Test device, test method, computer device and computer readable storage medium

A technology of computer equipment and testing equipment, which is applied in the field of testing, can solve problems affecting production speed, terminal looseness, test false alarms, etc., and achieve the effects of improving production efficiency, avoiding terminal loosening, and reducing the probability of component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

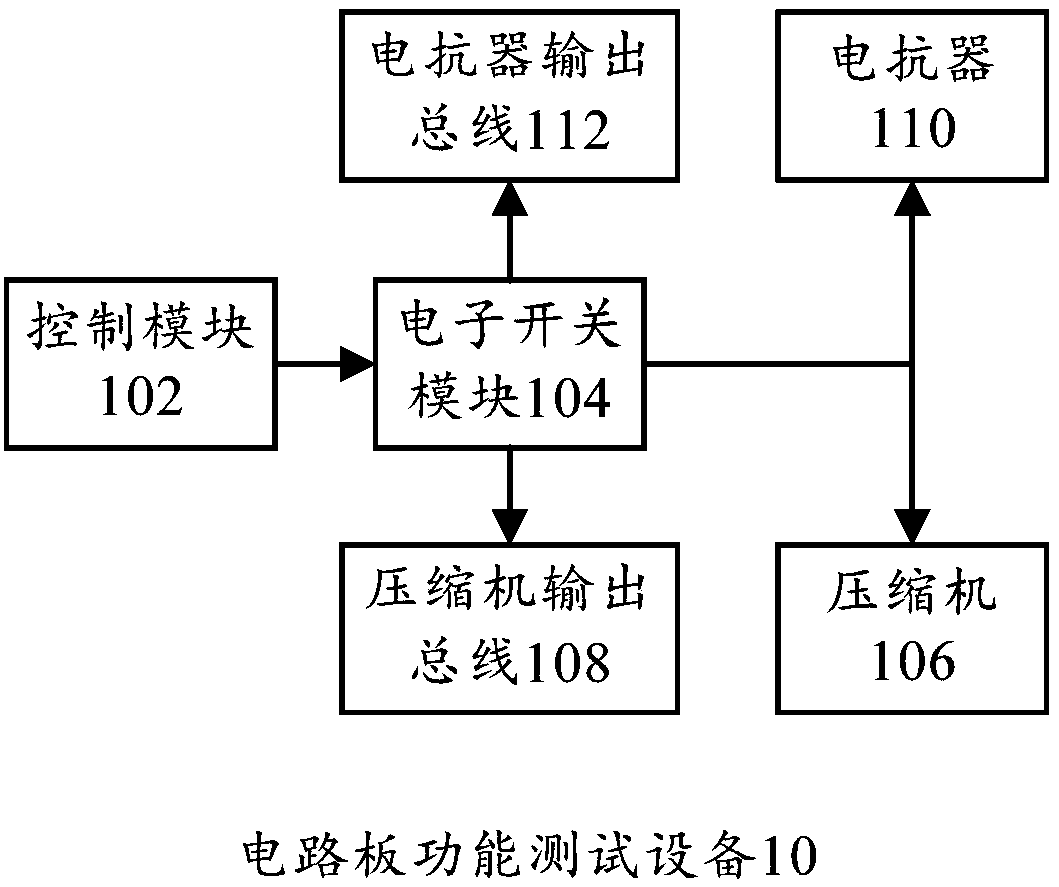

[0058] In any of the above embodiments, preferably, the control connection port includes a voltage output pin and a plurality of I / O pins, the voltage output pin is used to output 24V voltage; the electronic switch is a relay, and the first group of electronic switches is the second A group of relays, the second group of electronic switches is the second group of relays, the electronic switch module includes: a row of parallel relays, the first end of each relay is respectively connected to the voltage output pin, the second end of each relay is respectively connected to Multiple I / O pins are connected correspondingly. The third terminal of the first group of relays is respectively connected to the compressor output bus, the fourth terminal of the first group of relays is respectively connected to multiple compressors of different models, and the first The three terminals are respectively connected to the reactor output bus, and the fourth terminals of the second group of relay...

