Multi-layer energy-dissipating concrete-filled steel tube composite column with spliced split panels

A technology of concrete filled steel tube and split plate, which is applied in the directions of columns, pillars, piers, etc., can solve the problems of inability to consume multiple layers of energy, low level of assembly, and insufficient integrity, so as to improve labor productivity, protect safety, and avoid quality problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

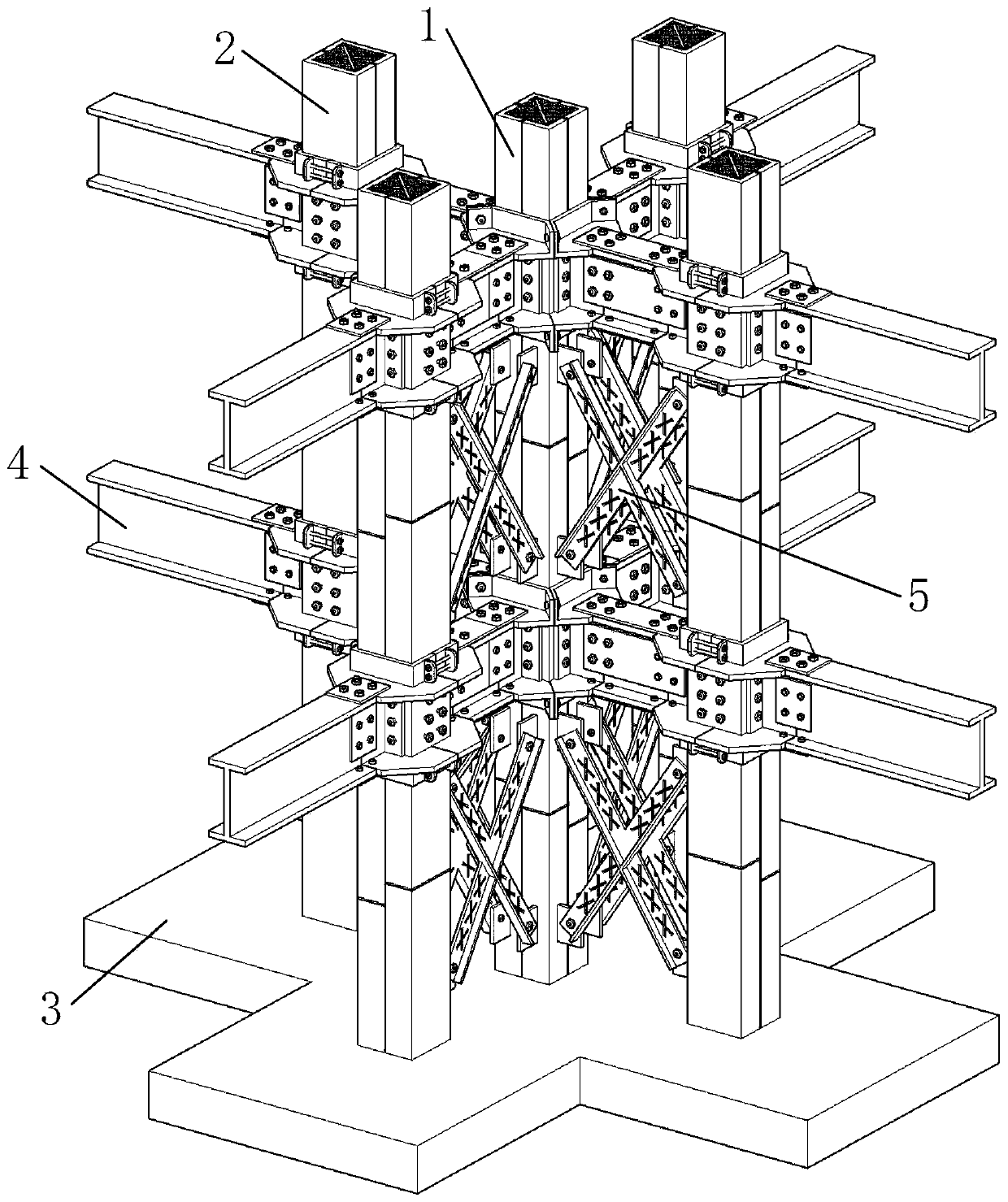

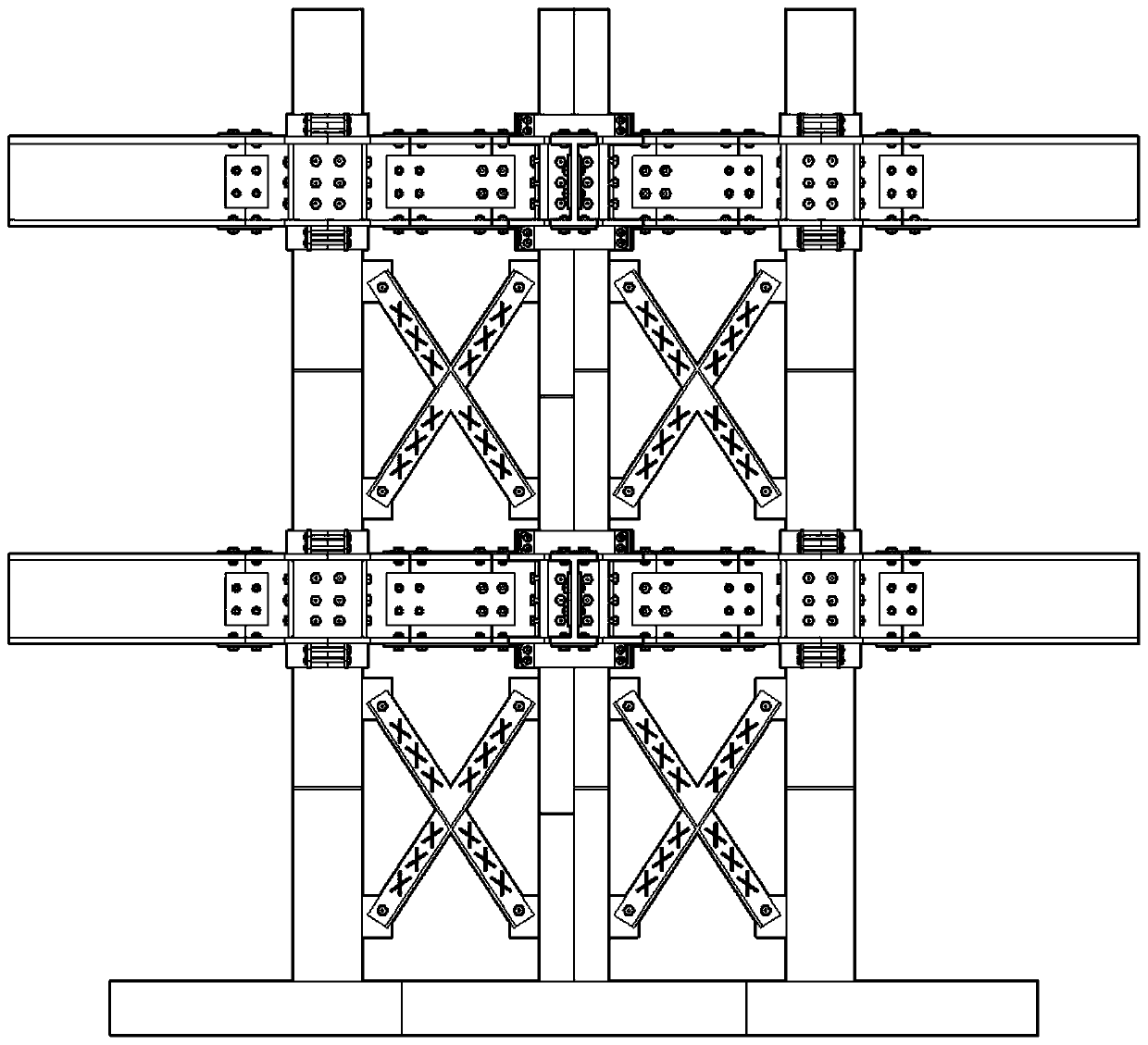

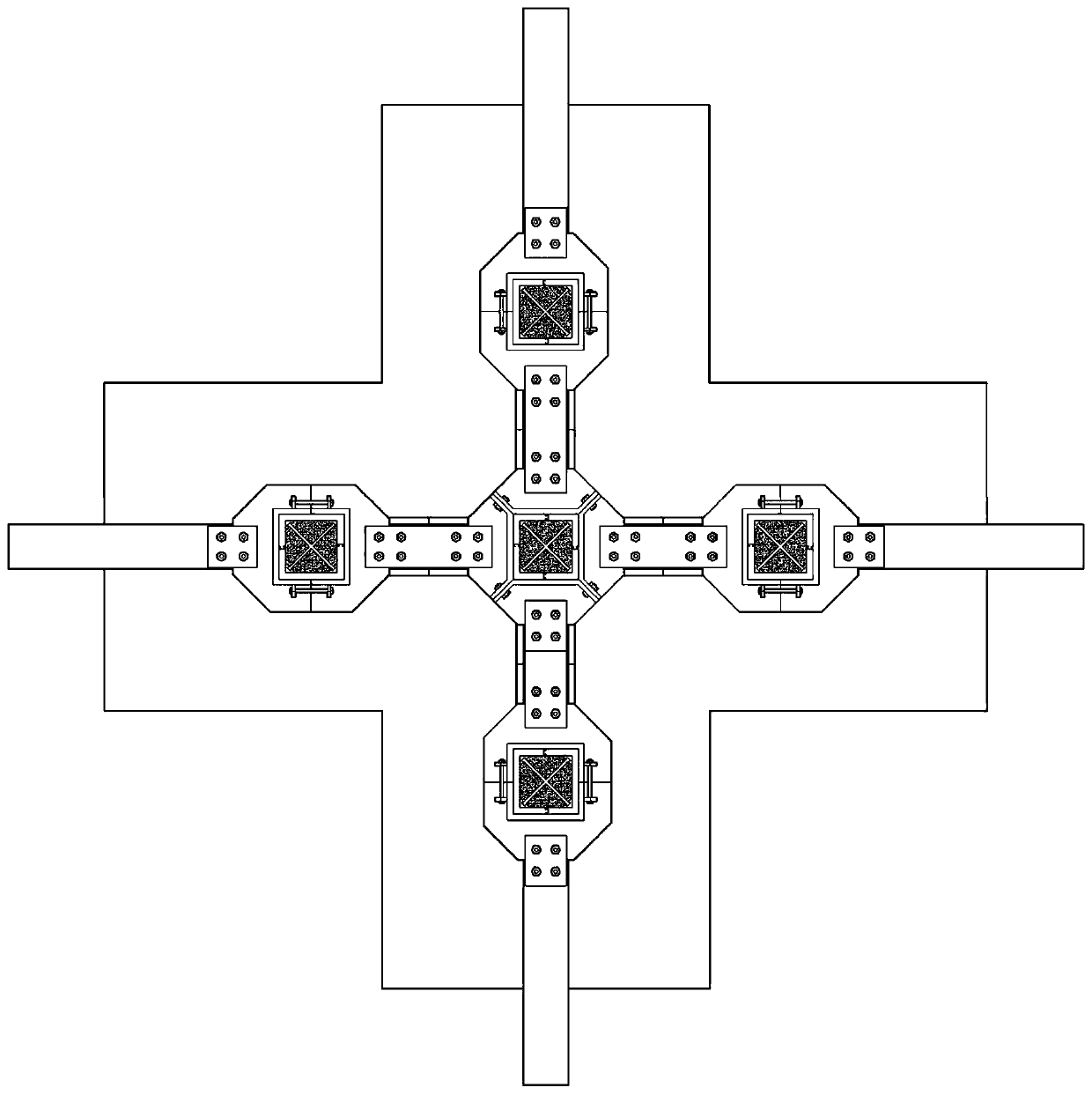

[0030] Such as Figure 1 to Figure 3 As shown, the multi-layer energy-dissipating concrete-filled steel tube composite column of the present invention, which can be spliced with split plates, includes a foundation 3, a fully assembled square steel tube column 1, a semi-assembled