Ultrasonic touch apparatus and manufacturing method thereof

A technology of a touch device and a manufacturing method, which is applied in the direction of instruments, electrical digital data processing, and input/output processes of data processing, etc., can solve the problems that conductive glue and conductive pins cannot be electrically connected normally, so as to avoid tolerance accumulation, Effect of avoiding tolerance and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

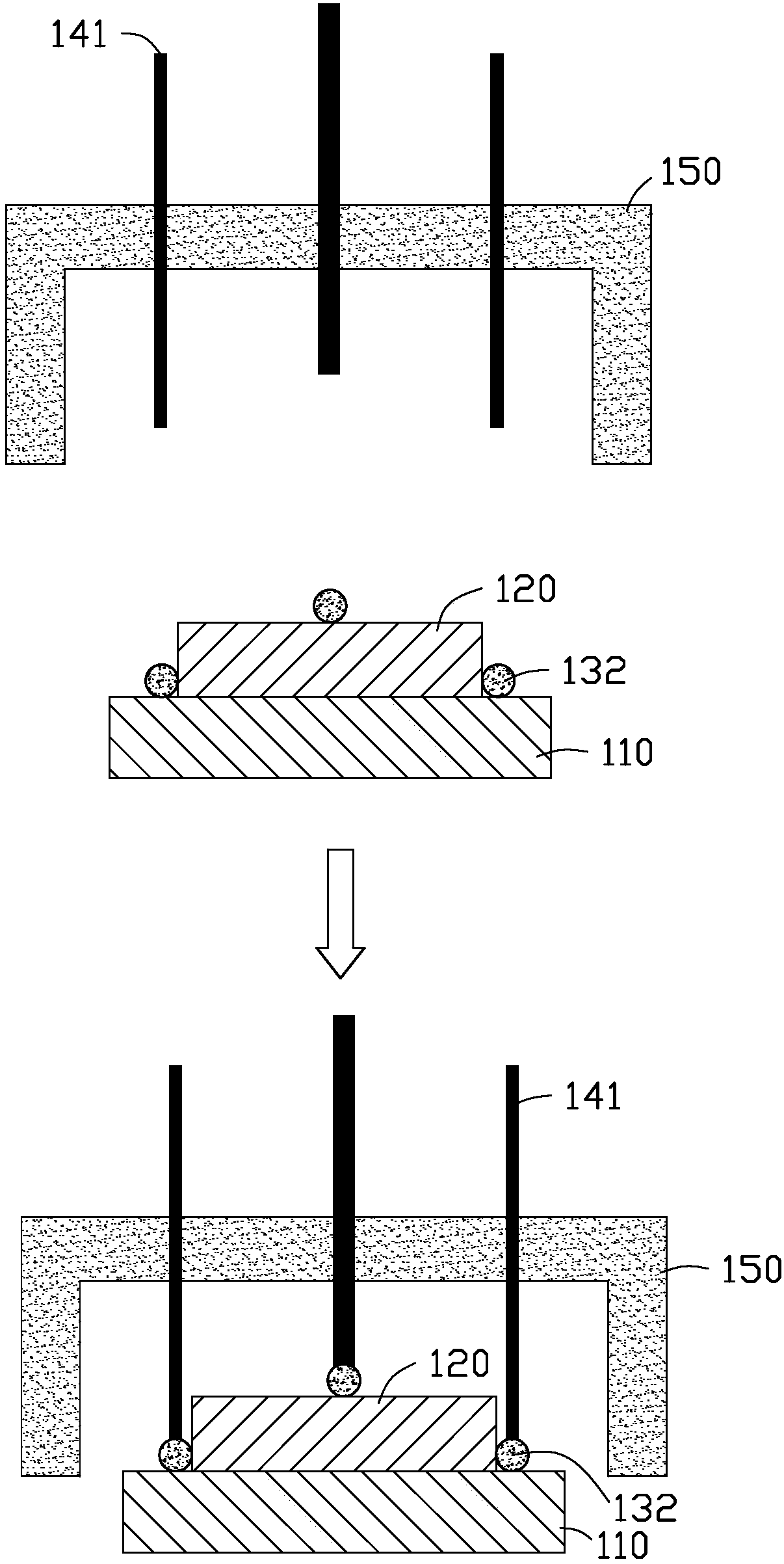

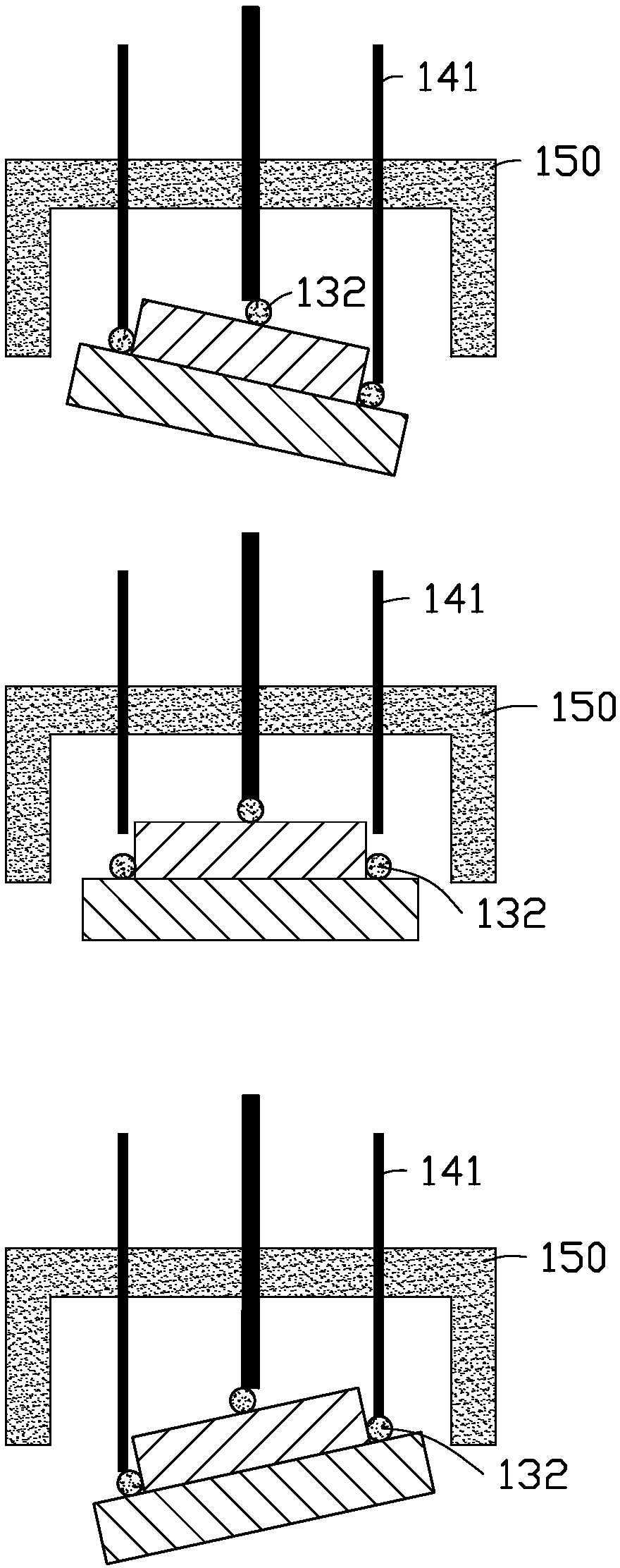

[0025] The manufacturing method of the ultrasonic touch device according to the preferred embodiment of the present invention includes the following steps:

