Irregular glass processing equipment

A technology for processing equipment and special-shaped glass, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc. It can solve the problems that flat glass is easy to break, it is difficult to take out the glass, and the temperature requirements for bending and forming cannot be met. To achieve the effect of shortening the time of heat exchange, reducing the labor intensity of workers, and reducing the loss of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

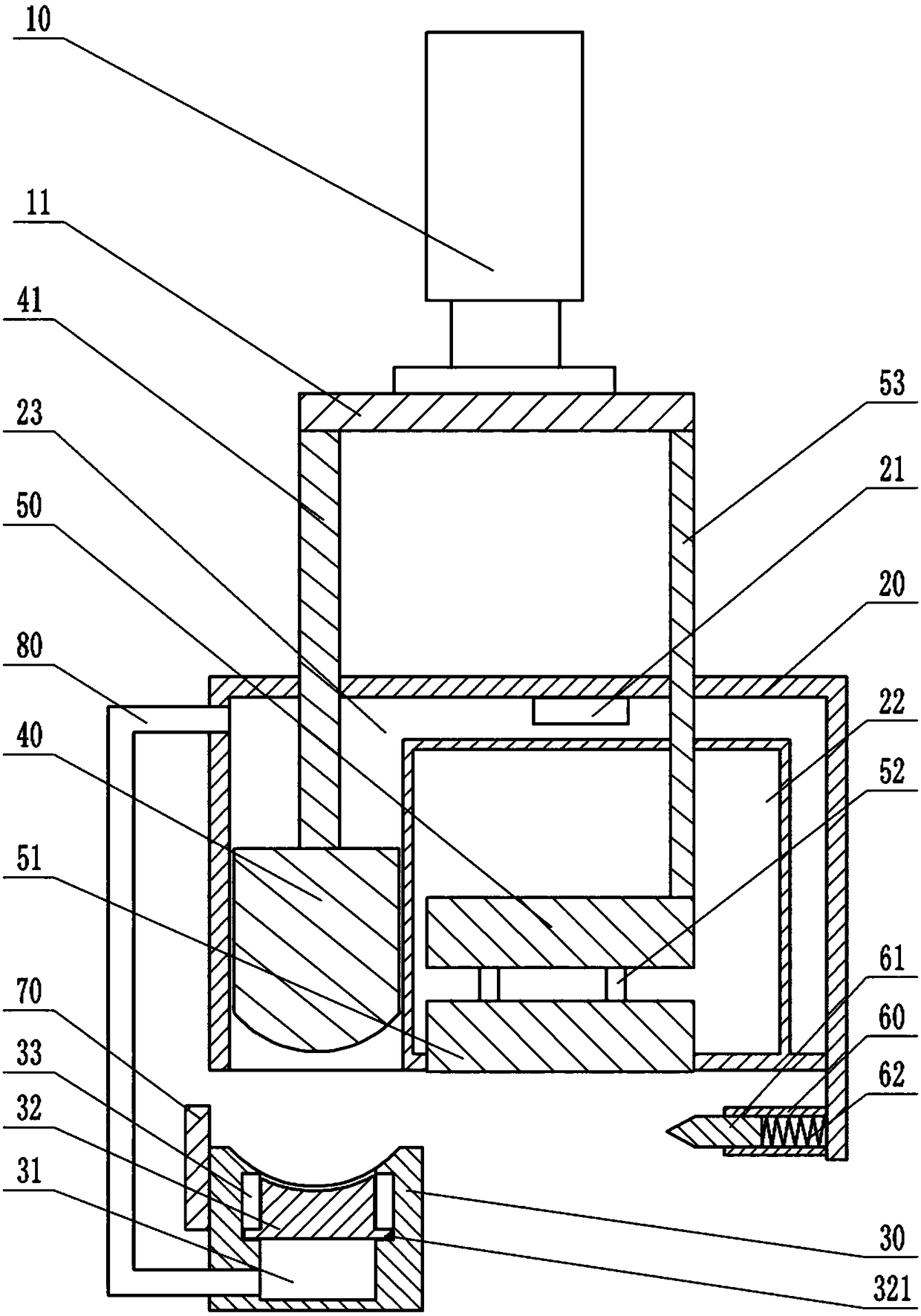

[0020] Instructions attached figure 1 The reference signs in include: hydraulic cylinder 10, cross bar 11, housing 20, electric heating wire 21, heating box 22, cavity 23, forming mold 30, cavity 31, ejector block 32, protrusion 321, Limiting chute 33, extrusion plunger 40, push rod 41, upper support block 50, lower support block 51, connecting rod 52, slide bar 53, baffle plate 70, pipeline 80.

[0021] Such as figure 1As shown, the special-shaped glass processing equipment includes a placing unit, a forming unit, an ejecting unit, a power unit, and a heating unit. The heating unit includes a shell with a cavity inside and a heating box 22 located in the shell. The heating box 22 is fixed on the bottom surface of the shell. The length, height and width of the heating box 22 are smaller than the housing 20. The front of the heating box 22 and the shell , rear, left, ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com