Ultrasonic based automatic winding, welding and cutting machine for plastic spiral supporting tube and using method of ultrasonic based automatic winding, welding and cutting machine

A winding welding and ultrasonic technology, which is applied in the field of ultrasonic plastic spiral support pipe automatic winding welding and cutting machine, can solve the problems of low precision of manual cutting, increased labor cost of products, inability to achieve high efficiency and energy saving, etc., to achieve novel structure and improve production. Efficiency and machining accuracy, the effect of product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

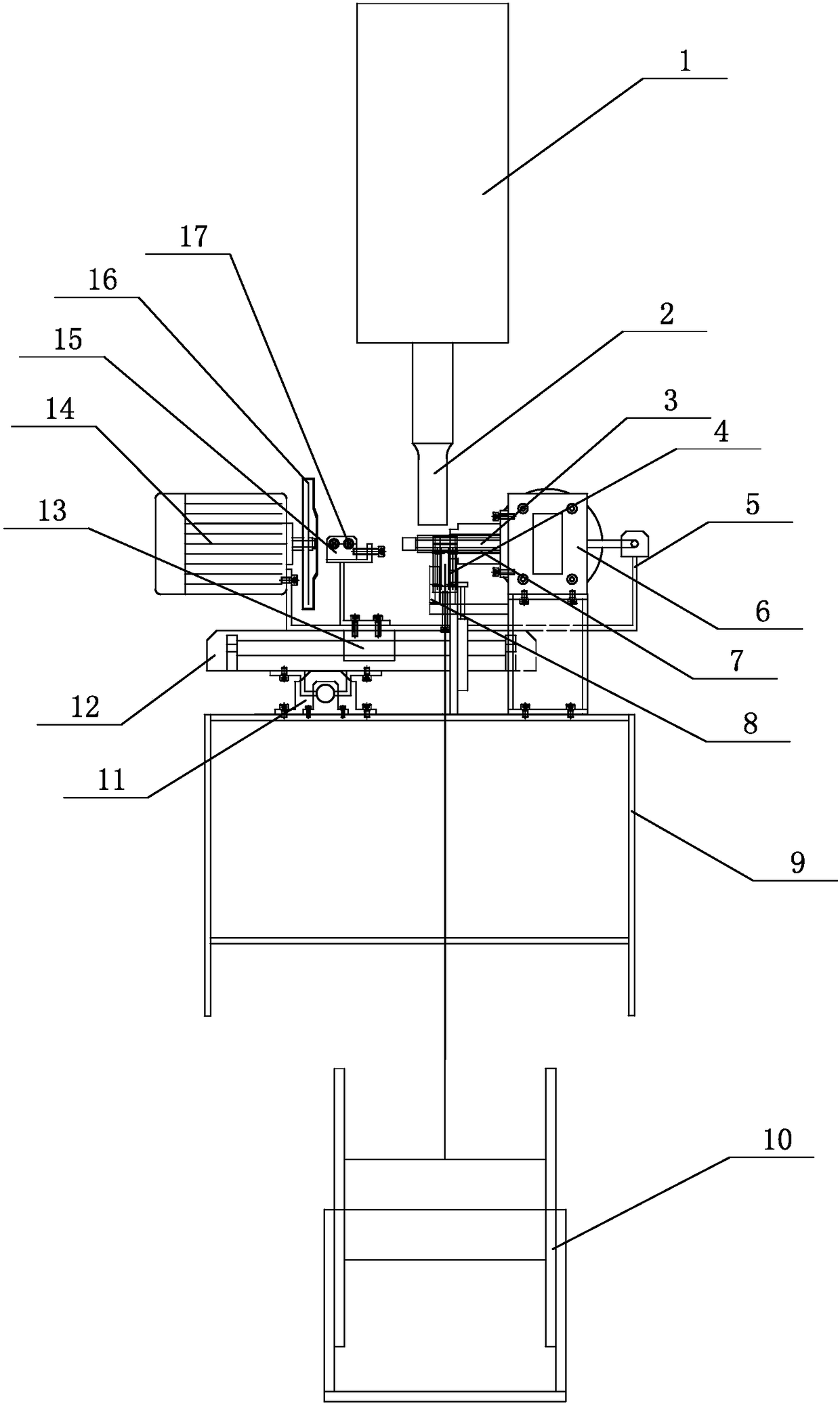

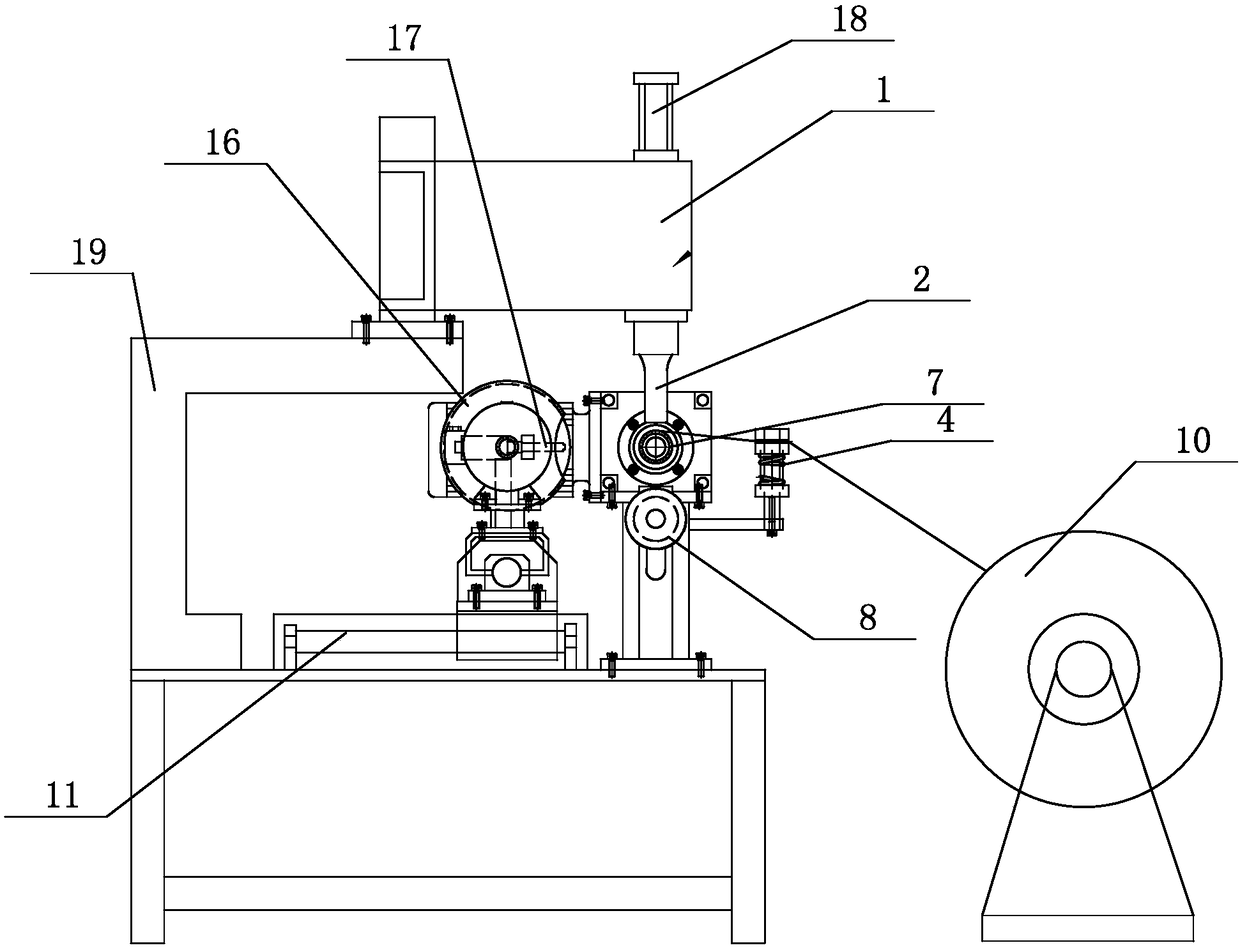

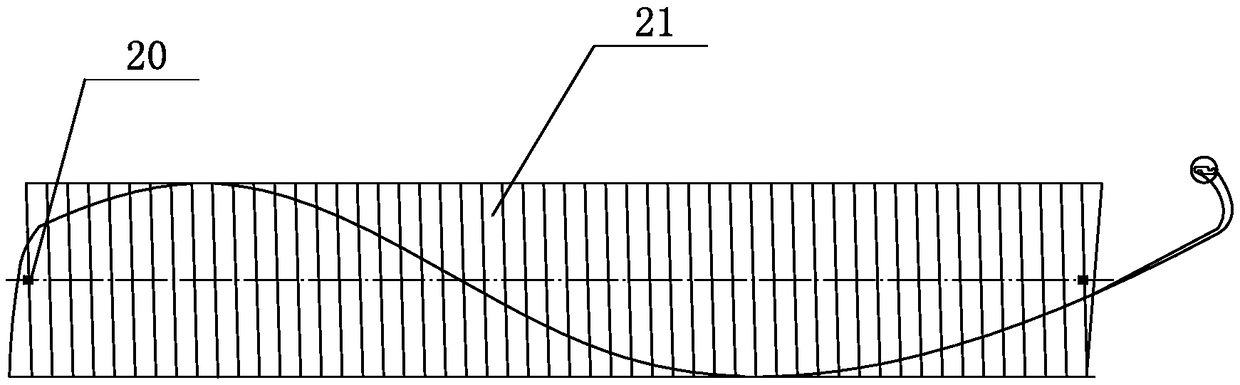

[0029] Such as Figure 1-5 As shown, the ultrasonic plastic spiral support tube automatic winding welding and cutting machine of the present invention includes a material roll 10, a feeding device and a welding and cutting device. The welding and cutting device includes a support frame 9, and the upper ends of the support frame 9 are respectively provided with welding base , welding machine bracket 19 and longitudinal automatic feed guide rail 11, the upper end of the welding base is provided with a speed reducer 6, the middle part of the speed reducer 6 is inserted with the cutter bar 3, and the outer side of the follower cutter bar 3 is provided with a winding mold 7, the follower The left end of cutter bar 3 is provided with stopper, and the position between stopper and winding mold 7 has the gap of certain distance, is convenient to support tube 21 is cut, and the lower side of winding mold 7 is provided with rotary encoder 8, and rotary encoder 8 can Accurately measure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com