Mechanical lifting equipment

A lifting equipment and mechanical technology, applied in the direction of lifting frame, lifting device, etc., can solve problems such as accidents, complex structure of hydraulic lifting device, loss of bearing capacity of hydraulic lifting device, etc., to reduce production costs, reduce structural complexity and ease of use The effect of the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

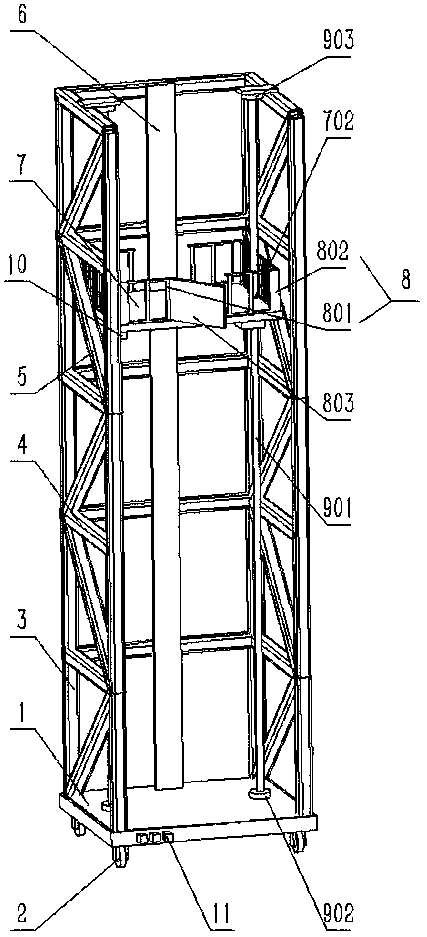

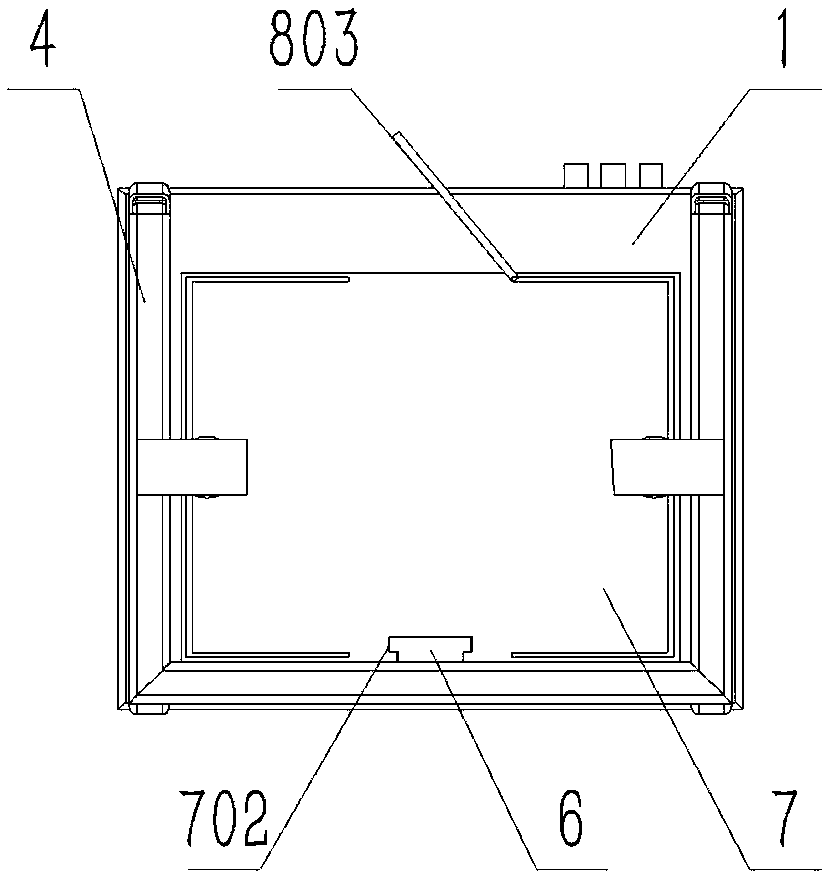

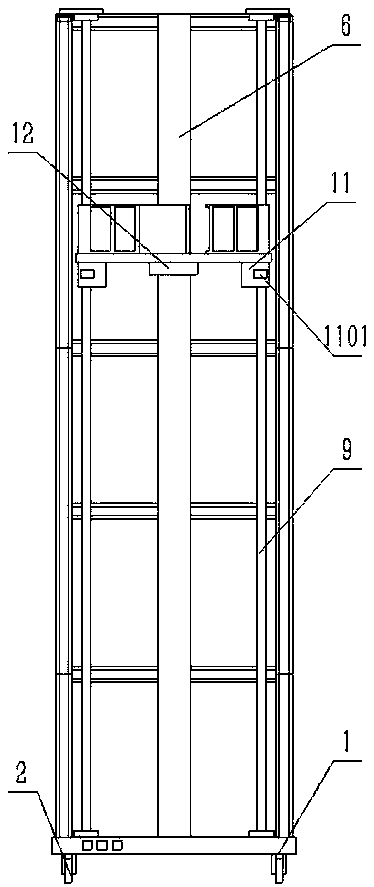

[0024] Please see attached figure 1 to attach image 3 Shown, a kind of mechanical lifting equipment comprises base 1, caster 2, support bar 3, beam 4, diagonal brace 5, guide rail plate 6, lifting platform 7, guardrail 8, lead screw mechanism 9 and rotating motor 10; The base 1 is a rectangular metal plate, and the four casters 2 are respectively arranged on the four corners of the bottom surface of the base 1; the support rod 3 is a square tube, and the four support rods 3 are respectively It is arranged on the four corners of the top surface of the base 1 by welding; the beam 4 is a square tube; several beams 4 are arranged on both sides of the base 1 along the axial direction of the support rod 3 Above the short side and a long side, and the beam 4 is connected with the support bar 3 by welding; the diagonal brace 5 is a square tube, and the diagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com