square steel tube column 2, an H-shaped connecting short beam 12 and The cross energy-dissipating connector 5, the fully assembled square steel pipe column 1 in the middle and the semi-assembled square steel pipe column 2 located around are fixed on the foundation 3; the fully assembled square steel pipe column 1 and the semi-assembled square steel pipe column 2 are connected via H-shaped connecting short beams 12 to form a composite column; a cross energy-dissipating connector 5 is arranged between the upper and lower H-shaped connecting short beams 12, and one end of the cross energy-dissipating connecting member 5 is connected to a fully assembled square steel pipe Column 1, the other end is conne...

Embodiment 2

[0044] What needs to be explained in this embodiment is that the multi-layer energy-dissipating concrete-filled steel pipe composite column described in the present invention, the fully assembled square steel pipe column 1 and the semi-fabricated square steel pipe column 2 can be assembled in a variety of ways. , the structure is not unique.

[0045] For example, one fully assembled square steel pipe column 1 and four semi-assembled square steel pipe columns 2 are connected by H-shaped connecting short beams 12 to form a "ten"-shaped composite column structure.

[0046] One fully assembled square steel pipe column 1 and three semi-assembled square steel pipe columns 2 are connected by H-shaped connecting short beams 12 to form a "T"-shaped side column composite column structure.

[0047] A fully assembled square steel pipe column 1 and two semi-assembled square steel pipe columns 2 are connected by H-shaped connecting short beams 12 to form an "L"-shaped corner column composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com