Metal fiber-based special high-temperature-resistant flue gas dust removal filter felt and preparation method thereof

A metal fiber and filter felt technology, which is applied in the field of metal fiber-based special high-temperature-resistant flue gas dust removal filter felt and its preparation, can solve problems such as high temperature, and achieve the effects of reducing fiber damage, entanglement and fastening, and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

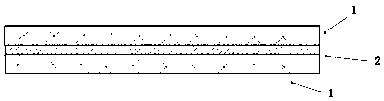

[0026] figure 1 A schematic structural diagram of an embodiment of the present invention is shown, figure 2 A schematic diagram of the metal fiber substrate of the present invention is shown. like figure 1 As shown, the present invention provides a metal fiber-based special high-temperature-resistant flue gas dust removal filter felt. Heat setting treatment to reinforce the composite filter felt.

[0027] The present invention also provides a metal fiber-based special high-temperature-resistant flue gas dust removal filter felt. Reinforced composite filter felt.

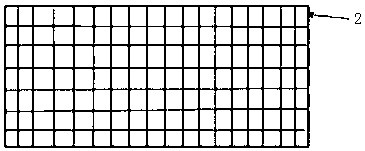

[0028] like figure 2 As shown, the metal fibers in the metal fiber substrate 2 are stainless steel metal materials, or copper fiber metal materials. The metal fiber base material 2 is a middle support layer composed of metal fiber crisscross woven diameter net, which is used to sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com