Control method, modular joint robot and storage medium

A control method and robot technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of difficult programming learning and high learning threshold, and achieve the effect of low learning threshold, lower development threshold and low design cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

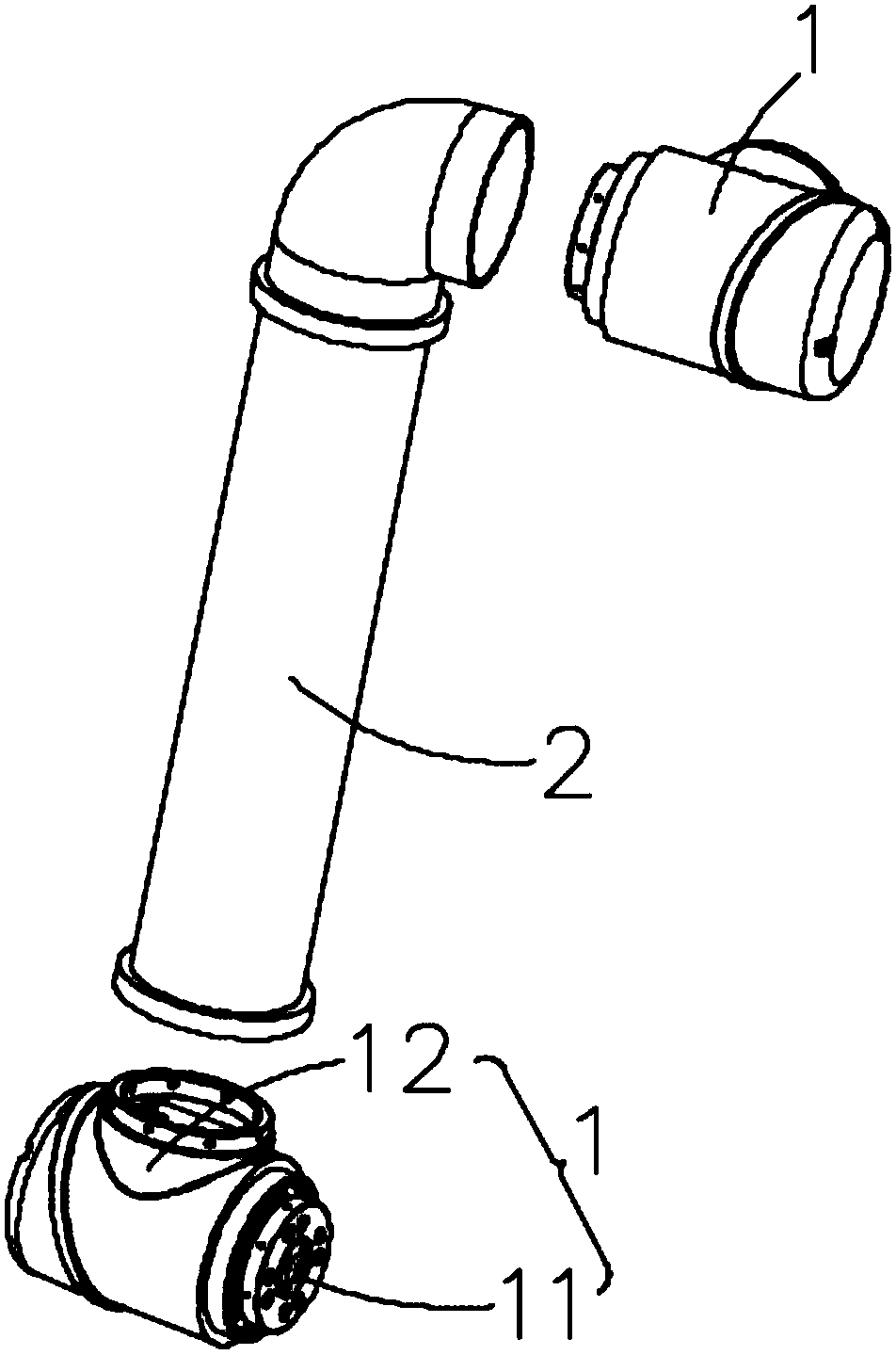

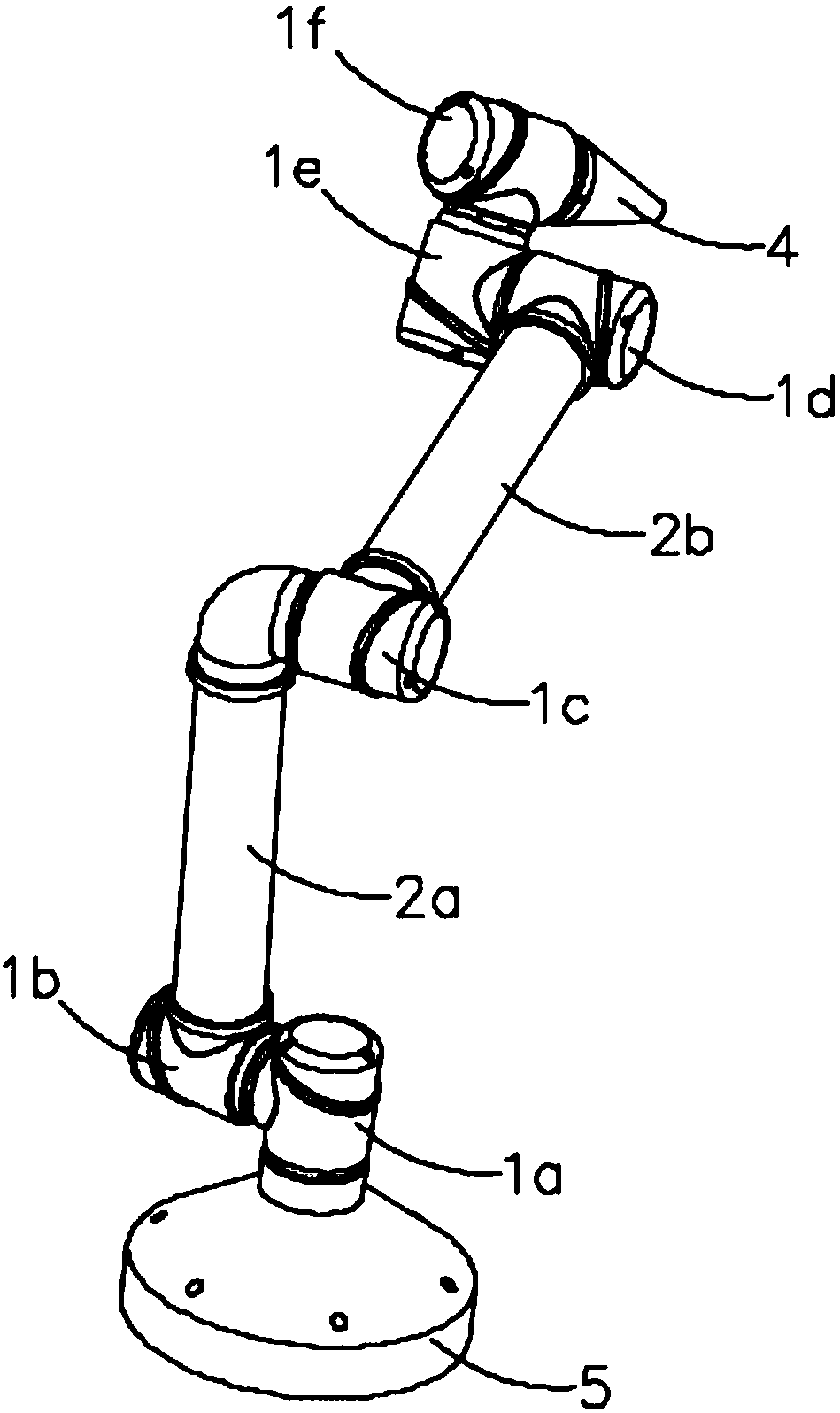

[0025] Such as Figure 1 to Figure 4 As shown, a modular articulated robot is provided in this embodiment, including a plurality of articulated arms 2, a plurality of articulated modules 1, and a control system 3; wherein, the articulated module 1 is installed at the end of the articulated arm 2 for driving two Adjacent articulated arms 2 relatively swing.

[0026] The joint module 1 includes a fixing base 12 , a motor installed in the fixing base 12 and an output shaft 11 . The joint module 1 can be installed in various ways, for example, the fixed base 12 is installed at the end of one articulated arm 2, and the output shaft 11 is connected to the end of another articulated arm 2; or the fixed base 12 is installed at the end of an articulated arm 2 , the output shaft 11 is connected to the fixing seat 12 of another joint module 1 . Driven by the motor, the output shaft 11 rotates to output torque. The fixed seat 12 is equivalent to the stator. After the output torque, the ...

