A kind of laminated tempered glass

A technology of tempered glass and interlayer steel, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve problems such as safety hazards of glass fragments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

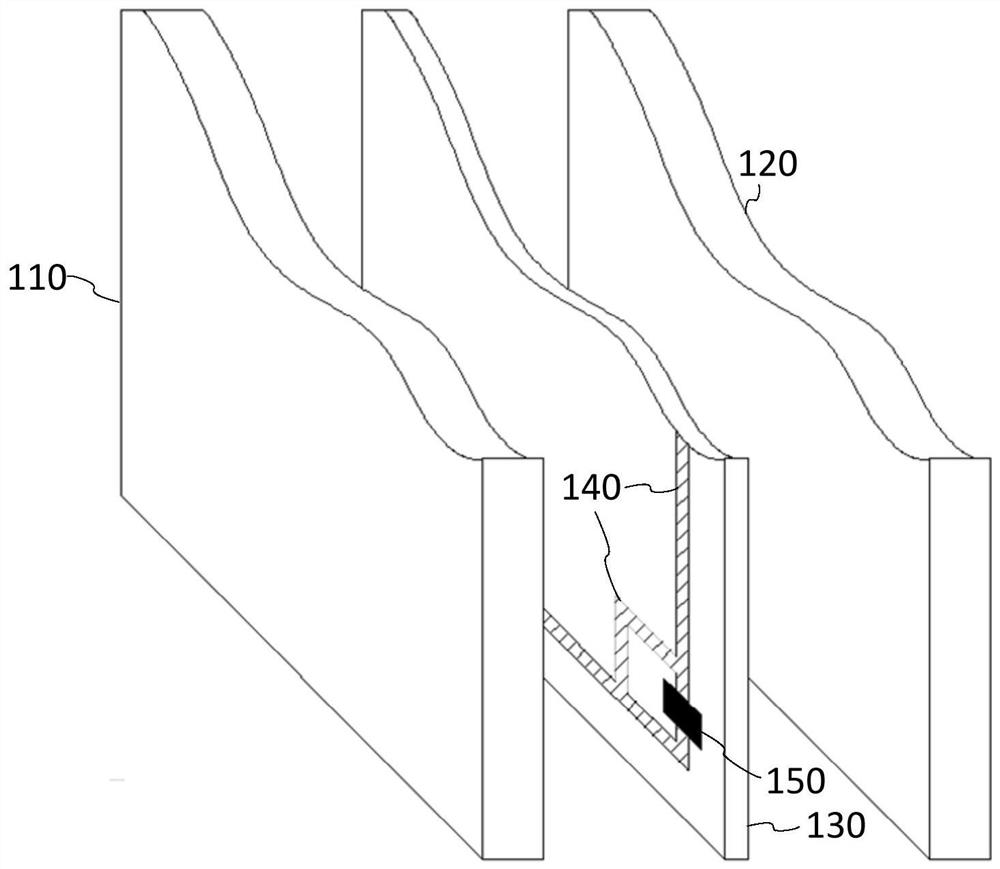

[0020] figure 1 It is a structural schematic diagram of the laminated tempered glass in Embodiment 1 of the present invention. like figure 1 As shown, the laminated tempered glass includes: a first tempered glass 110, a second tempered glass 120, an adhesive layer 130 disposed between the first tempered glass 110 and the second tempered glass 120 and on the adhesive layer 130, with RFID (Radio Frequency Identification) tags for determining whether laminated tempered glass is broken.

[0021] Wherein, the first tempered glass 110 and the second tempered glass 120 are respectively obtained by tempering ordinary float glass. The adhesive layer 130 disposed between the first tempered glass 110 and the second tempered glass 120 combines the first tempered glass and the second tempered glass into a laminated tempered glass. Wherein, the adhesive layer 130 may preferably be PVB (Polyvinyl butyral) film, SGP (ion polymer) film or EVA (polymer resin (ethylene-vinyl acetate copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com