Micropore plate sampling system and method

A technology of microplate and moving mechanism, applied in the direction of analyzing materials, instruments, etc., can solve the problems of inability to guarantee consistency, time-consuming manual sample addition, cumbersome operation process, etc., to achieve slow solution efficiency, stable structure, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

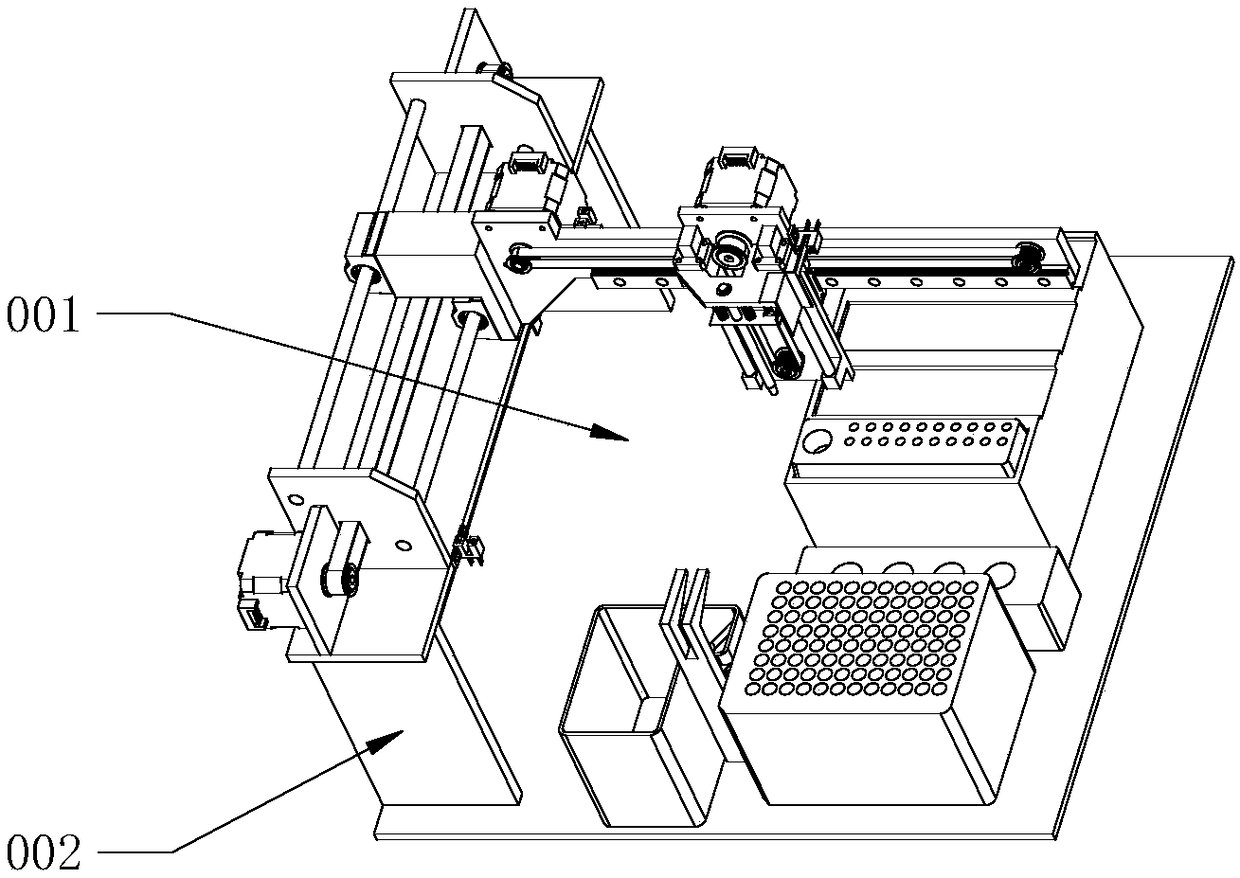

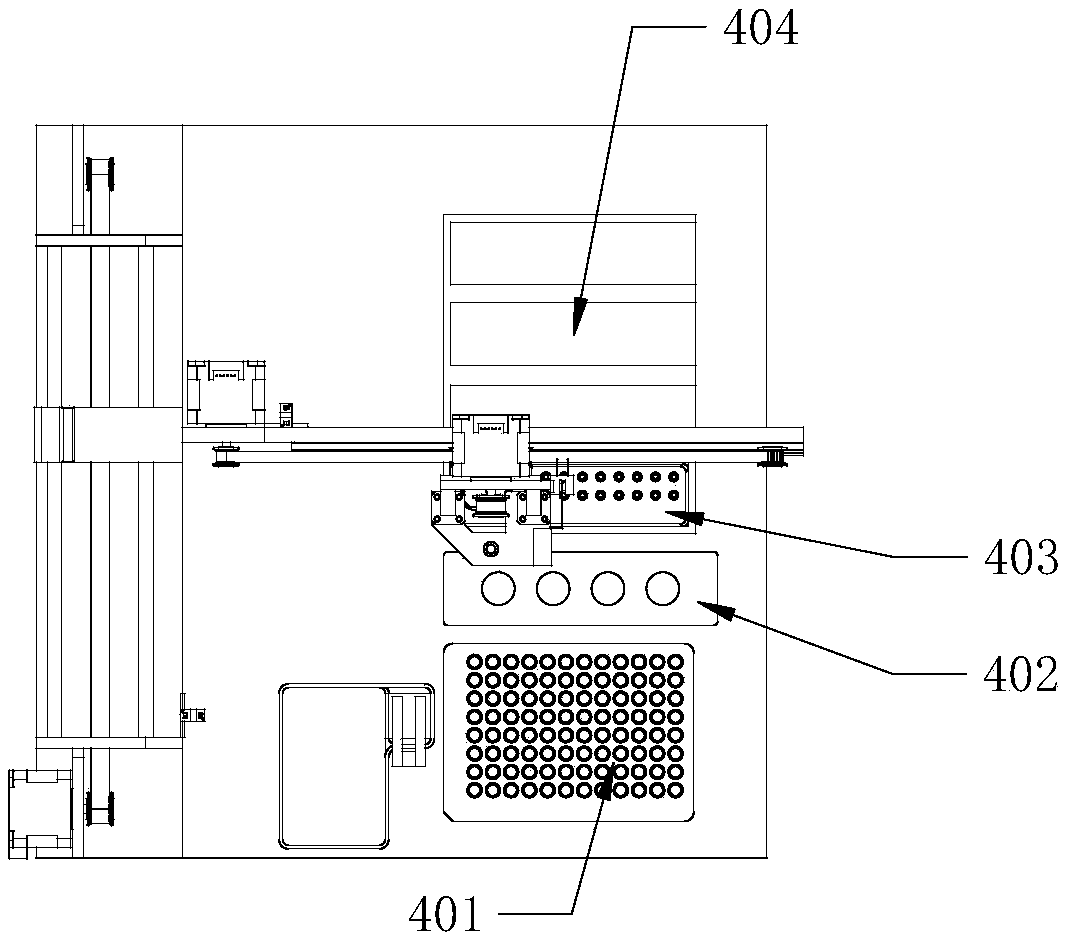

[0128] Example 1: Such as Figure 1-12 , A microplate sample adding system, including a base 001, a moving mechanism, a pipetting device, a waste processing device, a nozzle holder, a reagent holder 402, and a culture dish holder 404;