Embodiment 2

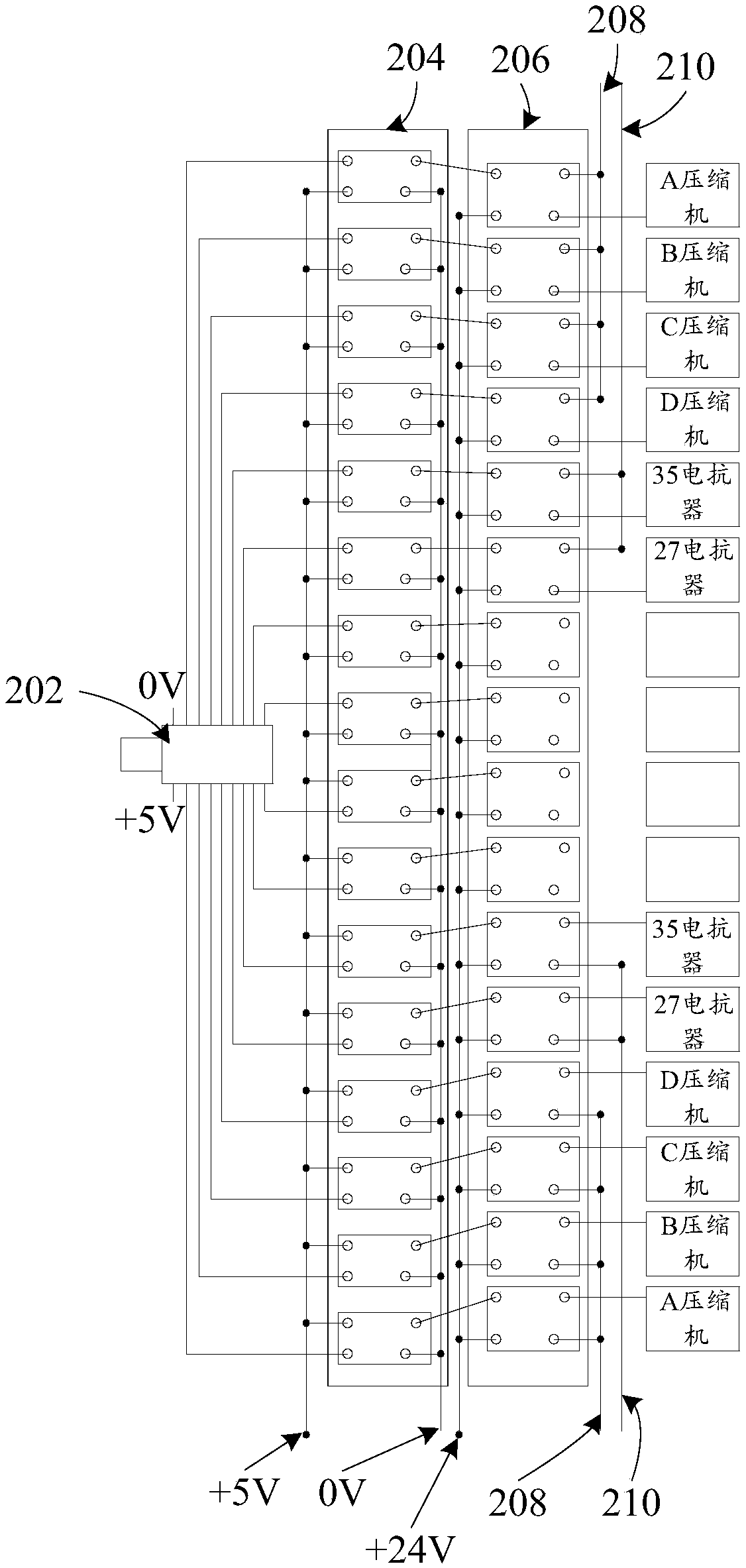

[0062] Such as figure 2As shown, in any of the above embodiments, preferably, the control connection port 202 includes a voltage output pin and a plurality of I / O pins, and the voltage output pin is used to output 5V voltage; the electronic switch is a relay, and the first group The electronic switch is the first group of relays, the second group of electronic switches is the second group of relays, the electronic switch module includes: the first row of relays 204 and the second row of relays 206, the first end of each relay in the first row of relays 204 respectively connected to the voltage output pins, the second end of each relay in the first row of relays 204 is respectively connected to a plurality of I / O pins, and the third end of each relay in the first row of relays 204 is grounded; The air conditioner detection equipment also includes: a power supply for outputting 24V voltage; the second row of relays 206 includes a first group of relays and a second group of rela...

Embodiment 3

