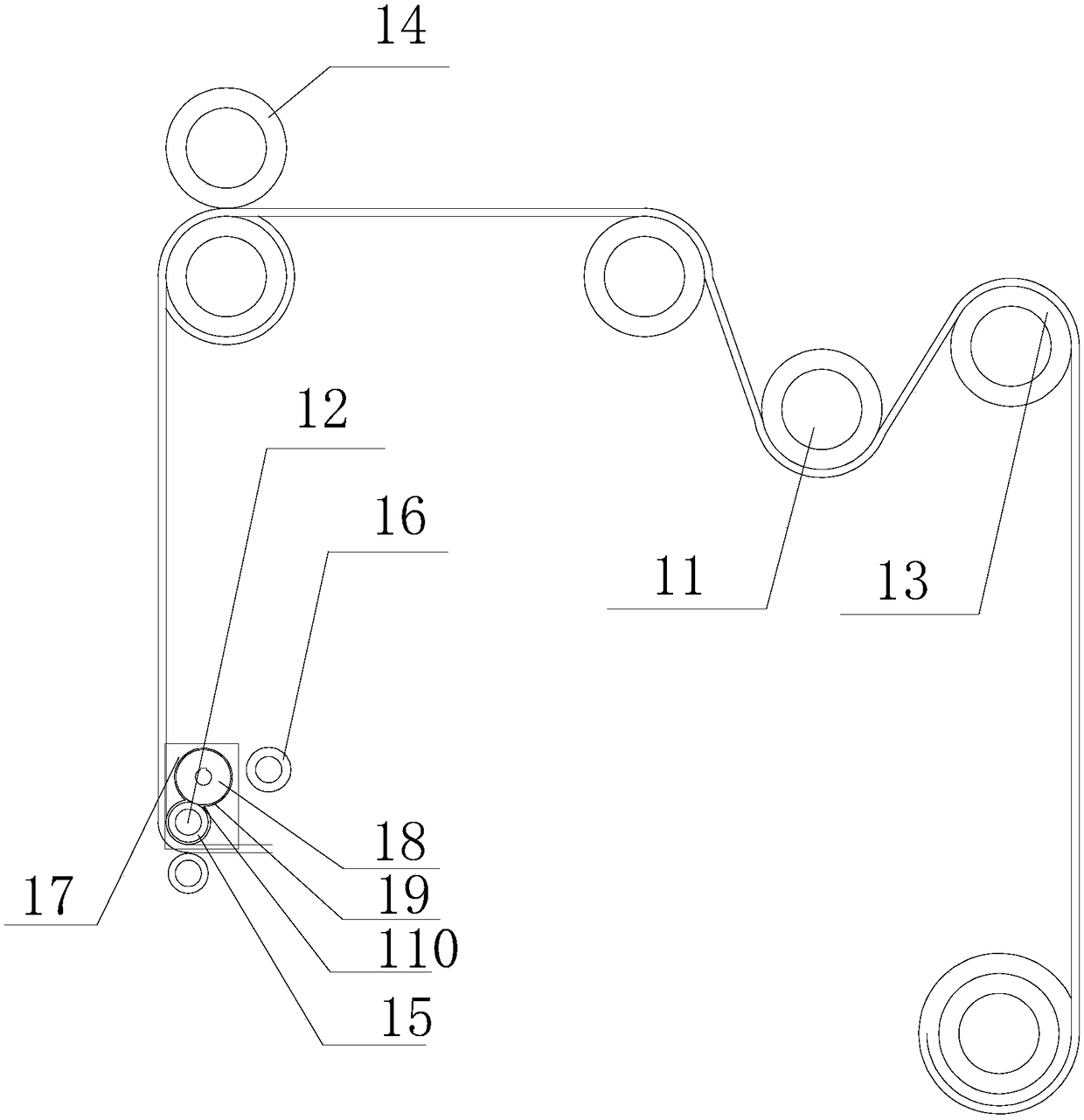

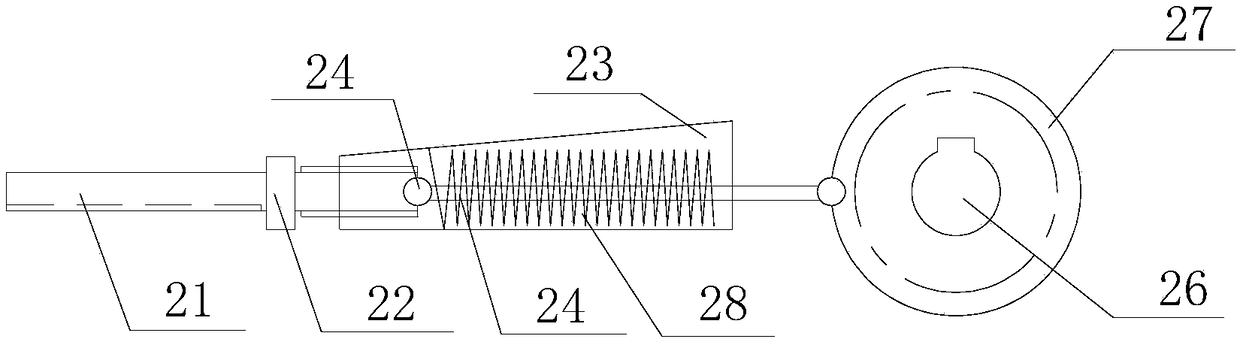

[0030] Specific implementation method: when in use, the operator bypasses the No. 1 bearing 13 and No. 3 bearing 15 with the tipping paper, sticks to the small wheel 21 at the lower end of the small wheel 21, and starts the No. 3 motor 31 to drive the small wheel 21 to rotate. When the steamboat 21 rotates one circle, the No. 4 motor 46 starts, and the processing knife 42 cuts off the tipping paper. Since the outer surface of the No. 4 bearing 16 is provided with a plurality of uniform cuts, the tipping paper that has been cut has been cut into several pieces. short paragraph.

[0031] After steamboat 21 rotated one week again, No. three motors 31 were closed, and No. two motors 26 started, and steamboat 21 moved to the right, and the tipping paper of molding fell into collection box 5 due to the blocking effect of rubber block 22 .

[0032] No. 1 motor 18 starts, and the tipping paper is driven to move to the right, and the tipping paper is stuck by the small wheel 21 again, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com