[0129] The moving mechanism, the waste processing device, the reagent rack and the culture dish rack are all arranged on the base; the pipetting device is arranged on the moving mechanism;

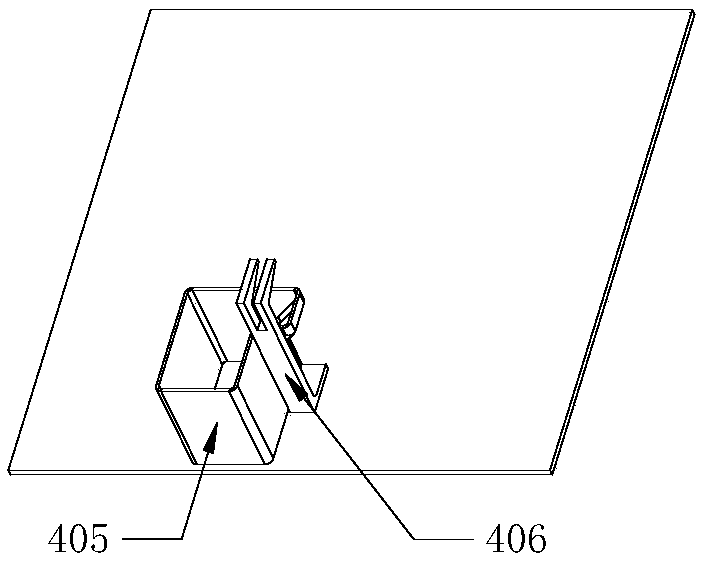

[0130] There are multiple suction nozzles 401 at the nozzle holder;

[0131] The reagent sets up multiple slots for placing test tubes;

[0132] At least one petri dish position is provided on the petri dish rack, and each petri dish position can place a petri dish 403 correspondingly;

[0133] The end of the pipetting device is provided with a suction needle 310 for loading a suction nozzle;

[0134] The moving mechanism is used to drive the pipetting device to switch between the positions of the waste processing device, the nozzle holder, the reagent holder and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com