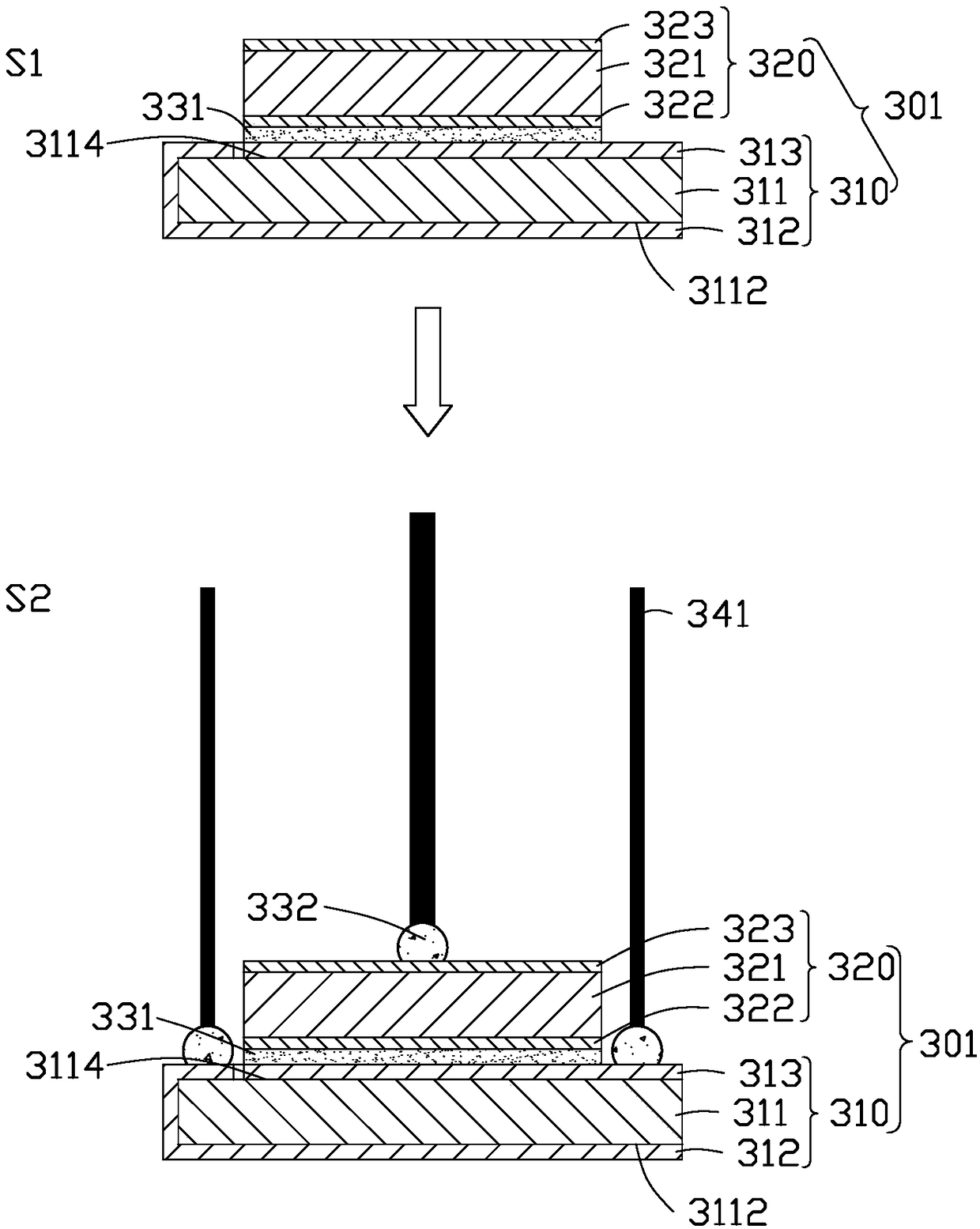

[0026] see Figure 3A , Step S1: providing an ultrasonic sensing module 301, the ultrasonic sensing module 301 includes an ultrasonic transmitting unit 310 and an ultrasonic receiving unit 320 arranged in a stack.

[0027] The ultrasonic emitting unit 310 includes a first piezoelectric sheet 311 , a first electrode 312 and a second electrode 313 . The first electrode 312 completely covers a first surface 3112 of the first piezoelectric sheet 311 and extends from the first surface 3112 to a second surface 3114 opposite to the first surface 3112, and the second electrode 313 is disposed on the second surface. On the surface 3114 , the second electrode 313 is not in contact with the first electrode 312 . The ultrasonic receiving unit 320 includes a second piezoelectric sheet 321 and a third electrode 322 and a fourth elect...

no. 2 example

[0049] Such as Figure 5 As shown, is a schematic structural diagram of the ultrasonic touch device 600 manufactured by the method for manufacturing the ultrasonic touch device.

[0050] The ultrasonic touch device 600 includes an ultrasonic sensing module 601 , conductive pins 641 , packaging glue 650 and a cover 660 .

[0051] The ultrasonic sensing module 601 includes an ultrasonic transmitting unit 610 and an ultrasonic receiving unit 620 . The ultrasonic emitting unit 610 includes a first piezoelectric sheet 611 , a first electrode 612 and a second electrode 613 . The first electrode 612 completely covers a first surface 6112 of the first piezoelectric sheet 611 and extends from the first surface 6112 to a second surface 6114 opposite to the first surface 6112. The second electrode 613 is arranged on the same side as the first electrode. 612 Completely covered surface opposite surface such as Figures 6A-6B As shown, on the surface where the first electrode 612 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com