Pneumatic conveying feeding device`

A feeding device and pneumatic conveying technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of air flow backflow at the feeding port, complicated cleaning and unclogging operations, and blockage of the feeding device. Achieve the effect of solving pipeline blockage, improving carrying capacity and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

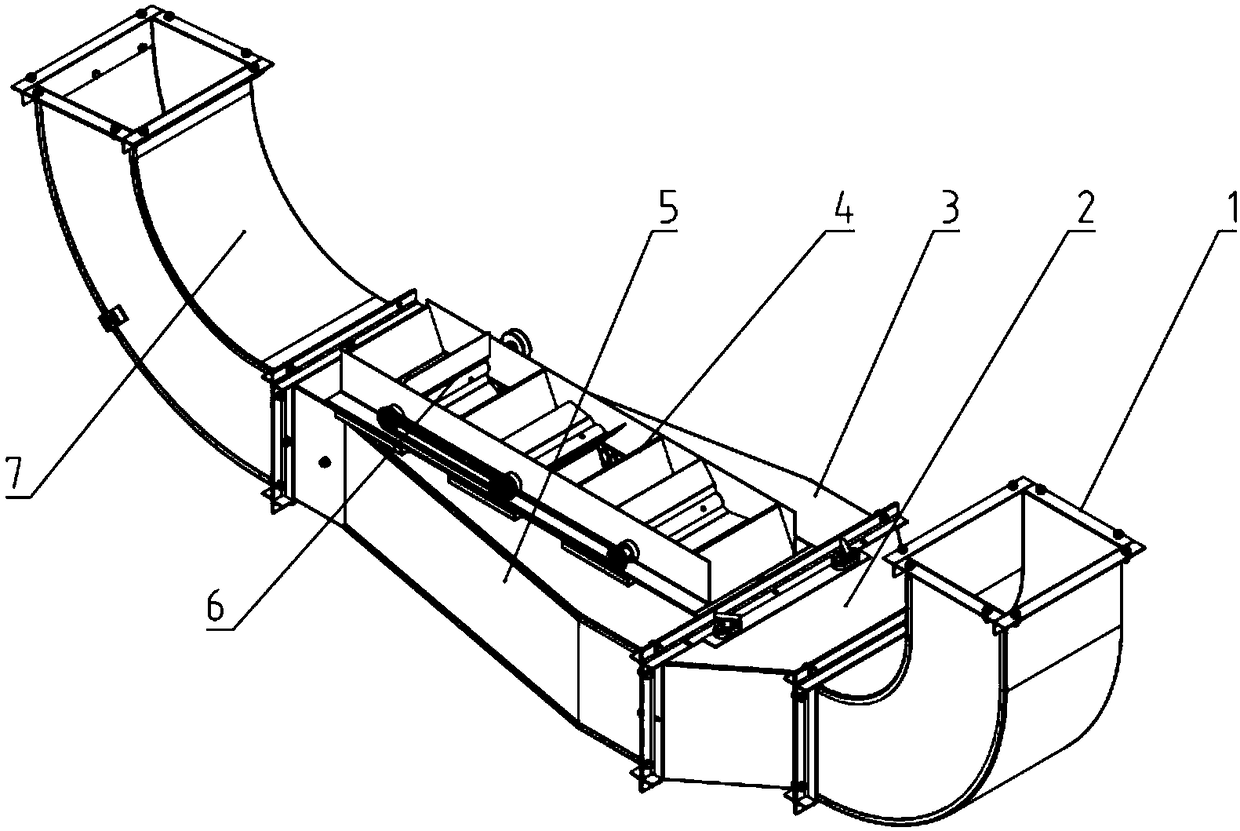

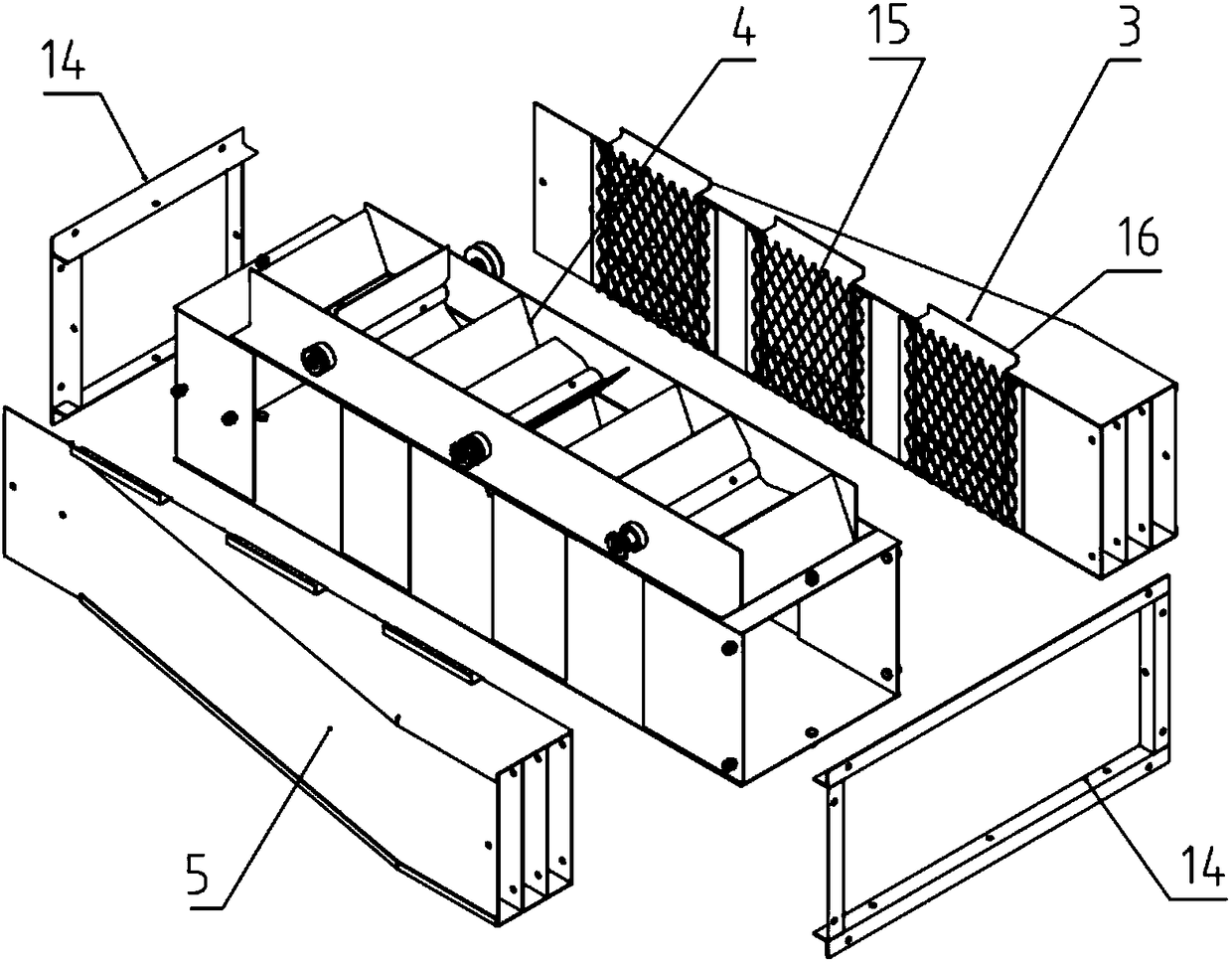

[0029] This embodiment is a pneumatic conveying feeding device matched with a full-feeding peanut picking combine harvester, and its basic structure is as follows: figure 1 As shown: the outlet of the air inlet pipe 1 connected to the air inlet of the fan outside the air inlet is respectively connected with the inlet ends of the left and right air guide pipes 5 and 3 and the middle blanking pipe 4 through the diversion control device 2, and the left and right air guide pipes 5 The inner sides of , 3 communicate with both sides of the middle drop pipe 4 through grid plate 15 respectively (referring to image 3 ), the outlet end of the middle drop pipe 4 communicates with the feed pipe 7.

