A flywheel energy storage array and its energy balance control method

A flywheel energy storage and array technology, applied in the direction of AC network load balancing, can solve the problems of low efficiency and reliability, high system cost, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

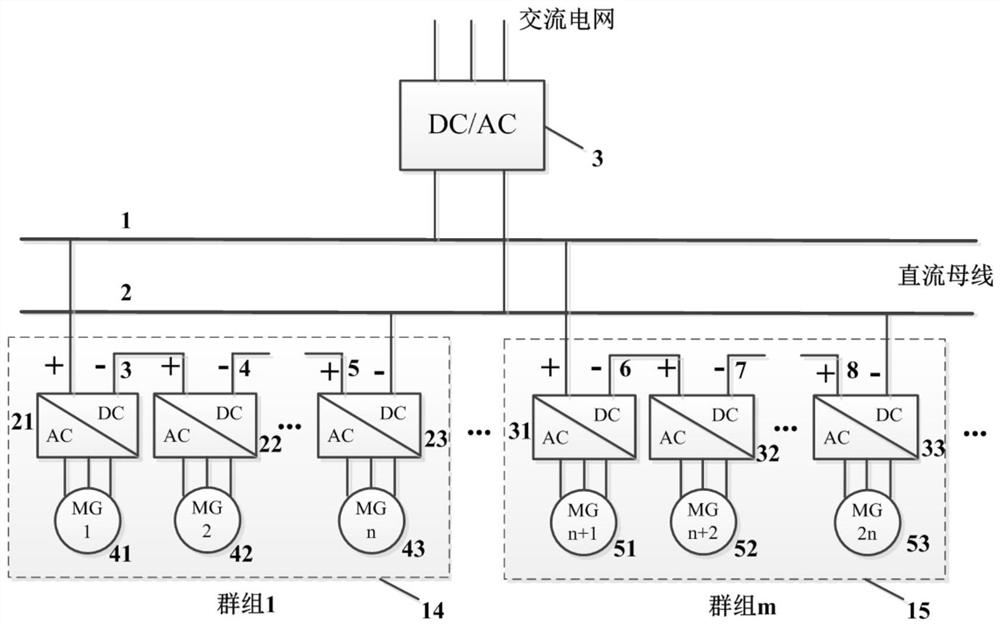

[0036] figure 1 Shown is Example 1 of the present invention. Such as figure 1 As shown, a flywheel energy storage array of the present invention is composed of the first grid-side bidirectional DC / AC converter 3, the first flywheel group 14 and the mth flywheel group 15; the first flywheel group 14 consists of the first Flywheel motor 41, second flywheel motor 42, nth flywheel motor 43, first machine side bidirectional DC / AC converter 21, second machine side bidirectional DC / AC converter 22, nth machine side bidirectional DC / AC converter 23; the mth flywheel group 15 consists of the n+1th flywheel motor 51, the n+2th flywheel motor 52, the 2nth flywheel motor 53, the n+1th machine-side bidirectional DC / AC converter 31, the n+2th It consists of a machine-side bidirectional DC / AC converter 32 and a 2nth machine-side bidirectional DC / AC converter 33 .

[0037] The first lead-out terminal, the second lead-out terminal and the third lead-out terminal of the first grid-side bidir...

