A flexible mesh belt type air suspension tea sorting equipment

A technology of air suspension and flexible net, which is applied in the field of agricultural machinery, can solve problems such as uneven defects, increased costs, and different processing techniques, and achieve the effects of low speed, reduced damage, and reduced screening loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

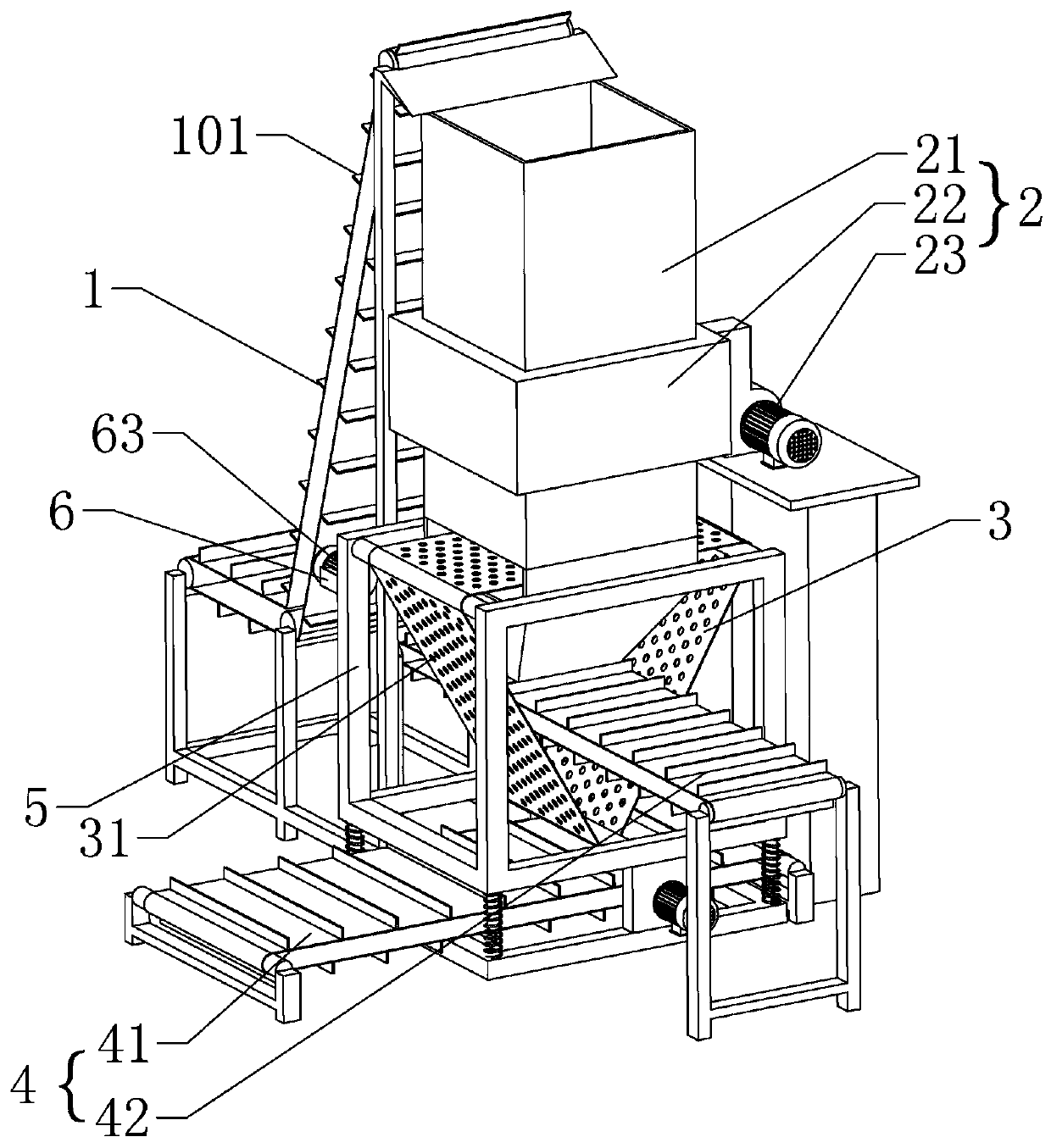

[0032] according to Figure 1 to Figure 5 As shown, a flexible mesh-belt type air-suspension tea sorting device includes: a lifting part 1, an air-suspension part 2, a flexible mesh-belt sorting part 3 and an output part 4.

