A suspension installation method for steel foundation of tower crane

The technology of a tower crane and an installation method, which is applied in the direction of cranes and the like, can solve the problems such as the inability to complete the lifting tools, the inability to guarantee the construction period, and the waste of manpower and material resources, and achieve the effects of novel design, low cost, and high environmental protection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

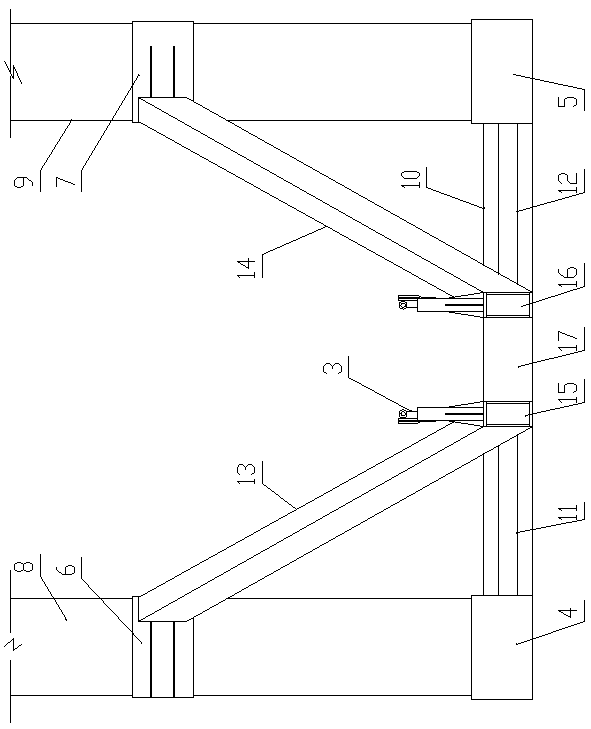

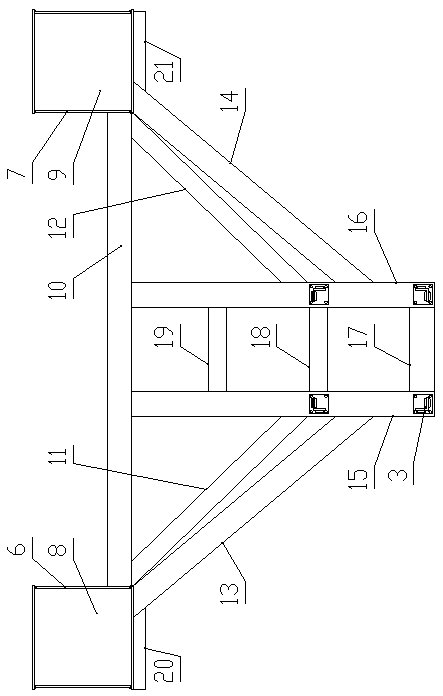

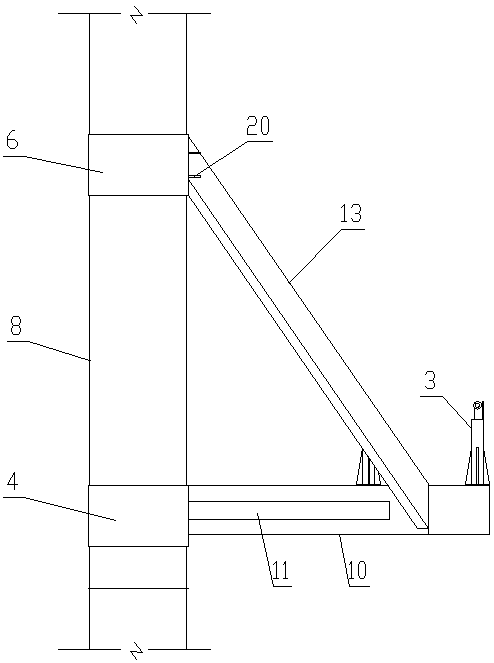

[0021] Such as Figure 1-Figure 5 Shown, a kind of tower crane steel foundation suspension installation method of the present invention comprises the following steps:

[0022] (1) Process the steel foundation 1 according to the distance between two adjacent structural columns on the outside of the building, that is, the cross-sectional size of the structural columns;

[0023] (2) At a suitable height, install the steel foundation 1 between two adjacent structural columns and extend to the outside of the building;

[0024] (3) Weld the foot 3 of the tower crane 2 to the steel foundation 1 after setting out and positioning on the steel foundation 1;

[0025] (4) According to the installation instructions of the tower crane 2 manual, install the foundation section, the bracket, the slewing assembly, the slewing tower body section, the tower top bracket assembly, the balance arm, the lifting arm until the tower crane 2 is completely installed.

[0026] According to the maximum w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com