Production equipment used for putty

A production equipment and putty technology, applied in the direction of dissolution, mixer, chemical equipment and methods, etc., can solve the problems of uneven mixing of putty, achieve the effect of changing the mixing range, stirring evenly, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

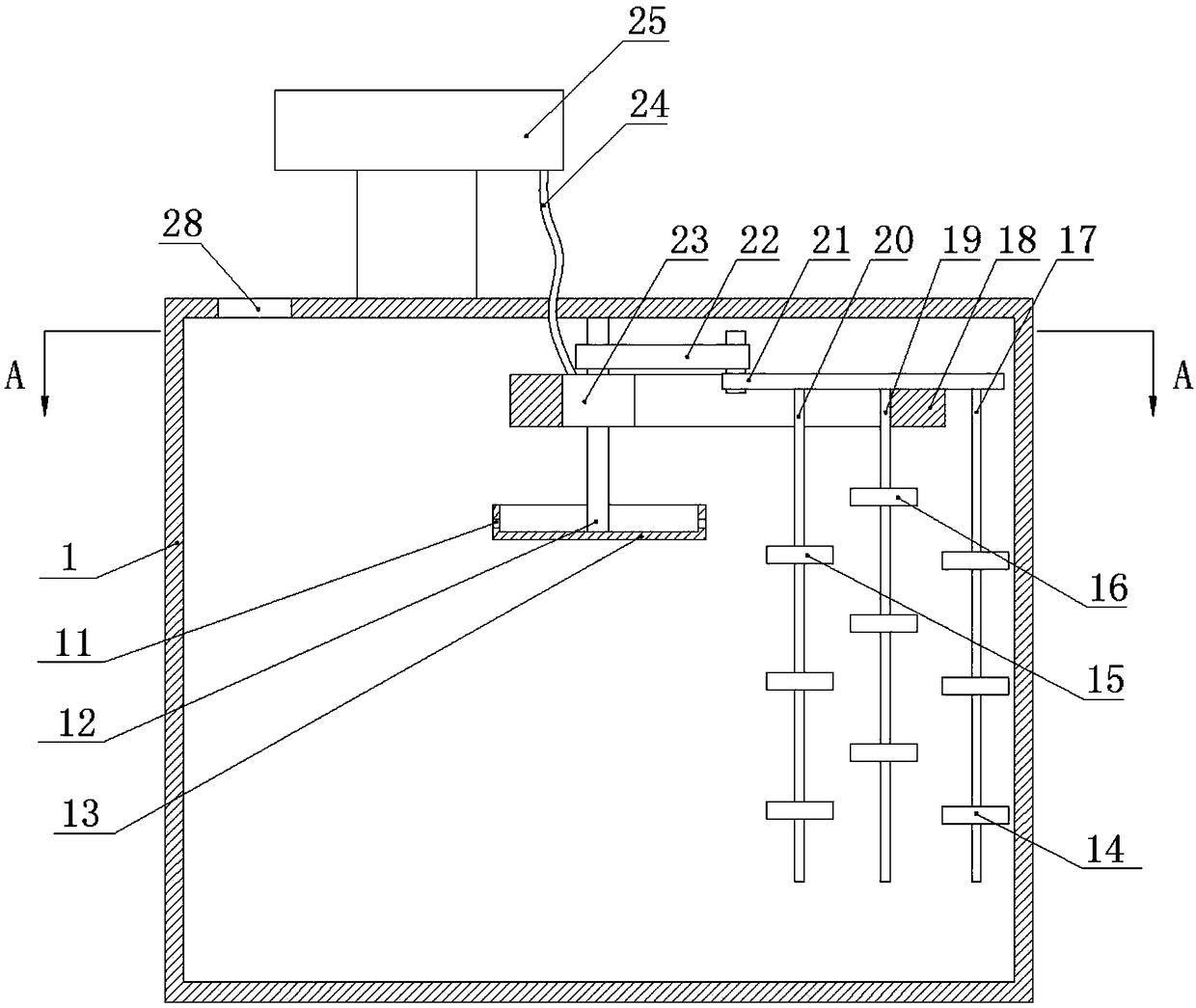

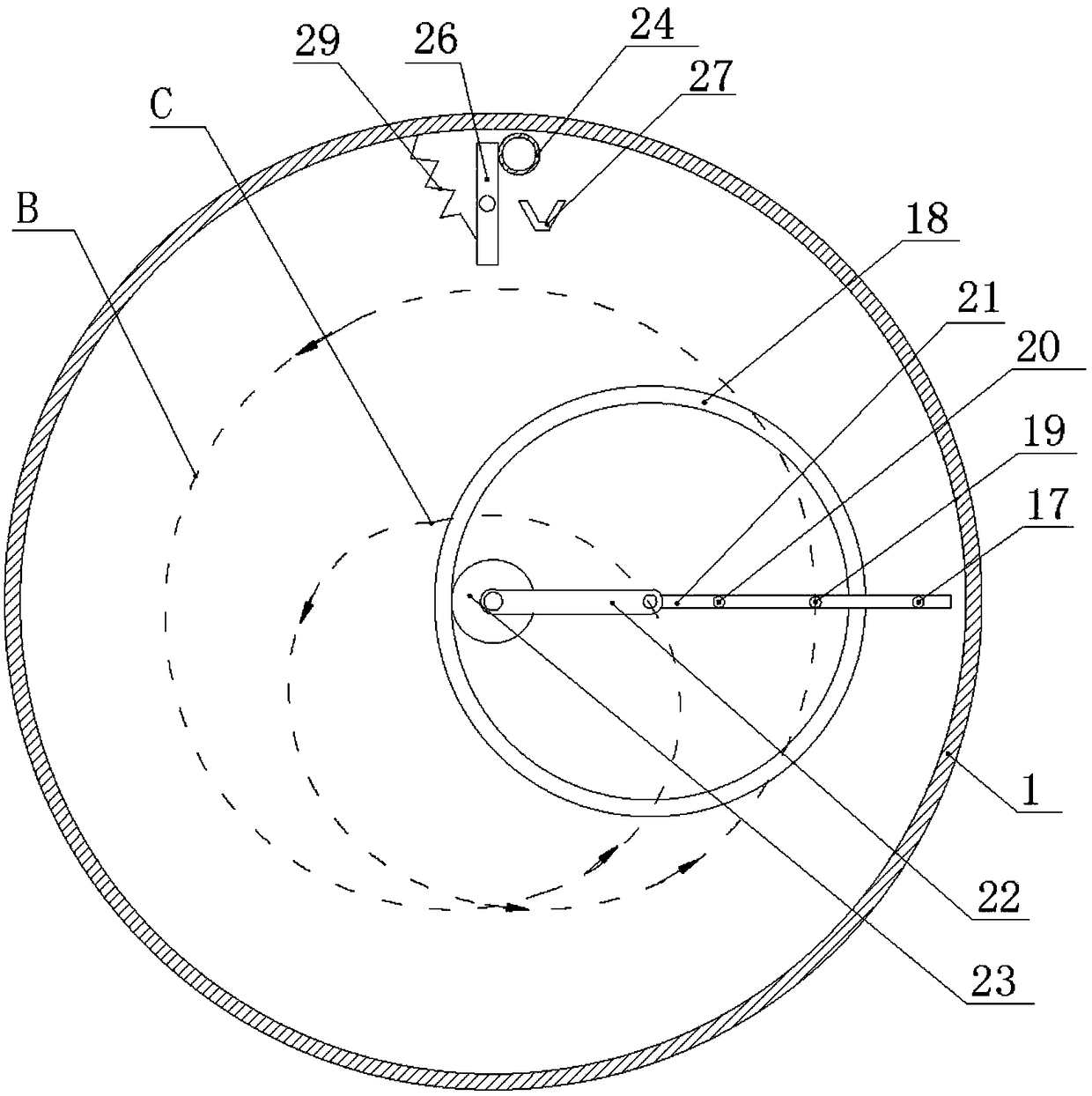

[0020] The reference signs in the accompanying drawings of the description include: mixing bucket 1, sprinkling hole 11, rotating shaft 12, sprinkling cylinder 13, third stirring blade 14, first stirring blade 15, second stirring blade 16, third stirring shaft 17, teeth Circle 18, the second stirring shaft 19, the first stirring shaft 20, connecting rod 21, crank 22, gear 23, flexible pipe 24, water tank 25, lever 26, water stop clip 27, feeding port 28, spring 29.

[0021] figure 2 Curve B in the middle is the movement trajectory of the second stirring shaft 19 , point C is the starting point of the movement of the second stirring shaft 19 , and the arrow indicates the moving direction of the second stirring shaft 19 .

[0022] like figure 1 and figure 2 As shown, the production equipment for putty of the present invention comprises a mixing tank 1, and the left end of the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com