Parallel wind power converter system, control method, wind power unit

A technology of wind power converters and electric converters, applied in wind power generation, electrical components, circuit devices, etc., which can solve problems such as interruption of operation due to shutdown switching, affecting efficiency, and the system does not meet the requirements of reactive power support. The effect of optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

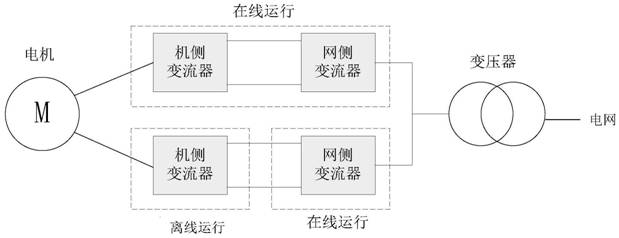

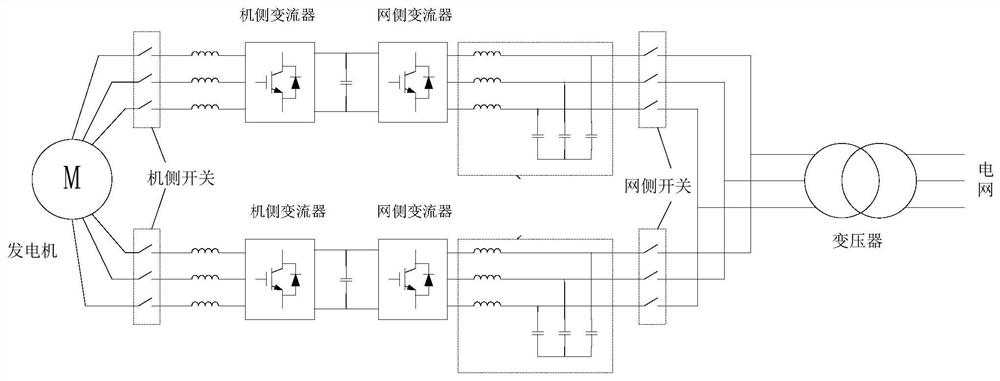

[0076] Taking a 5.0MW offshore wind turbine as an example, it is set as a double-winding 2 wind power converter, that is, two wind power converters are connected in parallel, and the control group method is as follows:

[0077] When the unit starts to run, the grid-side converters of the two wind power converters are turned on first; when the wind speed is low, only the machine-side converter of one wind power converter is turned on, and the other wind power The side converter is in standby mode (such as figure 2 Shown), in order to reduce the converter loss.

[0078] When the wind speed increases and the power generation increases, if it is necessary to increase the number of single units (wind power converters) that are put into operation through the input logic calculation, the machine-side converter of the other wind power converter that was originally in the standby state is put into operation. running, and the torque reference gradually increases from 0 to half of the ...

Embodiment 2

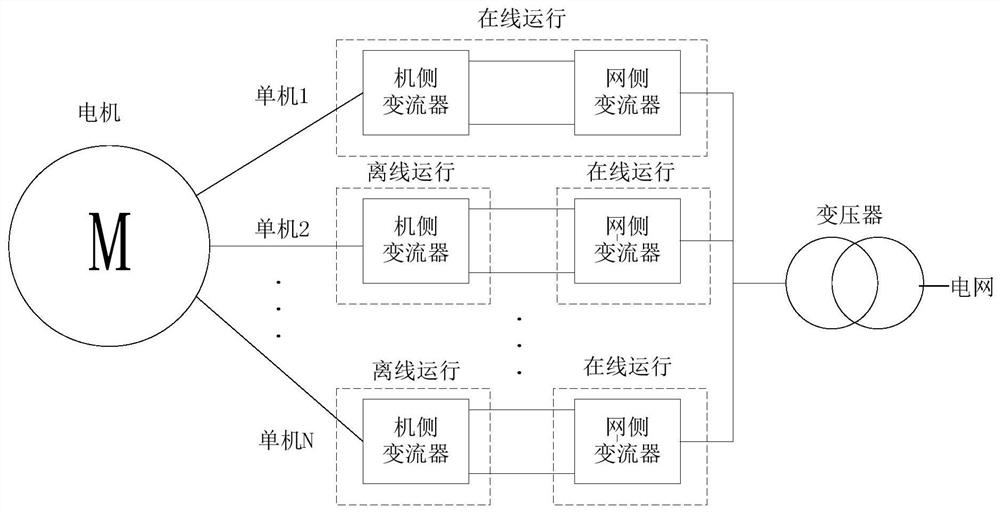

[0081] Take a 6MW wind turbine with 4 windings and 4 converters as an example, that is, 4 wind power converters are connected in parallel, and the power of each wind power converter is 1.5MW (Note: 4 wind power converters are completely consistent), Its operating mode is as follows:

[0082] When the unit is started and running, the grid-side converters of four wind power converters are turned on first; when the wind speed is low, only the machine-side converter of one wind power converter is turned on, and the machine-side converters of the other three wind power converters are turned on. The converter is in a standby state to reduce converter losses.

[0083] When the wind speed increases and the power generation increases, if it is necessary to increase the number of single units (wind power converters) that are put into operation through the input logic calculation, the machine-side converter of one of the wind power converters that was originally in the standby state is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com