Asphalt mixture rut monitoring device and method

A technology of asphalt mixture and monitoring device, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, and can solve the problem of heavy workload of rutting tests, large variability of test results, and instability of lateral flow deformation, etc. problem, to achieve the effect of reducing the workload of the experiment, the principle is simple and reliable, and the elimination of large variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

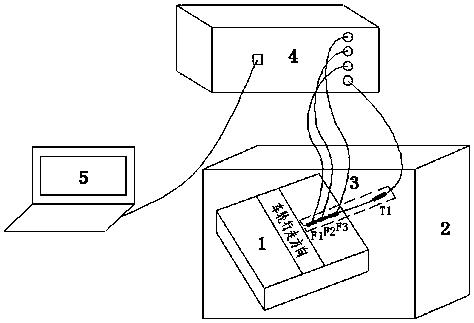

[0019] Such as figure 1 As shown, the monitoring device includes: rutting test piece 1, rutting tester 2, four surface-mounted FBG sensors 3, fiber grating demodulator 4 and monitoring terminal 5; rutting test piece 1 is set inside the rutting tester 2, and the FBG The sensor 3 is inside the rutting tester 2, and the FBG sensor 3 is connected to the fiber Bragg grating demodulator 4 through a fiber jumper, and the fiber Bragg grating demodulator 4 is connected to the monitoring terminal 5 through a data line. The four surface-mounted FBG sensors 3 include three FBG strain sensors F1, F2, F3 and a FBG temperature sensor T1, FBG strain sensors F1, F2, F3 are arranged continuously at equal intervals on the same straight line at the central area of the right surface of the rutting speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com