Cardboard paper pulping system

A container board paper and pulping technology, which is applied in the pulp beating method, pulp beating/refining method, papermaking, etc., can solve the problems of waste of fiber resources, waste of resources, and affecting the quality of kraft cardboard, so as to increase production capacity and improve Quality, the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

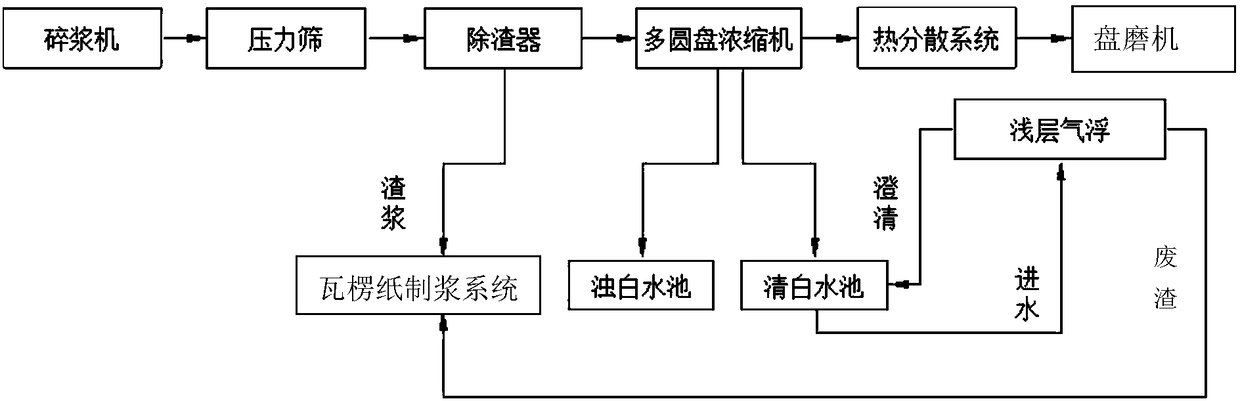

[0017] Such as figure 1 As shown, the boxboard pulping system includes a cattle cardboard pulping system and a corrugated paper pulping system, and the cattle cardboard pulping system includes a pulper, a pressure screen, a slag remover, a multi-disc thickener, The heat dispersion system and the disc mill, the pulp outlet of the pulper is connected with the pulp inlet of the pressure screen, the pulp outlet of the pressure screen is connected with the pulp inlet of the slag remover, and The slurry outlet of the slag remover is connected with the slurry inlet of the multi-disk thickener, and the slurry outlet of the multi-disk thickener is connected with the slurry inlet of the thermal dispersion system. The slurry outlet of the thermal dispersion system The port is connected with the pulp inlet of the disc mill, and the slurry outlet of the slag remover is connected with the corrugated paper pulping system. The sludge filtered by the slag remover in the ox cardboard pulping sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com