Embodiment 2

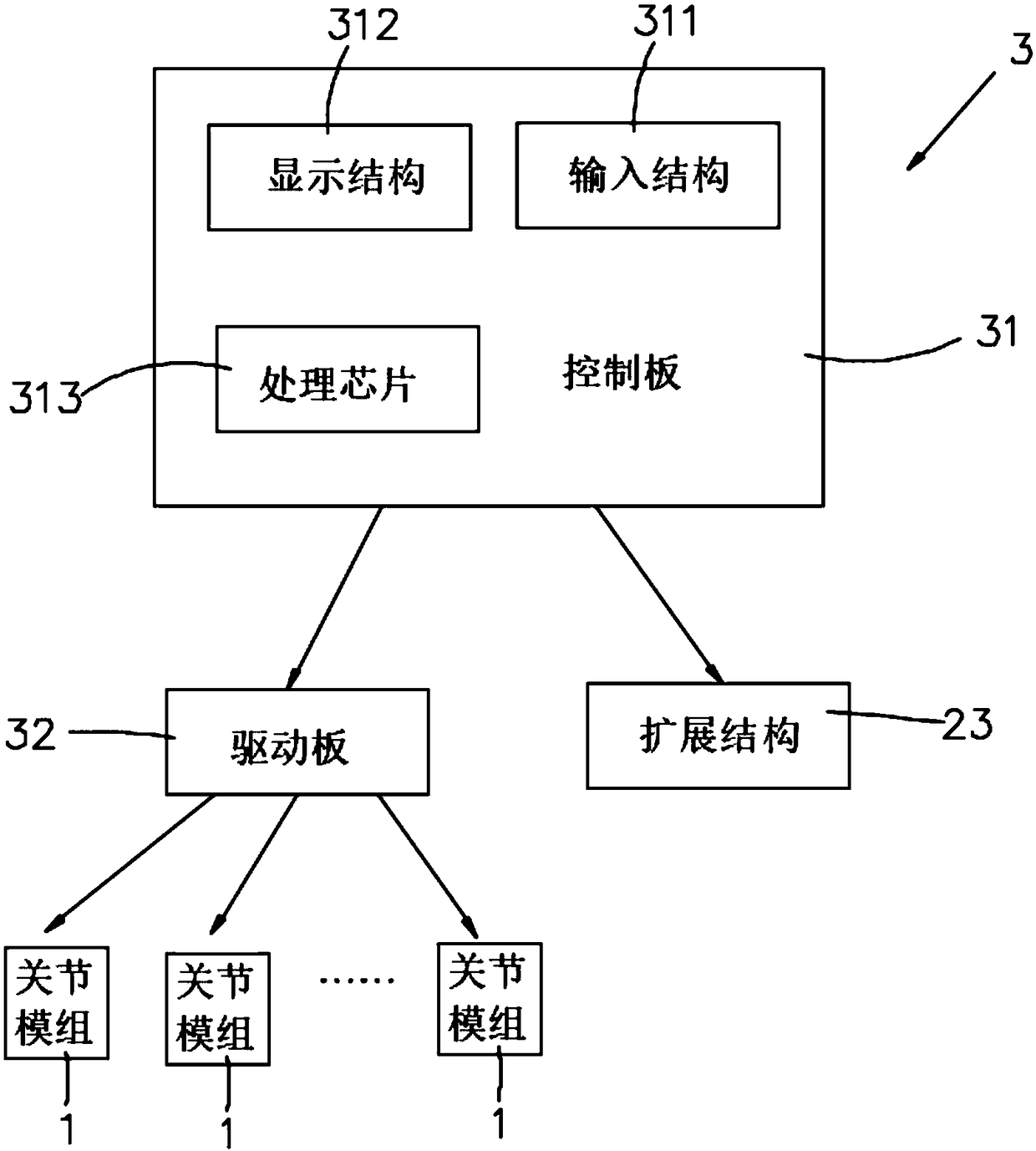

[0037] Such as Figure 1 to Figure 4 As shown, a control method is provided in this embodiment for controlling a joint robot, including:

[0038] Provide preset function modules and logic configuration trees, each function module is used to drive a single motor, and the logic configuration tree has multiple nodes for placing function modules and parameter setting options corresponding to each node;

[0039] Accept the user's setting data for the logical configuration tree and convert it into robot control instructions;

[0040] Transmit control commands to the articulated robot.

[0041] Since the programming of the robot requires a certain learning threshold, the control method provided in this implementation uses a modular programming idea to directly provide functional modules that have been debugged and compiled. Functional modules are placed into nodes of the logical configuration tree. The logical configuration tree itself has a logical sequence. By adjusting the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com