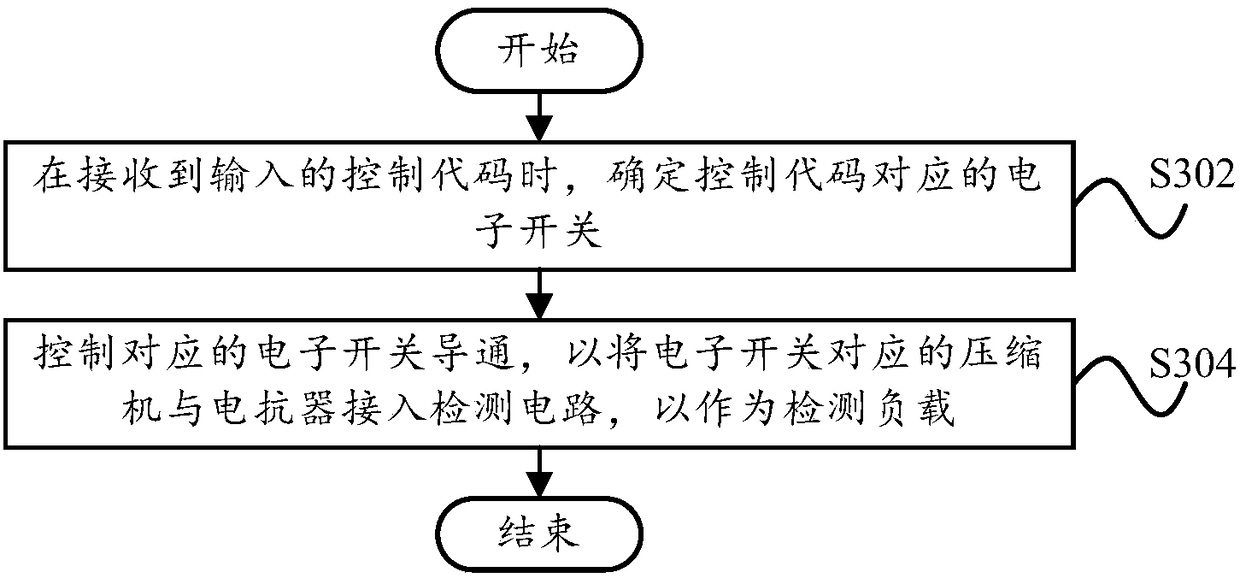

[0073] Such as image 3 As shown, the circuit board function testing method according to an embodiment of the present invention includes: step 302, when receiving the input control code, determine the electronic switch corresponding to the control code; step 304, control the corresponding electronic switch to conduct, The compressor and reactor corresponding to the electronic switch are connected to the detection circuit as the detection load.

[0074] In this embodiment, by receiving the control code input by the user, the I / O pin corresponding to the control code is determined to further determine the electronic switch connected to the I / O pin, and by controlling the connection of the corresponding electronic switch, the electronic The switch-controlled compressor is connected to the detection circuit to detect whether the control circuit board can operate normally. The control module controls the on-off of the electronic module in the electronic switch module to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com