Chemical oil displacing method for oil reservoir after polymer oil displacement

A chemical flooding and polymer technology, applied in chemical instruments and methods, drilling composition, earthwork drilling and other directions, can solve the problems of single technical effect, complex oil displacement mechanism, low oil saturation, etc. The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

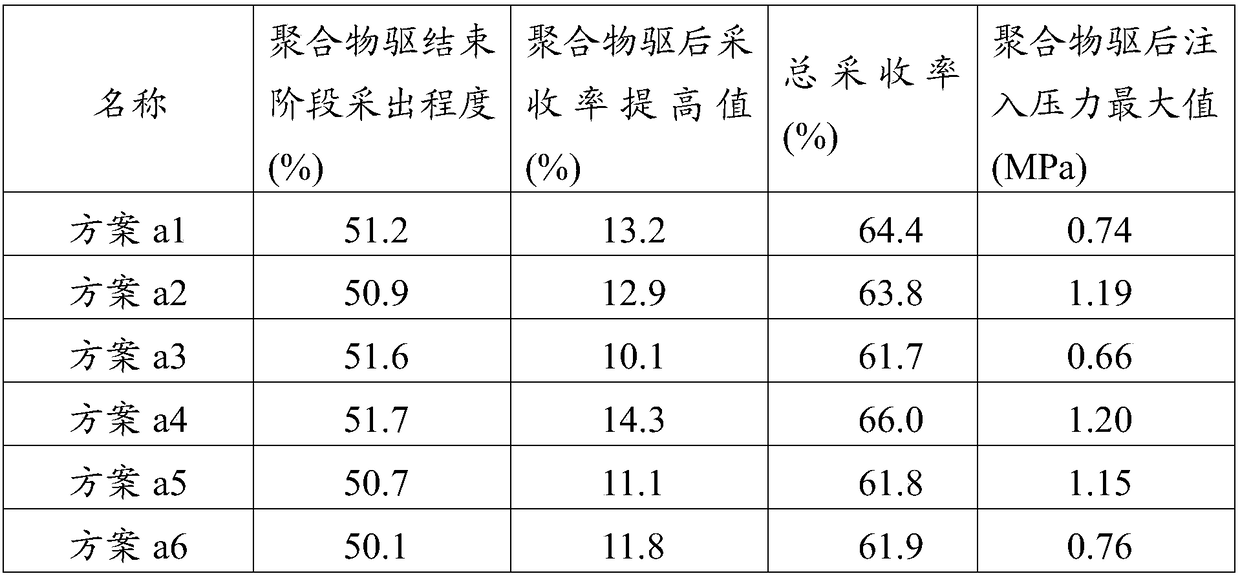

Embodiment 1

[0099] The embodiment of the present invention provides a chemical flooding method for oil reservoir after polymer flooding, and evaluates the experimental results of the chemical flooding method. The chemical flooding method is realized through the following steps:

[0100]The simulated reservoir is three layers of heterogeneous cores connected in parallel, the gas permeability is 500, 2000, 4000mD, the height is 2.0, 4.5, 1.8cm, and the length and width are 30, 4.5cm. The simulated reservoir needs to be pretreated before chemical flooding after polymer flooding. The pretreatment method is to flood the simulated reservoir with water to 95% water cut at 45°C (with no back pressure at the core outlet). %, and then inject 0.57PV of partially hydrolyzed polyacrylamide (degree of hydrolysis 21%, molecular weight 16 million, concentration 0.1%), followed by water flooding to 98% water content.

[0101] The chemical flooding after polymer flooding is carried out on the pretreated s...

