Method for treating deep loose and soft rock stratum roadway floor heave through jet grouting piles

A technology for rotary jetting piles and rock formations, which is applied in drilling equipment and methods, sheet pile walls, and earthwork drilling and mining, etc., can solve the problems that the recovery of steel beams cannot meet the requirements, the height of the wall is limited, and the construction is difficult, and it is convenient to achieve. Effects of transportation and pedestrian walking, avoiding the deterioration of stress state, reducing psychological burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

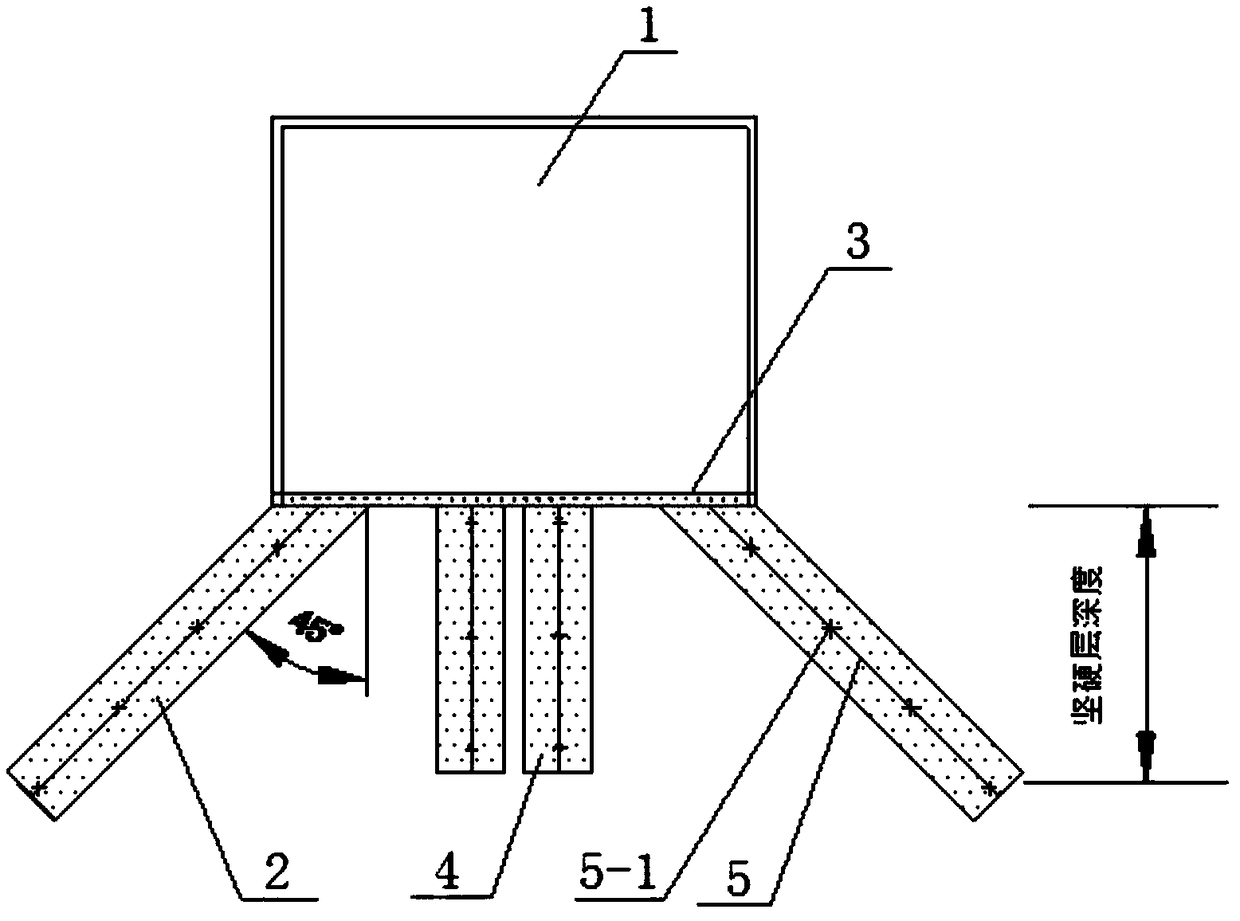

[0028] Such as figure 1 As shown, the method for controlling the floor heave of deep soft rock formation roadway with rotary grouting piles includes the following steps:

[0029] Step 1: Peek into the bottom plate rock formation: on the bottom plate 3 of the soft and broken roadway 1 in the deep well, use the drilling peep instrument to peek into the bottom plate 3 rock formation at the center of the cross section of the roadway 1. The designed drilling depth is 10-15m, and the diameter of the drill hole 28mm. Considering that the drilling powder is not easy to discharge when drilling downward, the actual drilling depth is 2m longer than the designed drilling depth. Use a drilling rig to drill a 12-17m drilling hole from the bottom plate 3, turn on the peeping instrument, and extend the peeping instrument probe. Into the borehole, video recording and recordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com