Automatic selling equipment

An automatic vending and equipment technology, applied in solid materials, external support, transportation packaging, etc., can solve the problems of packaging bag damage, cumbersome steps, and low efficiency, and achieve the effects of avoiding damage or pollution, convenient vending, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

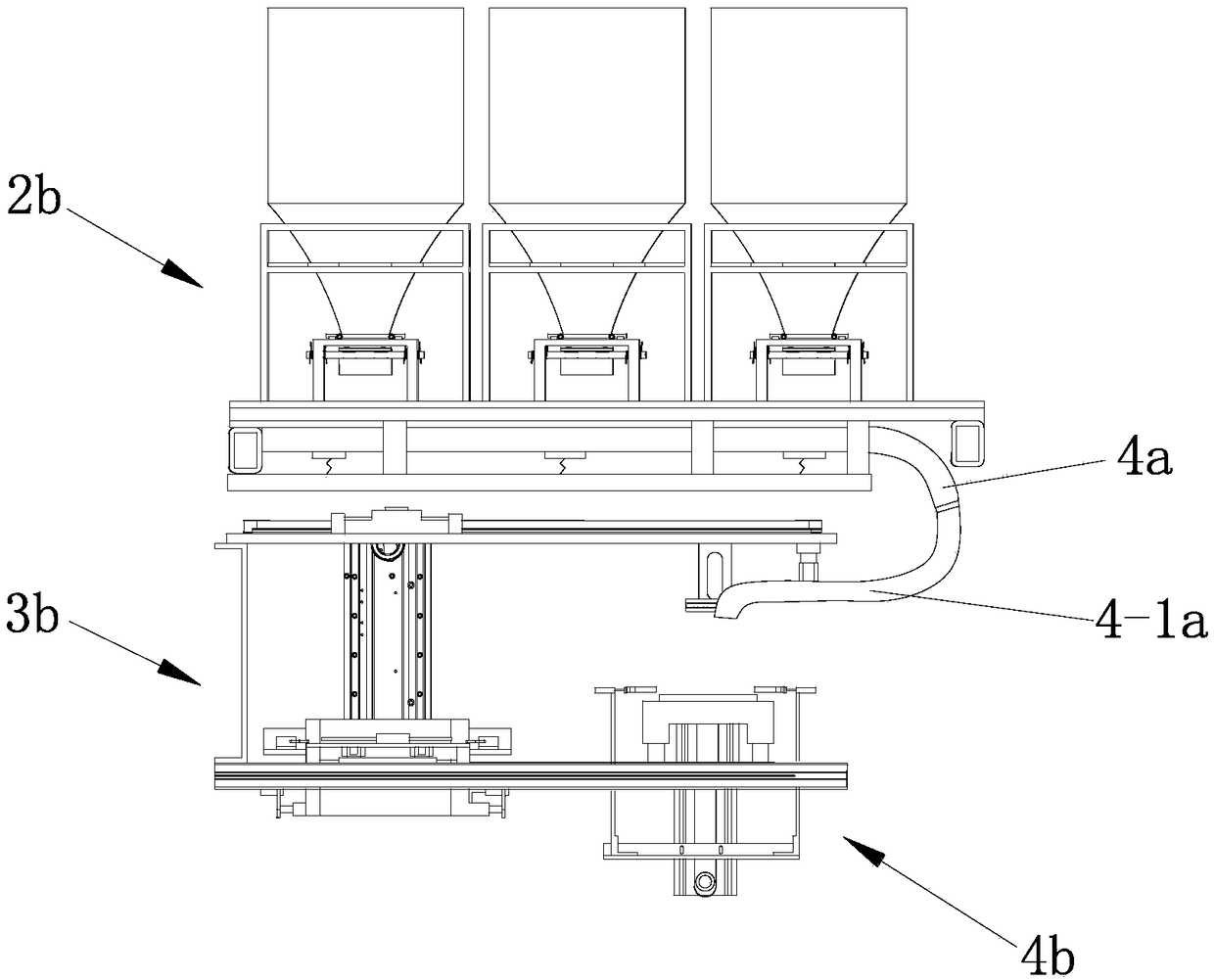

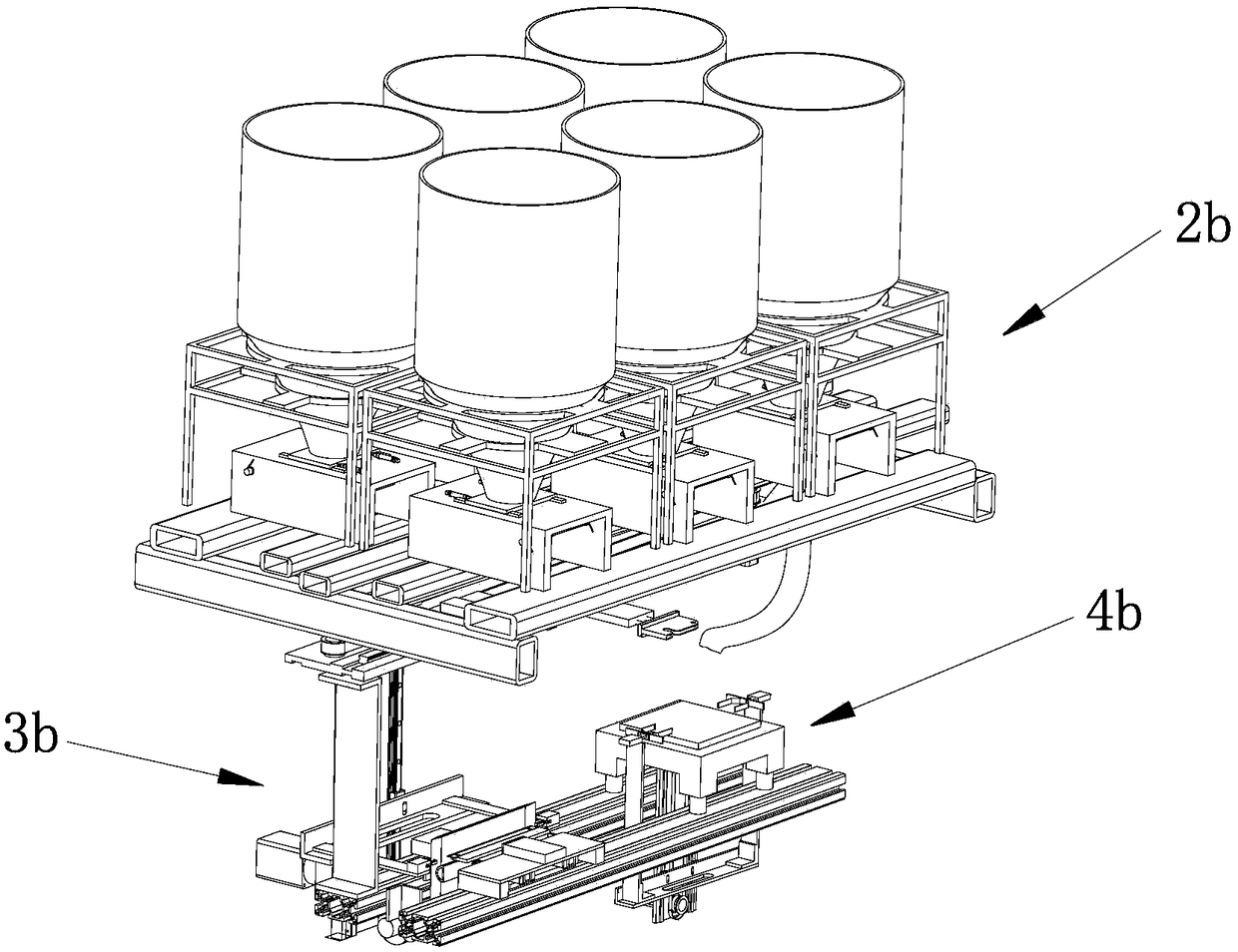

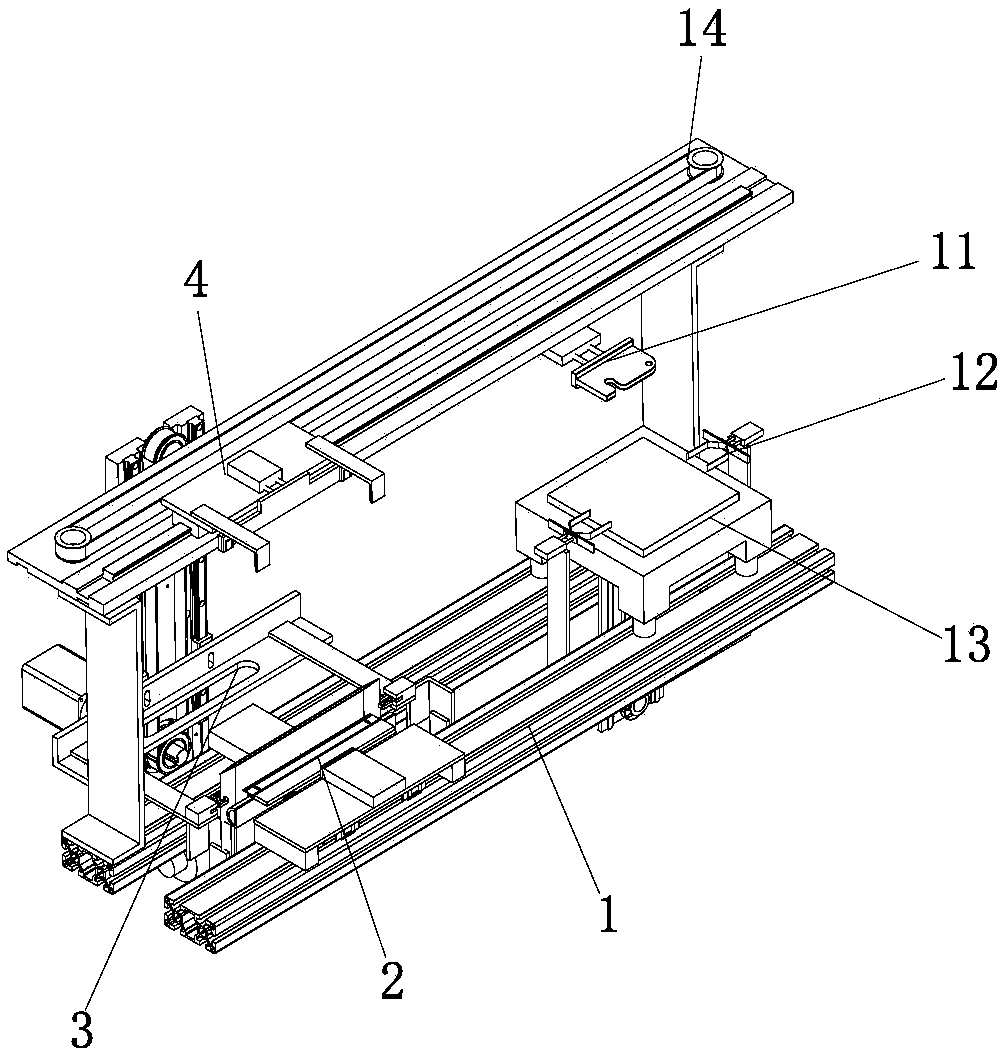

[0091] The difference between this embodiment and Embodiment 1 is that the fixing mechanism in the conveying module 3b of the packaging bag includes a clamping assembly for clamping the upper end of the packaging bag, and a clamping assembly for driving the clamping assembly to separate or close. A drive mechanism and a lifting drive mechanism for driving the clamping assembly to perform lifting movement. After the unfolding assembly leaves the sealing station, the lifting drive mechanism drives the clamping assembly to move upwards to clamp the upper end of the packaging bag, thereby avoiding interference with the movement of the unfolding assembly; in addition, the clamping assembly moves the packaging bag The upper end is fixed, so as to prevent the upper end of the packaging bag from opening too much after the goods are loaded, which is not conducive to the sealing of the mouth of the bag.

[0092] The clamping assembly and the clamping driving mechanism in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com