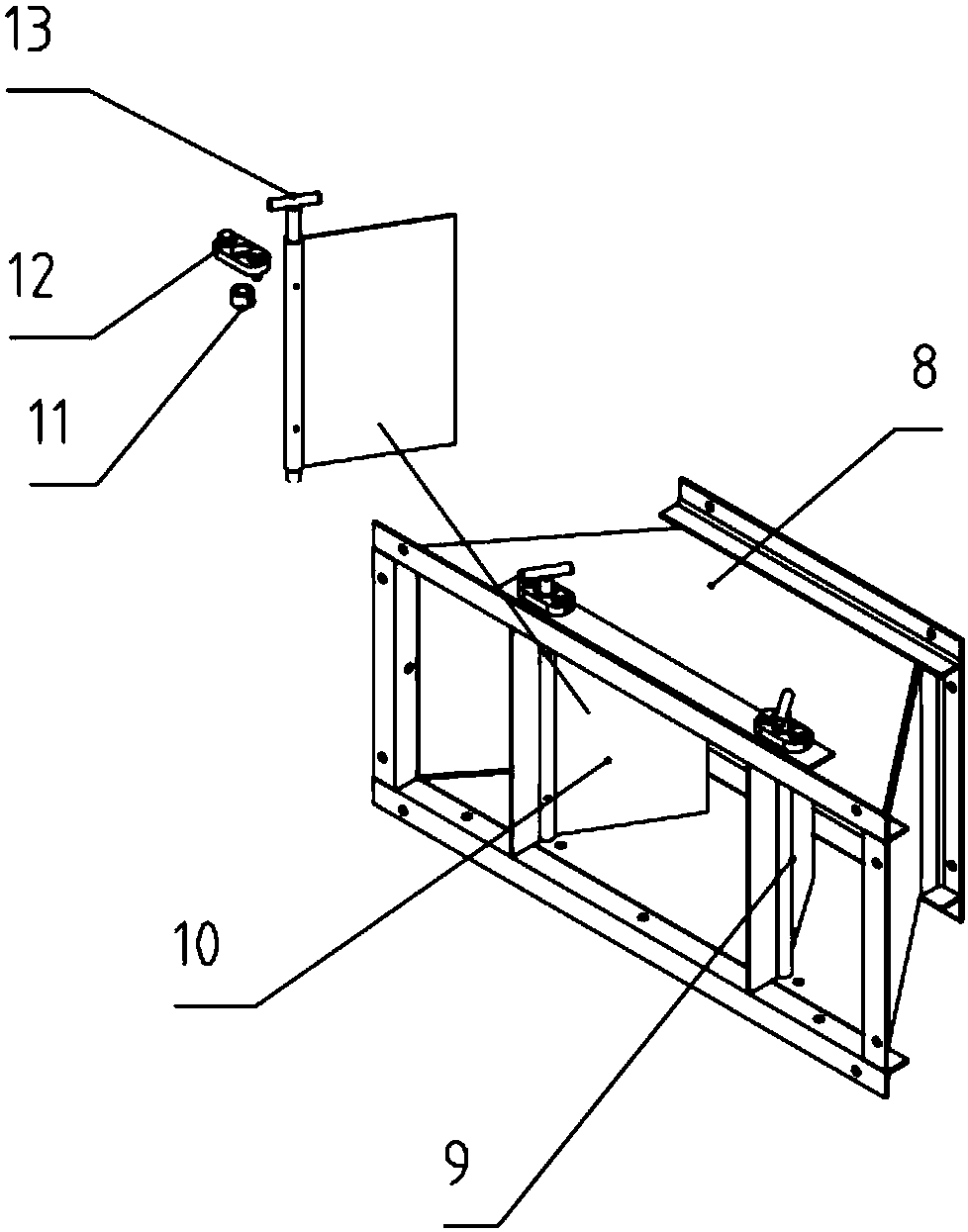

[0030] The specific structure of shunt control device 2 is as follows: figure 2 As shown, it is composed of a variable diameter tube 8 and left and right air deflectors 9 and 10 with adjustable diverging inclination angles, wherein the variable diameter tube 8 is in the shape of a bell mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com