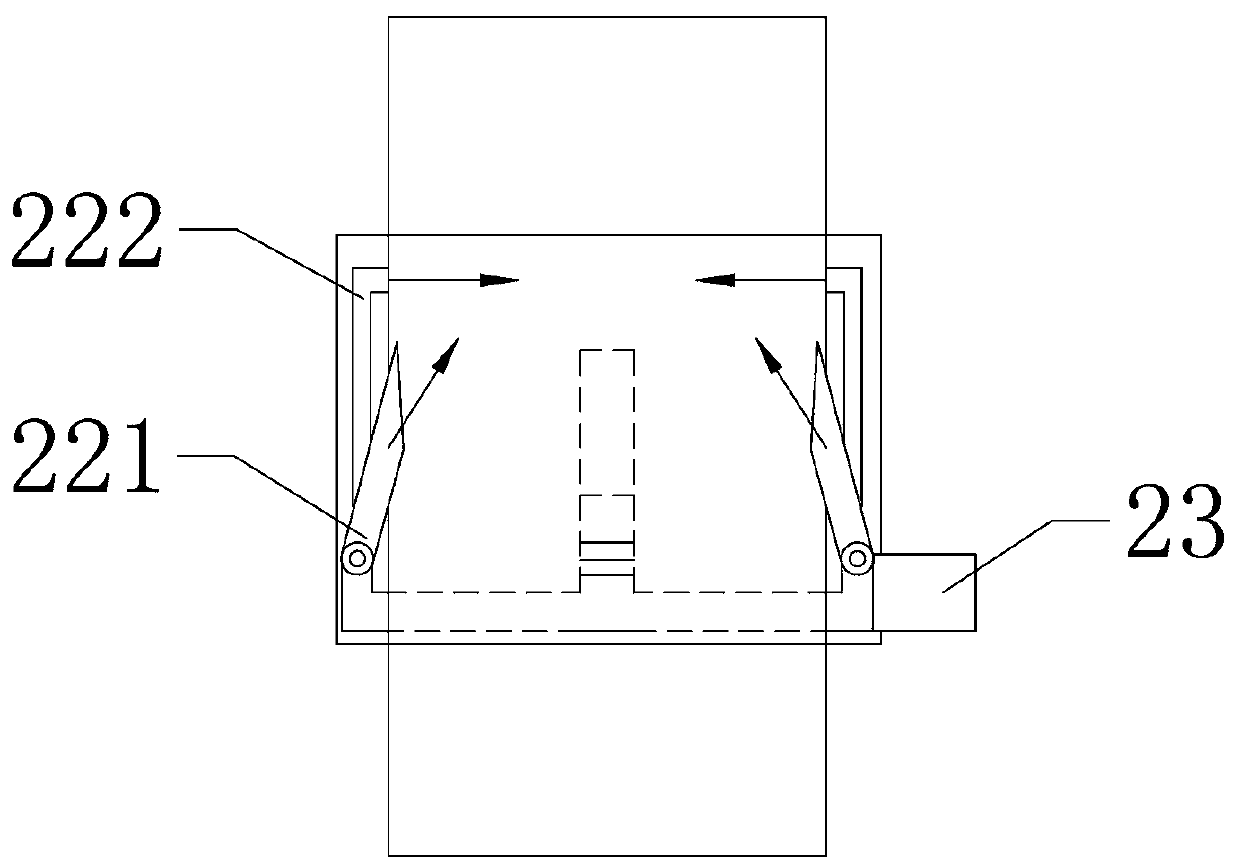

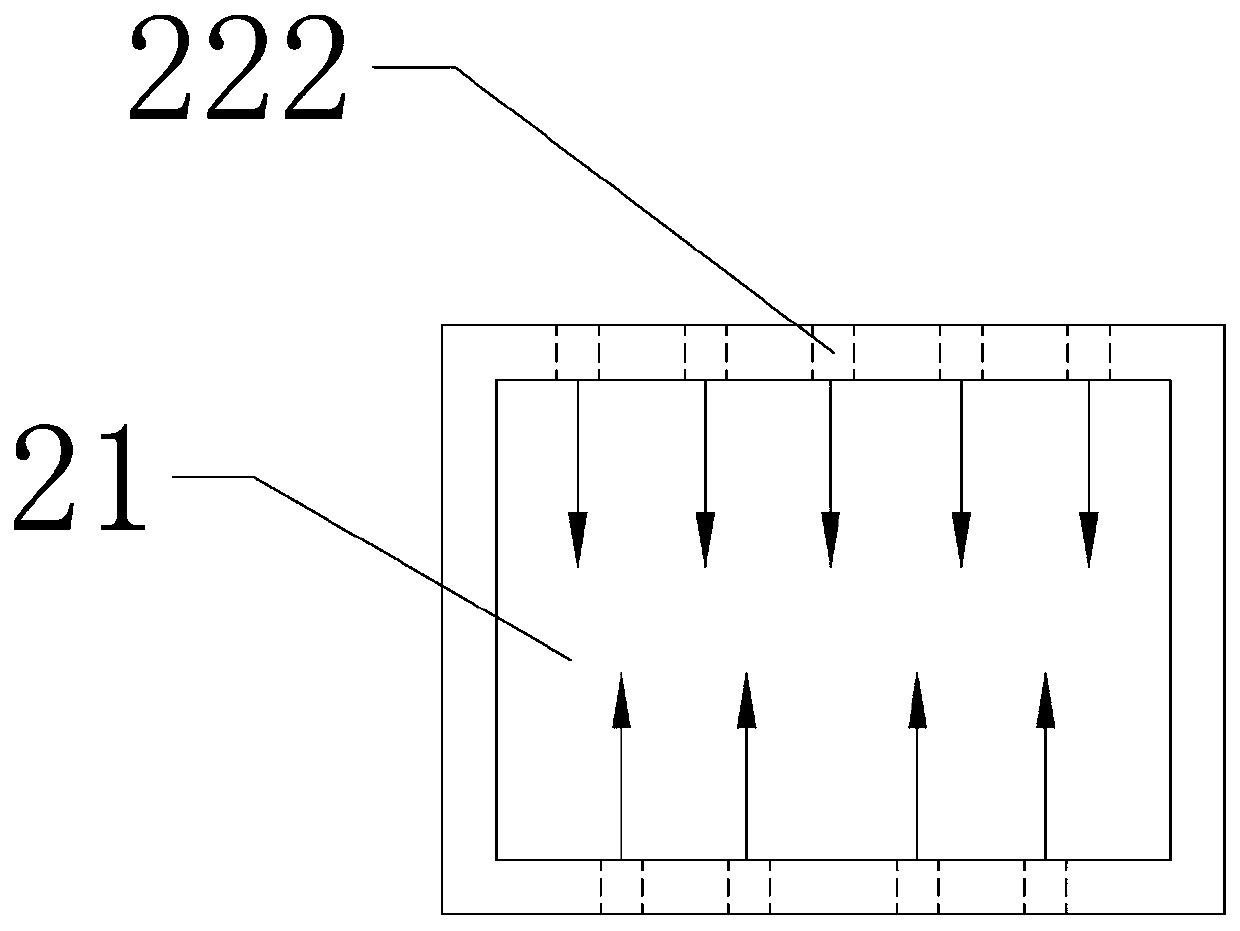

[0033] according to figure 2 , image 3 As shown, the air suspension component 2 includes a drop channel 21, an air suspension air channel 22 and an air suspension fan 23, the drop channel 21 is vertically arranged, the flexible mesh belt sorting component 3 is arranged under the drop channel 21, and the air suspension air channel 22 The air outlet is arranged on the side wall of the drop channel 21 , and the air inlet of the air suspension duct 22 is connected with the air suspension fan 23 .

[0034] Air suspension air channel 22 comprises, slow speed air channel 221 and dispersion air channel 222, and dispersion air channel 222 is arranged on the top of slow speed air channel 221; The air ducts are hinged so that the blowing angle can be adjusted; ...

Embodiment 2

[0042] The difference from the above-mentioned embodiment 1 is that, according to the Figure 6 As shown, the flexible mesh belt 31 includes a sieving mesh surface 311 and three separating mesh surfaces 312, the sieving mesh surface 311 and the separating mesh surface 312 are equal in length, so that the whole flexible mesh belt 31 forms a square ring, and the sieving mesh surface 311 is arranged on the top of the entire ring, and the square flexible mesh belt 31 makes the space in the flexible mesh belt 31 ring larger, thereby facilitating the outer blowing pipe 7 and the thin leaf output belt 42 to have a larger space for placement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com