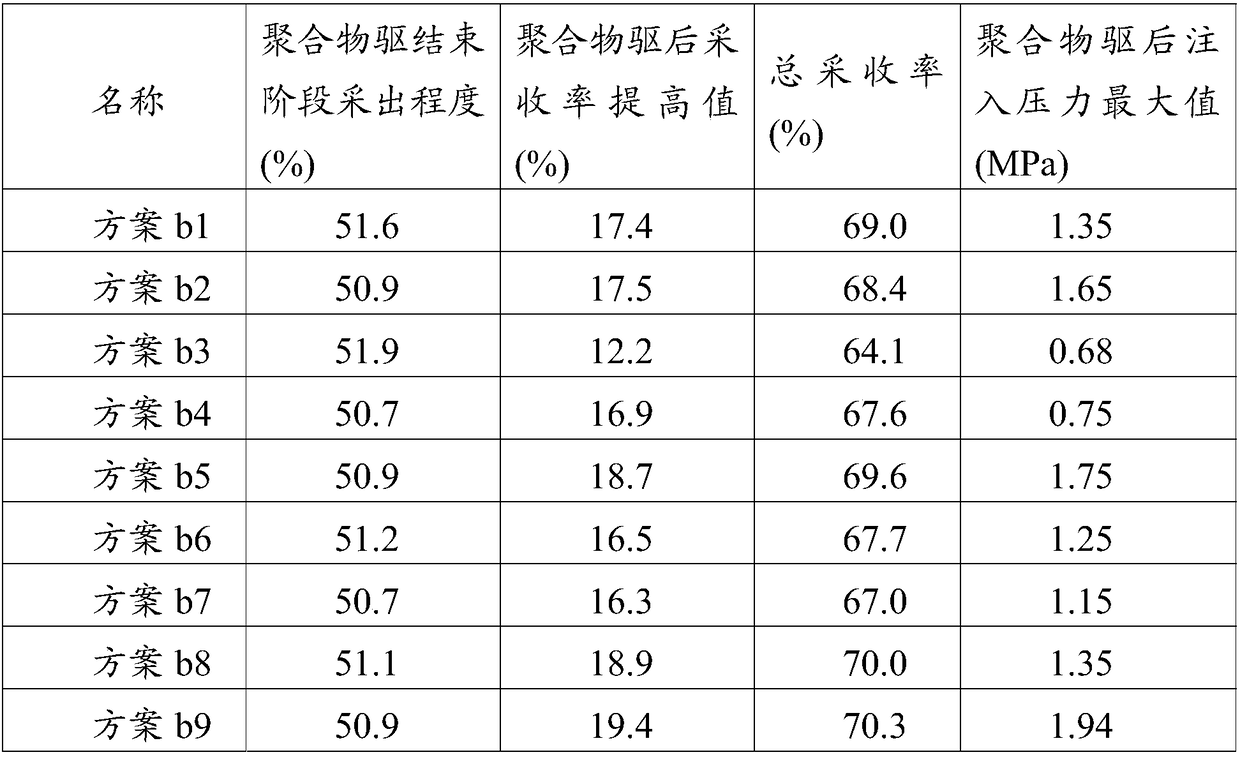

Embodiment 2

[0130] The embodiment of the present invention provides a chemical flooding method for oil reservoir after polymer flooding, and evaluates the experimental results of the chemical flooding method. The chemical flooding method is realized through the following steps:

[0131] The simulated reservoir is three layers of heterogeneous cores connected in parallel, the gas permeability is 500, 2000, 4000mD, the height is 2.0, 4.5, 1.8cm, and the length and width are 30, 4.5cm. Before chemical flooding after polymer flooding in the simulated reservoir, the simulated reservoir needs to be pretreated. The pretreatment method is to flood the simulated reservoir with water at 45°C to a water cut of 95%, and then inject 0.57PV of partially hydrolyzed polyacrylamide (The degree of hydrolysis is 21%, the molecular weight is 16 million, and the concentration is 0.1%), followed by water flooding to 98% water content.

[0132] The chemical flooding after polymer flooding is carried out on the...

