Hexagonal volute

A hexagonal and volute technology, which is applied in the field of centrifugal fan application equipment, can solve the problems of large position deviation between the center line of the air outlet and the horizontal center line of the volute, poor uniformity of the air flow, and high air flow noise, so as to achieve a Uniform performance improvement, reduced installation space, and reduced airflow noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below by means of the accompanying drawings and examples.

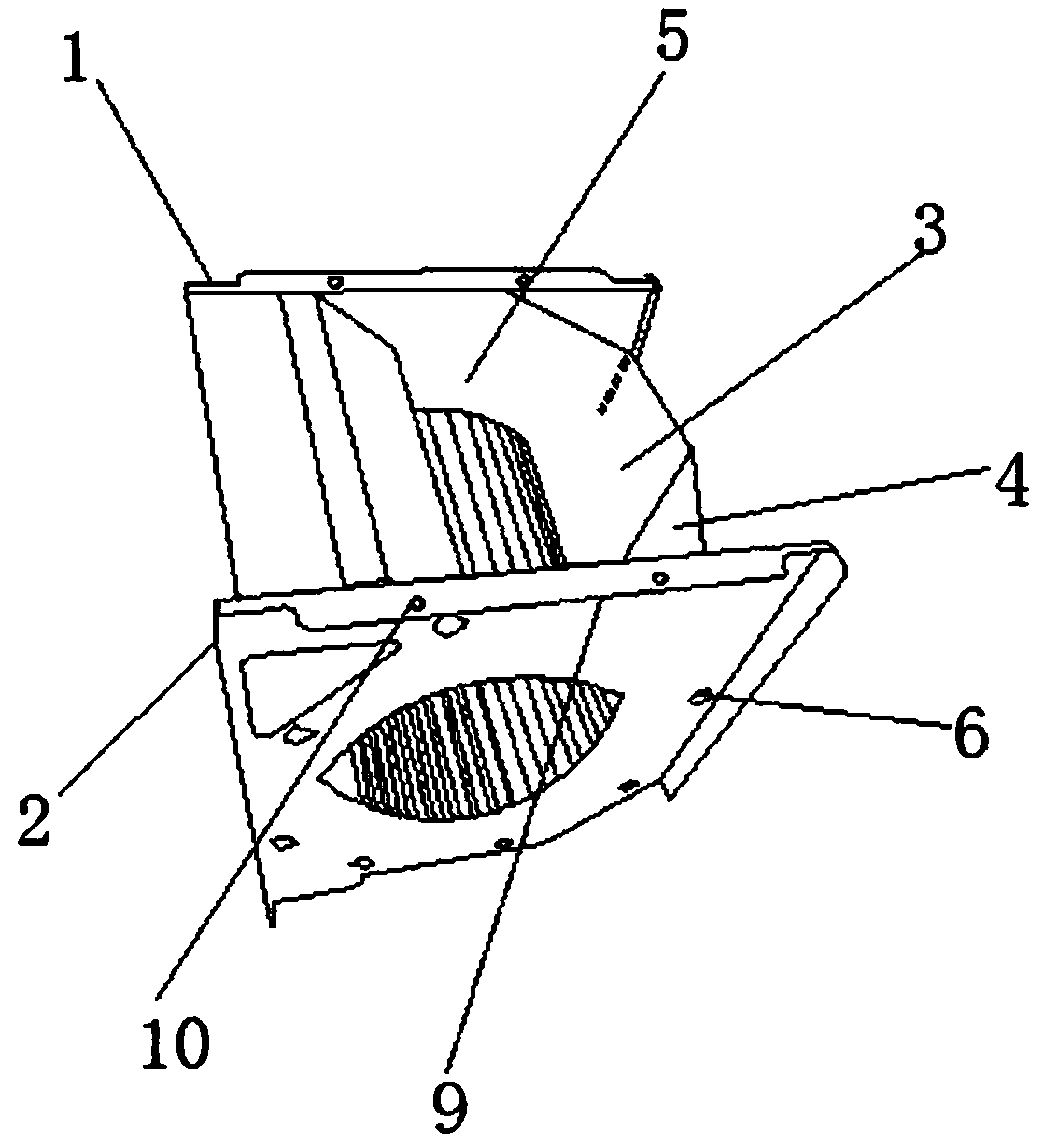

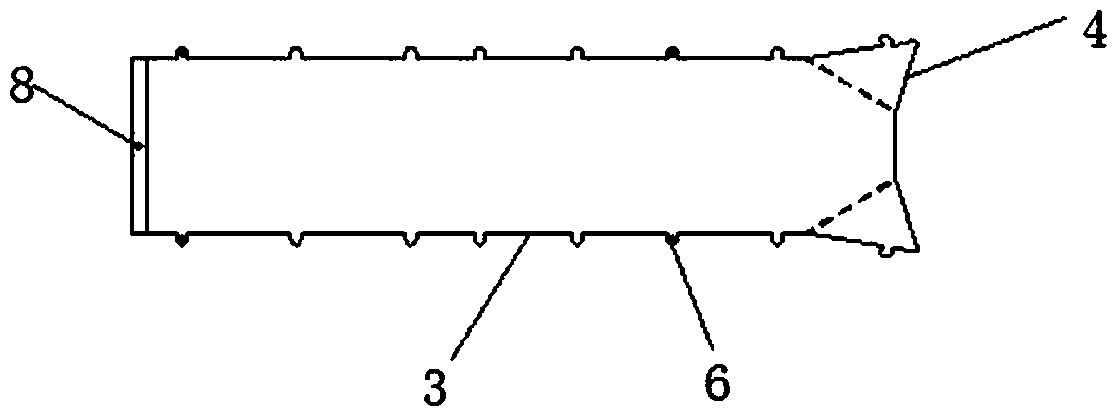

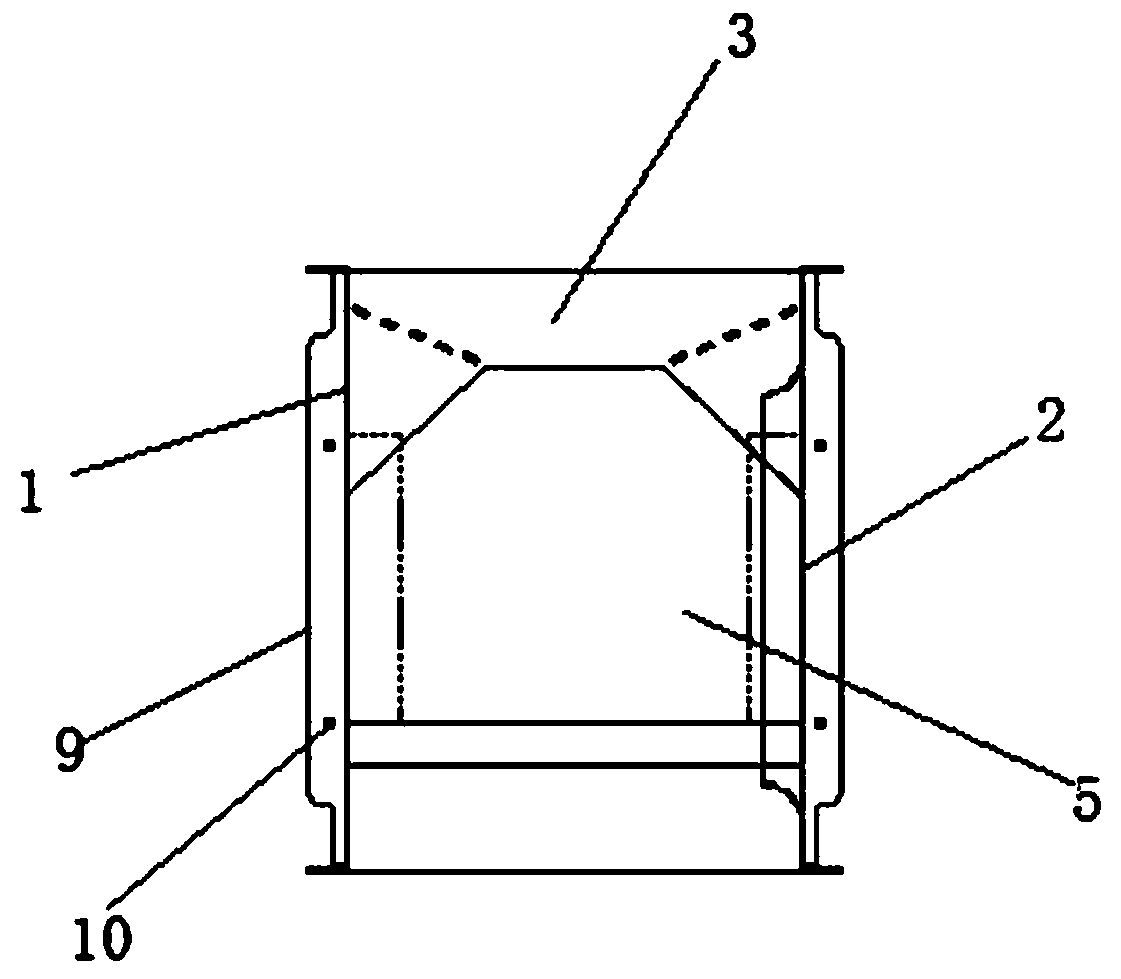

[0022] Such as Figure 1-3 Shown: a hexagonal volute, including a left side plate 1, a right side plate 2, and a wrapping plate 3 that is combined with the left side plate 1 and the right side plate 2 to form a volute. The wrapping plate 3 is bent into a It has a certain arc shape and is combined with the inner sides of the left side plate 1 and the right side plate 2 to form a volute. On the cladding plate 3, and located on the air outlet side of the volute, there is a folded structure 4. The folded structure 4 is installed with two protruding prongs, specifically two folded corners, and is symmetrically installed on the side of the cladding plate 3 with the central axis of the cladding plate 3 On the edge of the long and narrow notch 7, the edge is folded at an angle to match the assembly of the two side panels, so as to simplify the process and directly fold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com