Embodiment 2

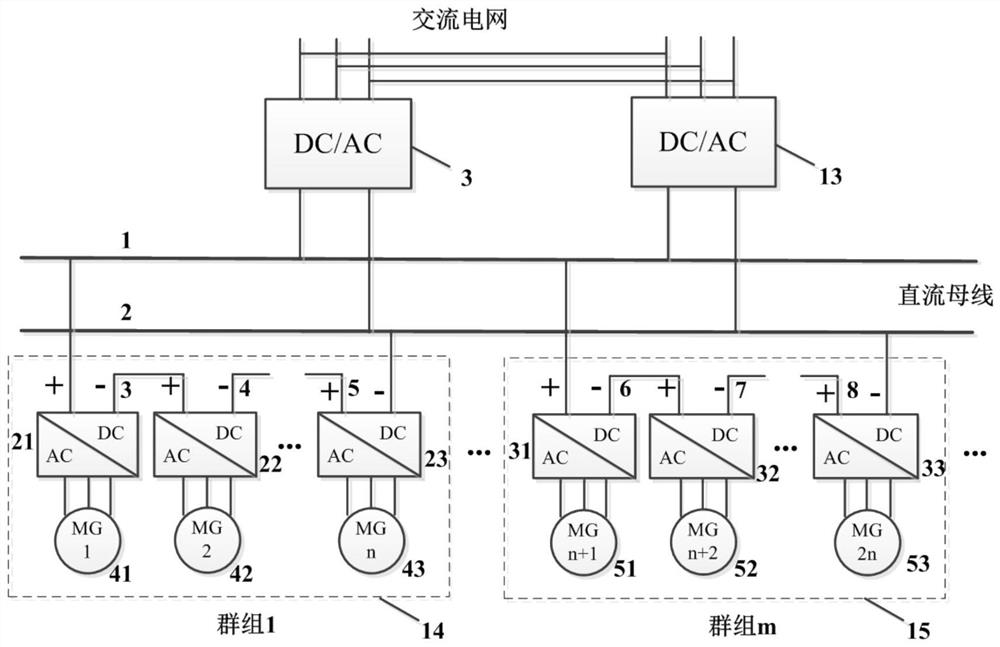

[0044] figure 2 Shown is Example 2 of the present invention. Such as figure 2 As shown, the flywheel energy storage array of the present invention is composed of a first grid-side bidirectional DC / AC converter 3, a second grid-side bidirectional DC / AC converter 13, a first flywheel group 14 and an mth flywheel group 15; The first flywheel group 14 is composed of a first flywheel motor 41, a second flywheel motor 42, an nth flywheel motor 43, a first machine-side bidirectional DC / AC converter 21, a second machine-side bidirectional DC / AC converter 22, a The n machine side bidirectional DC / AC converter 23 is composed; the mth flywheel group 15 is composed of the n+1th flywheel motor 51, the n+2th flywheel motor 52, the 2nth flywheel motor 53, and the n+1th machine side bidirectional DC / AC converter It is composed of an AC converter 31, an n+2th machine-side bidirectional DC / AC converter 32, and a 2nth machine-side bidirectional DC / AC converter 33.

[0045]The first lead-out...

Embodiment 3

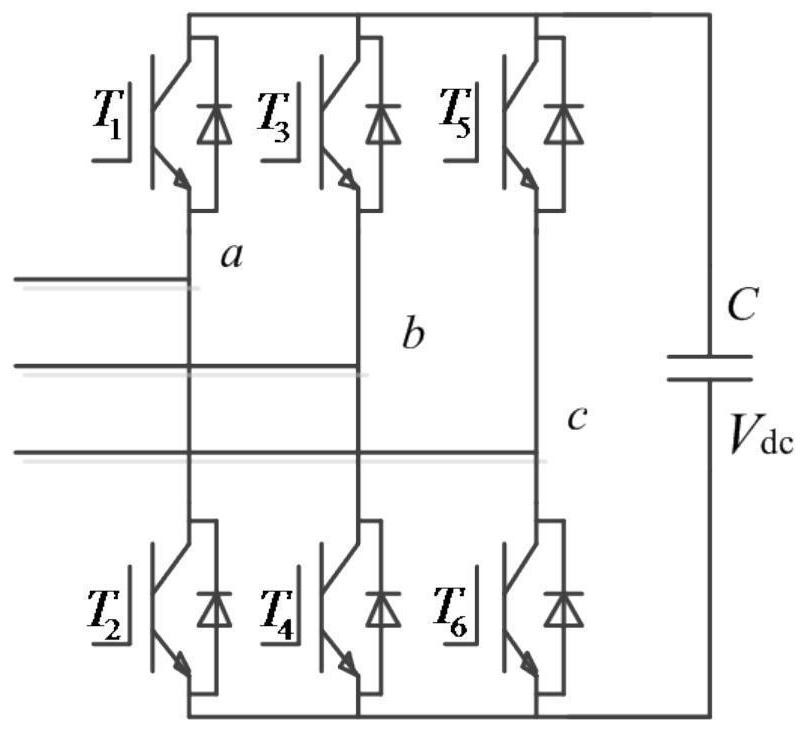

[0048] image 3 , Figure 4 and Figure 5 Shown is Example 3 of the present invention. Such as image 3 , Figure 4 and Figure 5 As shown, in the flywheel energy storage array of the present invention, the first grid side bidirectional DC / AC converter 3, the second grid side bidirectional DC / AC converter 13, the first machine side bidirectional DC / AC converter 21, the second machine side side bidirectional DC / AC converter 22, nth machine side bidirectional DC / AC converter 23, n+1th machine side bidirectional DC / AC converter 31, n+2th machine side bidirectional DC / AC converter 32, and 2n The machine-side bidirectional DC / AC converter 33 can all adopt a two-level structure, a mid-point embedded three-level structure and a modular multi-level structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com