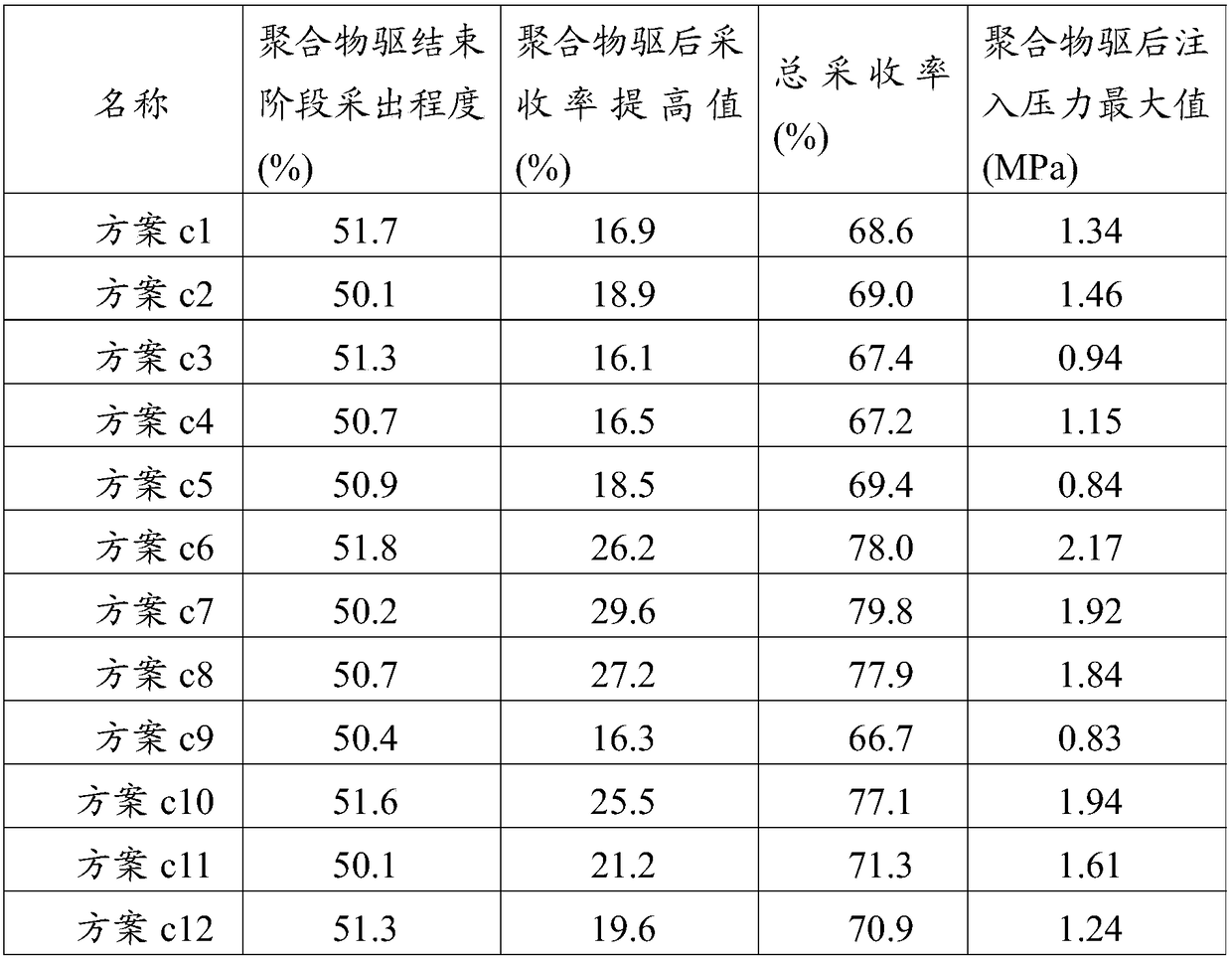

Embodiment 3

[0169] The embodiment of the present invention provides a chemical flooding method for oil reservoir after polymer flooding, and evaluates the experimental results of the chemical flooding method. The chemical flooding method is realized through the following steps:

[0170] The simulated reservoir is three layers of heterogeneous cores connected in parallel, the gas permeability is 500, 2000, 4000mD, the height is 2.0, 4.5, 1.8cm, and the length and width are 30, 4.5cm. Before chemical flooding after polymer flooding in the simulated reservoir, the simulated reservoir needs to be pretreated. The pretreatment method is to flood the simulated reservoir with water at 45°C to a water cut of 95%, and then inject 0.57PV of partially hydrolyzed polyacrylamide (The degree of hydrolysis is 21%, the molecular weight is 16 million, and the concentration is 0.1%), followed by water flooding to 98% water content.

[0171] The chemical flooding after polymer flooding is carried out on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com