High-strength precise ball hinge applied to die-cutting machine

A high-strength, die-cutting machine technology, applied in mechanical equipment, metal processing, shafts and bearings, etc., can solve the problems of high punching force, high punching frequency of die-cutting machine, and die-cutting machine can no longer work normally, and achieves a high level of improvement. The effect of service life and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

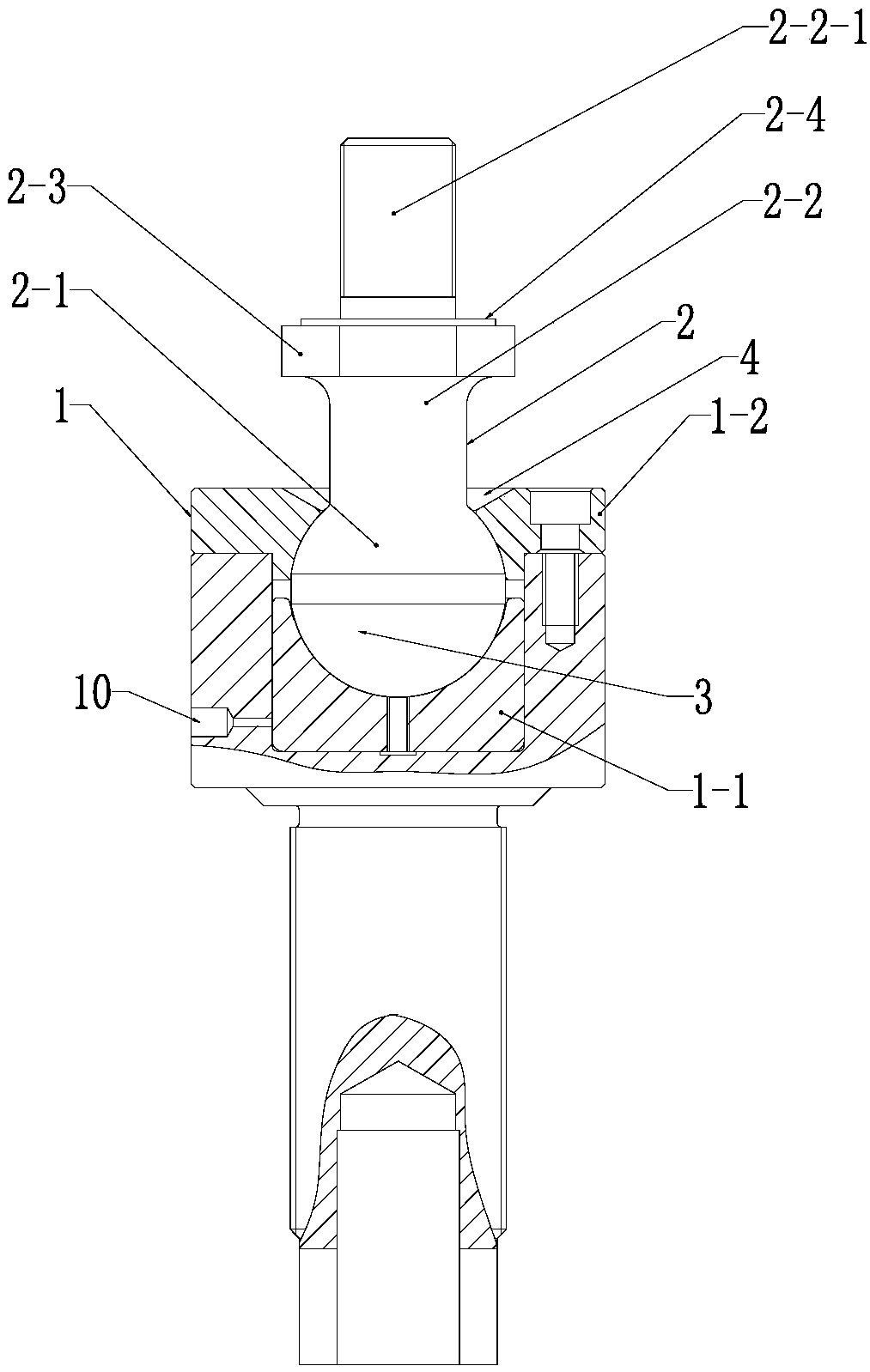

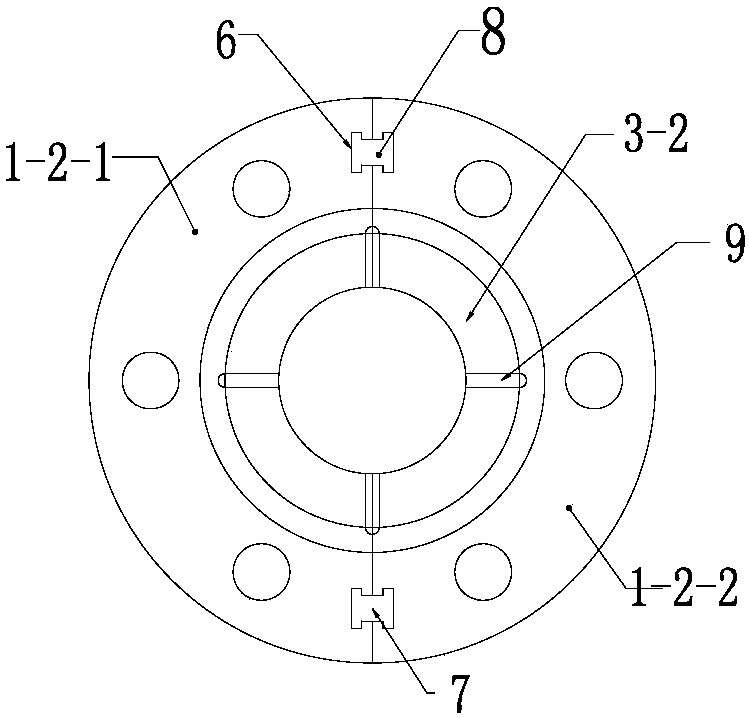

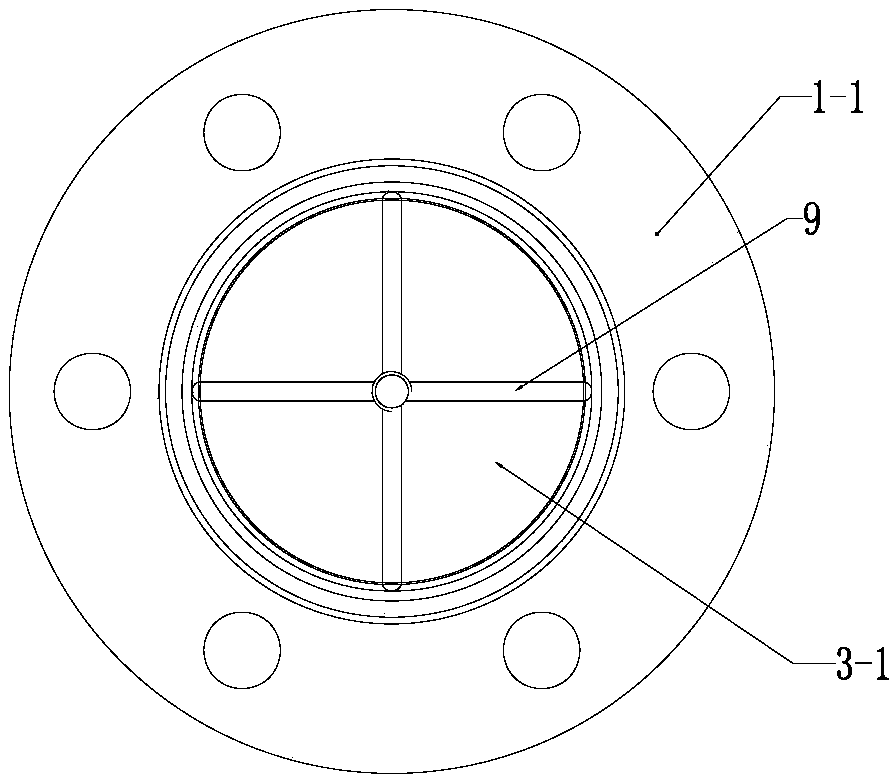

[0031] Such as Figure 1 ~ Figure 4 The high-strength ball hinge applied to the die-cutting machine shown includes a ball socket 1 and a ball head shaft 2. The ball socket 1 is provided with a ball cavity 3, and the ball socket 1 is provided with a tapered hole 4 communicating with the ball cavity 3. , the ball shaft 2 includes a ball head 2-1 that is articulated with the ball cavity 3 and a screw shaft 2-2 that is connected to the ball head 2-1 at one end and has a threaded section 2-2-1 at the other end. The screw shaft 2-2 at the root of the section 2-2-1 extends radially outward to form a thrust ring 2-3 with a diameter larger than the diameter of the screw shaft 2-2, and the end of the thrust ring 2-3 facing the screw shaft 2-2 is A thrust platform 2-4 perpendicular to the axial direction of the screw shaft 2-2.

[0032] By adding a thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap