PCR micro-reaction chamber array structure and method for packaging mixed liquid

A technology of micro-reaction chamber and array structure, applied in the direction of bioreactor/fermenter combination, laboratory container, chemical instrument and method, etc., can solve the problem of increasing the workload of operators, chip cost, up to tens of minutes to One hour, increase the workload of operators, etc., to achieve the effect of facilitating large-scale production, reducing supporting equipment and operation volume, and reducing bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

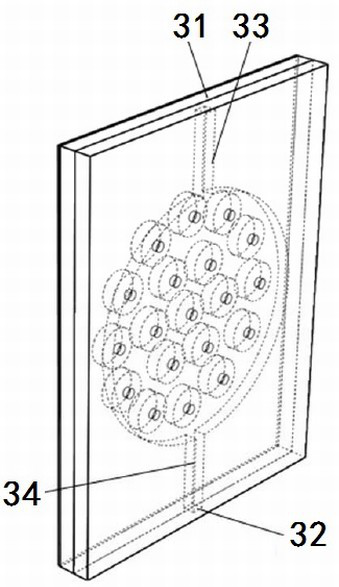

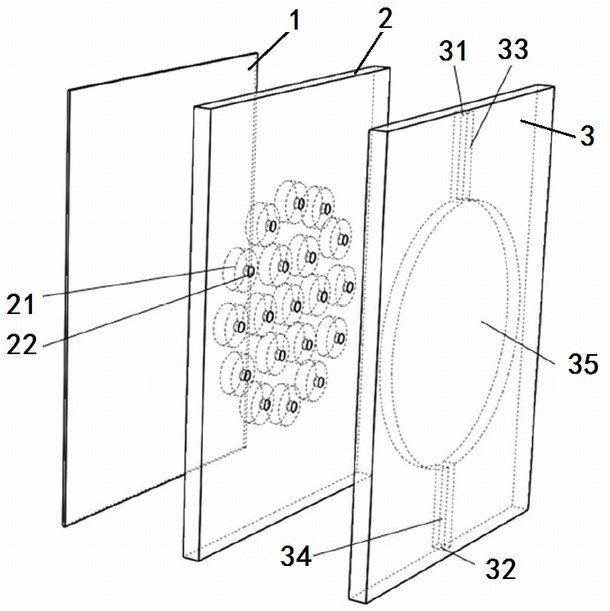

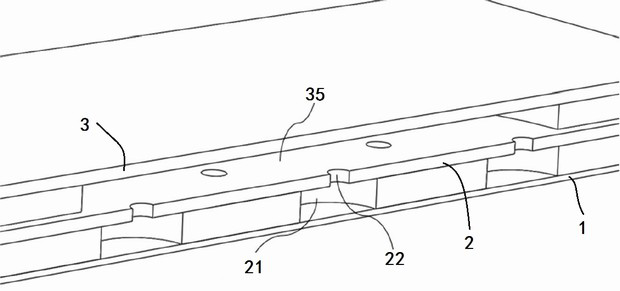

[0048] A kind of PCR microreaction chamber array structure, see figure 1 and figure 2 As shown, it is mainly composed of three layers: the bottom plate 1, the middle layer 2 and the cover plate 3, and the layers are bonded by heat sealing or glue. Such as image 3As shown, the middle layer 2 includes a micro-reaction chamber 21 and a throat 22, and the micro-reaction chamber 21 and the throat 22 are integrally injection-molded, and there is no bonding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com