Processing device and method of air-jet vortex spun blended yarn

A technology of a processing device and a processing method, applied in the textile field, can solve the problems of low production efficiency, inability to realize on-line regulation of the fiber blending ratio in the yarn and the distribution of the inner and outer layers of the fiber, and achieve the effect of improving production efficiency and enriching product types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

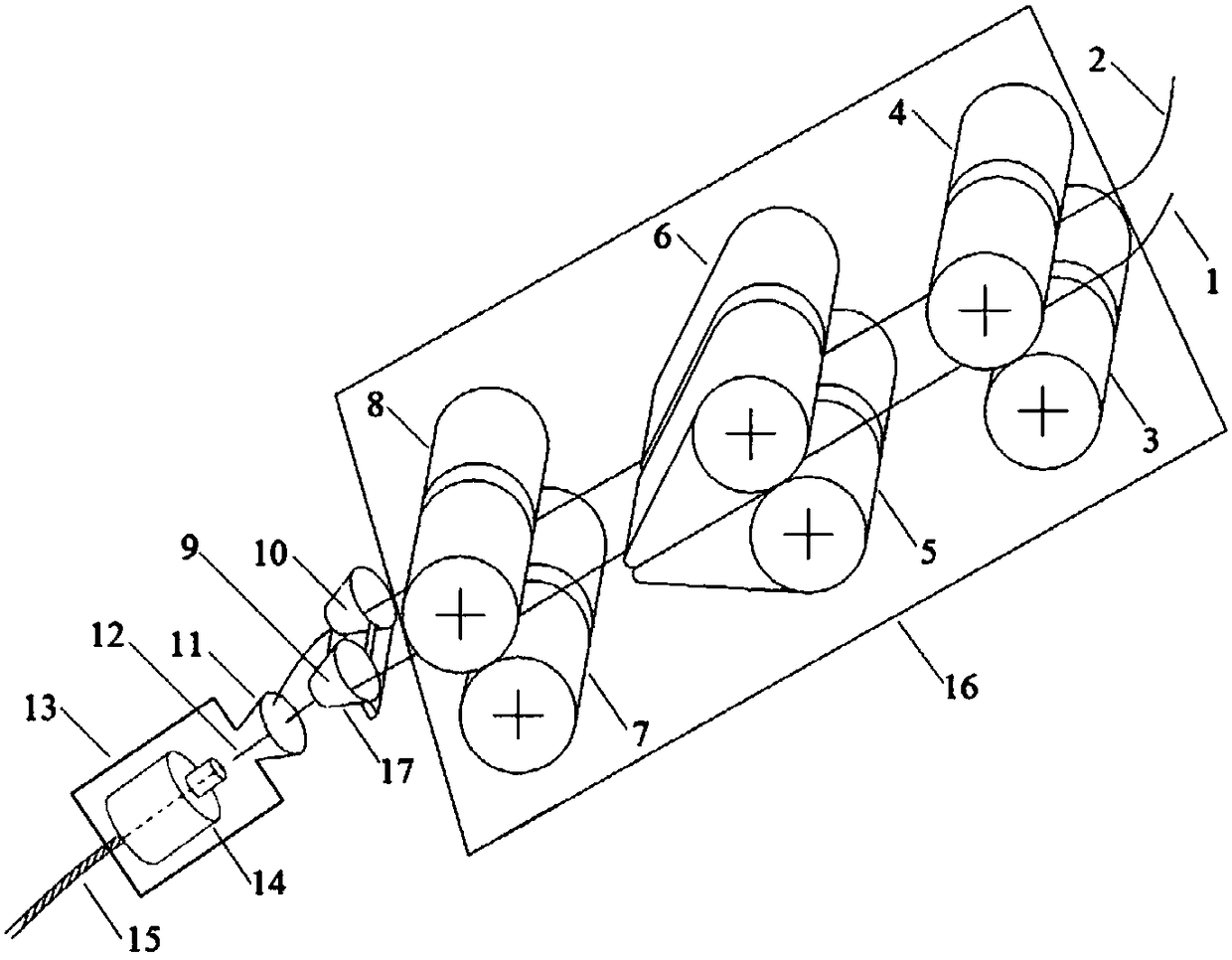

[0021] Such as figure 1 As shown, the processing device of the air-jet vortex blended yarn of the present invention comprises a double-passage drafting unit 16, and the double-passage drafting unit 16 includes a front roller group consisting of a first front roller 7 and a second front roller 8, and a front roller group composed of a first front roller 7 and a second front roller 8. The middle roller group consisting of the first middle roller 5 and the second middle roller 6, the rear roller group consisting of the first rear roller 3 and the second rear roller 4, the first front roller 7, the first middle roller 5 and the first rear roller The speed ratio of 3 and the speed ratio of the second front roller 8, the second middle roller 6 and the second rear roller 4 can be adjusted online; between the outlet of the first front roller 7 and the second front roller 8 and the nozzle inlet 11 Two-channel bell mouth cluster 17 is installed between them, said dual channel bell mouth...

Embodiment 2

[0027] The processing method of the air-jet vortex blended yarn of the present invention adopts the processing device described in Embodiment 1 to process, including double-channel drafting, air-twisting and yarn-drawing winding;

[0028] The dual-channel drafting adopts a dual-channel drafting unit 16 to respectively regulate the drafting multiple and feeding speed of the first short fiber strand 1 and the second short fiber strand 2, and configure two groups of final air-jet vortex blended yarns online. Fiber blending ratio;

[0029] The air-twisting uses a dual-channel bell-mouth cluster 17 to control the position of the first short fiber sliver 1 and the second short fiber sliver 2 fed into the nozzle inlet 11, and the two components of the final air-jet vortex spinning blended yarn are regulated online. The fibers are distributed inside and outside, and the quantitative first short fiber strands 1 drawn by the first front roller 7, the first middle roller 5 and the first ...

Embodiment 3

[0033] Such as figure 1 As shown, the processing device of the air-jet vortex blended yarn of the present invention comprises a double-passage drafting unit 16, and the double-passage drafting unit 16 includes a front roller group consisting of a first front roller 7 and a second front roller 8, and a front roller group composed of a first front roller 7 and a second front roller 8. The middle roller group consisting of the first middle roller 5 and the second middle roller 6, the rear roller group consisting of the first rear roller 3 and the second rear roller 4, the first front roller 7, the first middle roller 5 and the first rear roller The speed ratio of 3 and the speed ratio of the second front roller 8, the second middle roller 6 and the second rear roller 4 can be adjusted online; between the outlet of the first front roller 7 and the second front roller 8 and the nozzle inlet 11 Two-channel bell mouth cluster 17 is installed between them, said dual channel bell mouth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com